Description

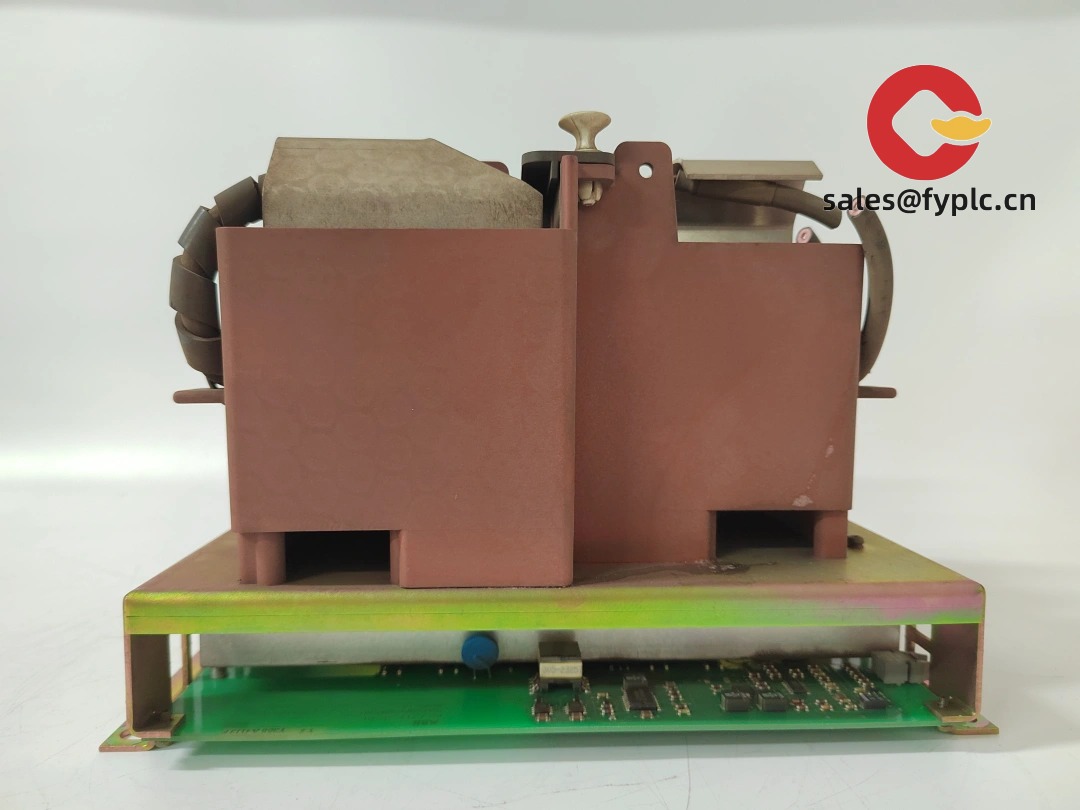

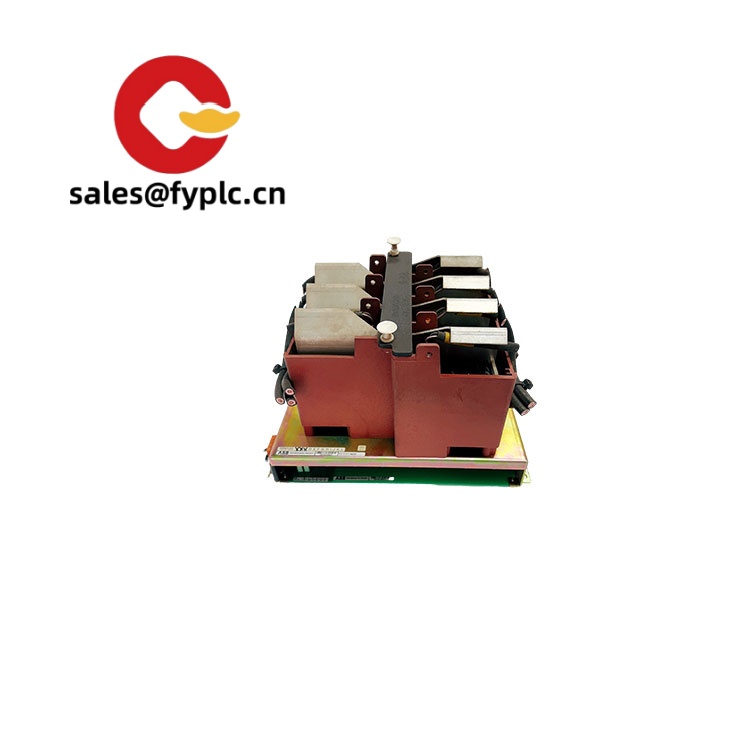

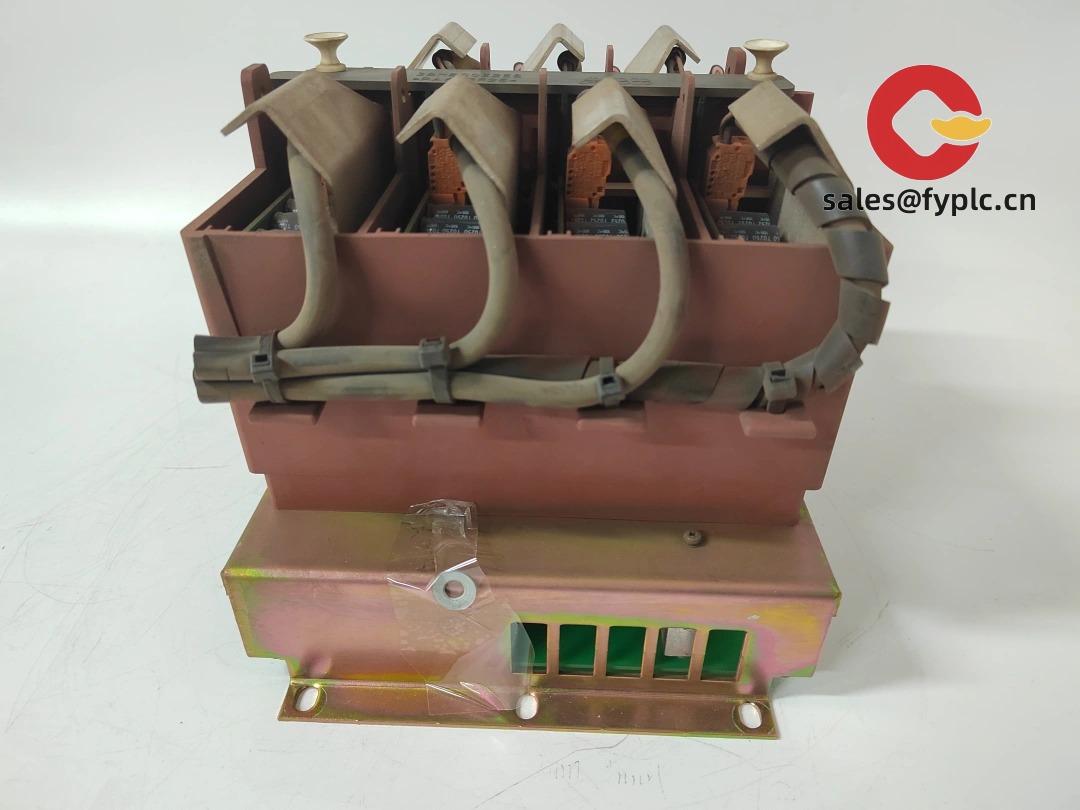

ABB KUC711AE01 (3BHB004661R0001) – Control Board for High-Power/Medium-Voltage Drive Systems

The ABB KUC711AE01, identified by part number 3BHB004661R0001, is a control board used in ABB high-power drive systems, typically medium-voltage platforms and large industrial converters. From my experience with ABB spares, this board sits in the control rack and handles core coordination and protection signals for the power section, making it a straightforward, plug-in replacement when you need to bring a line back online quickly. If you’re maintaining mission-critical assets, you might notice that this series tends to offer stable compatibility across specific drive frames, which reduces the need for reengineering during a swap.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, balance in full before delivery

- Shipping: FedEx, UPS, DHL express options

- Pre-shipment checks: Functional verification and packing inspection to reduce installation surprises

Key Features

- Drop-in replacement for ABB drives: Designed for quick swap-out in ABB high-power drive cabinets to cut downtime.

- Backplane-powered design: No external power feed; the board draws regulated control power from the host system.

- Stable system integration: Works within ABB’s coordinated control architecture for converter and protection logic.

- Industrial robustness: Built for enclosed control cabinets with continuous-duty operation.

- Service-friendly handling: Front-access connectors and defined fixing points simplify on-site replacement.

- Traceable part identity: ABB part number 3BHB004661R0001 helps with lifecycle and inventory control.

- Consistent signal integrity: Board-level routing and grounding practices suited to noisy electrical rooms.

Technical Specifications

| Brand / Model | ABB KUC711AE01 |

| Manufacturer Part No. | 3BHB004661R0001 |

| HS Code | 8538.90 (Parts suitable for apparatus of 85.37) |

| Product Type | Control board for ABB industrial drives/converters |

| Power Requirements | Backplane-supplied control power (no external supply) |

| Operating Temperature | 0 to +55 °C inside a ventilated cabinet (non-condensing) |

| Signal I/O Types | Low-voltage control and protection signals via internal connectors/backplane |

| Communication Interfaces | Board-to-backplane interfaces; no user-accessible field ports on the board |

| Installation Method | Plug-in PCB; mounted in the drive control rack and secured with standoffs/screws |

Application Fields

This board is commonly deployed as a service replacement in ABB medium-voltage or high-power drive systems used in:

- Metals and mining (rolling mills, hoists, conveyors)

- Cement and materials (kilns, raw mills, ID/FD fans)

- Oil & gas and petrochem (compressors, pumps)

- Power generation (boiler fans, feedwater pumps)

- Marine and port cranes (propulsion, winches)

Many maintenance teams keep at least one KUC-series board on the shelf; it seems to be one of those parts that can make or break your restart time after a trip. A customer in a cement plant told us the swap took under an hour, with the longest step being the parameter verification in the control rack.

Advantages & Value

- Reliability: OEM-grade construction for harsh electrical rooms.

- Compatibility: Matches specified ABB drive frames; no wiring rework in normal cases.

- Reduced downtime: Quick installation helps restore production faster.

- Lifecycle support: Extends system life while broader modernization plans are evaluated.

- Traceability & documentation: Clear part numbering supports asset tracking and audits.

- Cost control: Targeted replacement avoids larger cabinet-level interventions.

Installation & Maintenance

- Environment: Mount inside an enclosed, ventilated control cabinet. Keep ambient within 0–55 °C and non-condensing humidity.

- ESD safety: Use grounded wrist straps and antistatic packaging when handling the board.

- Power isolation: Lock out and tag out. Wait for DC bus discharge and verify zero energy before opening the cabinet.

- Backplane seating: Insert evenly to avoid bending; tighten standoffs/screws to manufacturer torque guidance.

- Parameter/firmware: In many cases the drive stores parameters centrally; plan a backup/restore step and match board revision if your site has a strict firmware policy.

- Routine checks: Inspect connectors annually, clean dust with dry air, and confirm tightness of mounting points.

Quality & Certifications

- Manufacturing quality: Produced under ABB quality systems (typically ISO 9001/14001 at the plant level).

- Compliance: RoHS/CE applicability follows the host drive assembly; this part is intended as an internal component.

- Warranty: 12 months coverage from shipment, parts and functional reliability.

Commonly Paired Components

In many ABB installations, the KUC711AE01 works alongside the drive’s control power supply module, I/O extension boards, and (where applicable) fiber-optic gate or feedback modules. If you’re planning a preventative maintenance window, it’s sensible to review the condition of those supporting modules at the same time to avoid repeat stops.

Reviews

There are no reviews yet.