Description

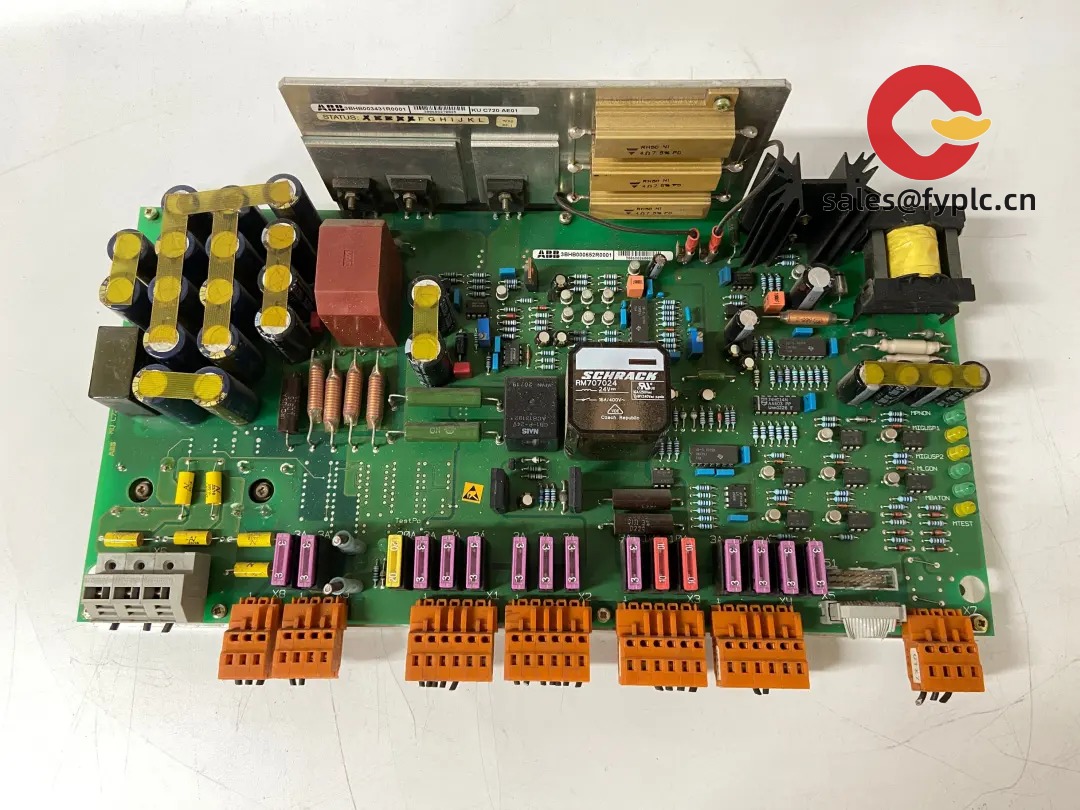

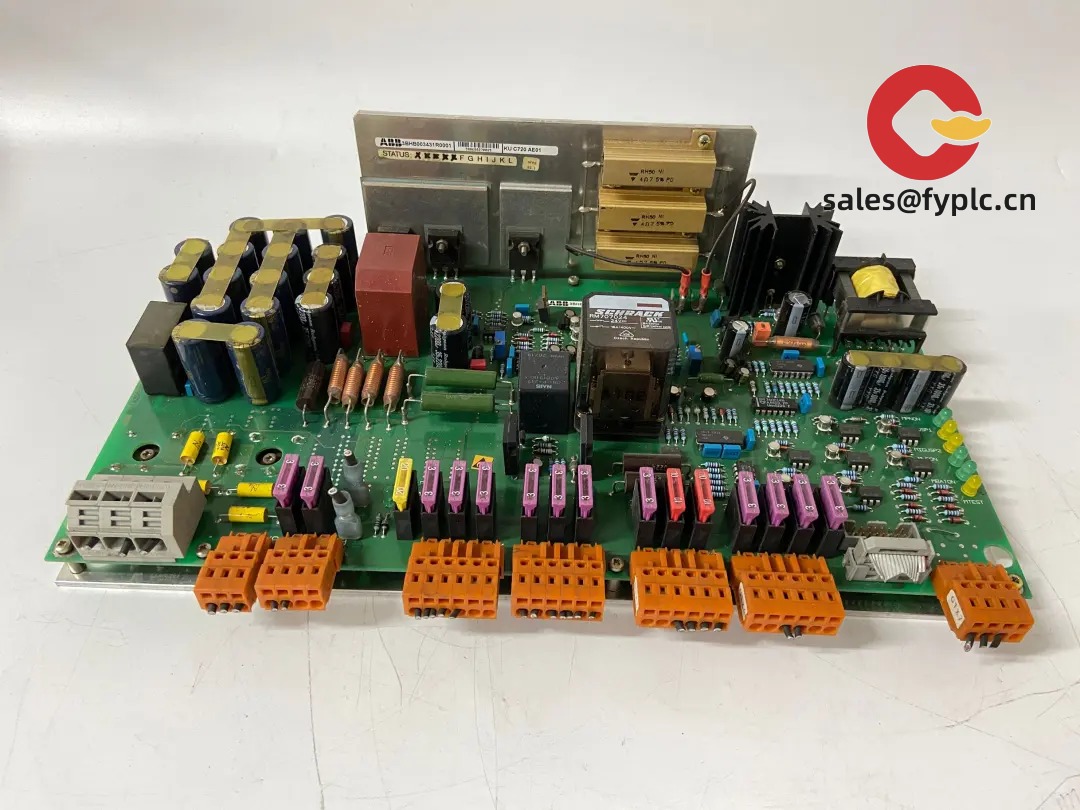

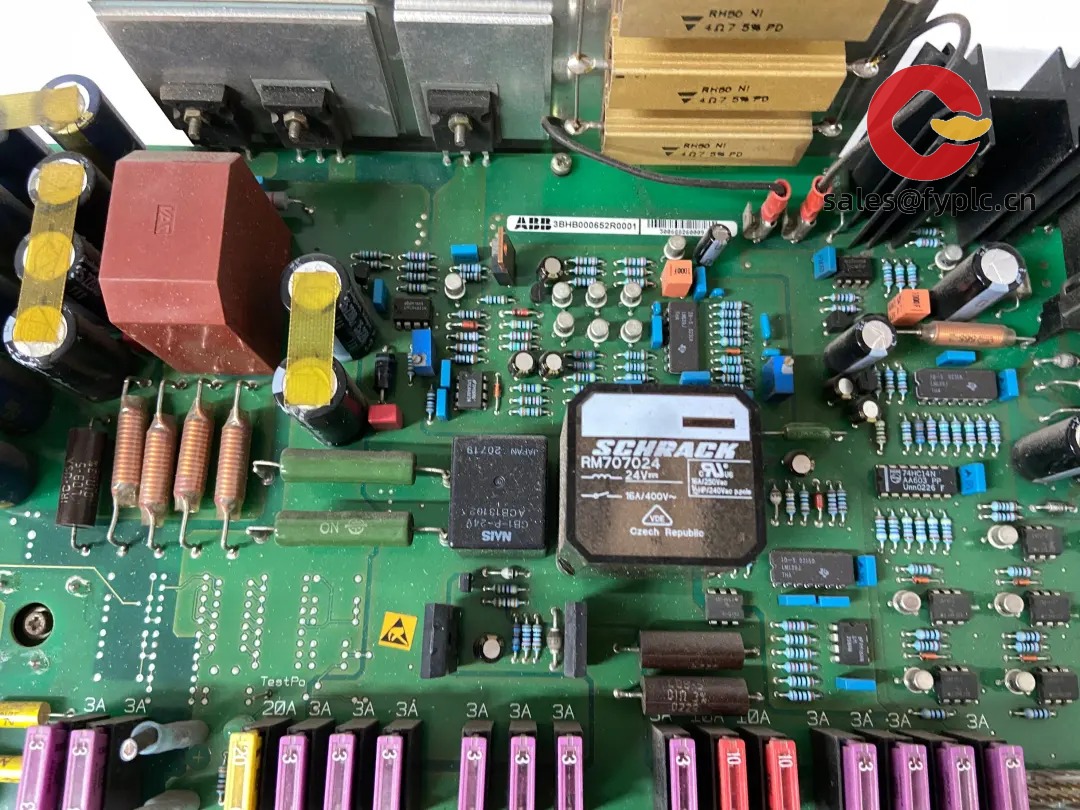

ABB KUC720AE01 (3BHB000652R0001) — Universal Control Unit for AC/DC Motor Protection & Monitoring

One thing I appreciate is how this unit bridges the gap between legacy motor control centers and modern IIoT-ready systems—without forcing a full cabinet overhaul. A customer in northern Germany recently replaced aging Siemens S5-based protection relays with three KUC720AE01s across their conveyor belt drives, and they’ve had zero nuisance trips in 14 months—even during voltage sags down to 72% of nominal.

Key Features

- Adaptive thermal modeling: Tracks real-time motor winding temperature using I²t integration and ambient compensation—not just current thresholds. In many cases, this prevents unnecessary shutdowns during short overloads (e.g., crusher jam recovery).

- Dual power input redundancy: Accepts both 24 V DC (typical for PLC cabinets) and 110–240 V AC/DC (common in MCC rooms). You might notice that the unit stays live even if one supply fails—handy during brownouts or when sharing PSU rails with other modules.

- Embedded Modbus TCP + optional Profibus DP-V1: No gateway needed for SCADA integration. We’ve seen it drop straight into Rockwell FactoryTalk SE environments via standard Ethernet—no firmware hacks required.

- Configurable trip logic with 8 programmable outputs: Not just “trip” or “alarm”—you can assign outputs to functions like “pre-start check failed”, “bearing temp rising >2°C/min”, or “maintenance due in 42 hrs”. One food-processing client uses Output 5 to pulse a pneumatic valve for automatic grease injection.

- Integrated event logger (2,000 entries): Timestamped, with cause codes and pre-event snapshots (current, voltage, frequency). From my experience, this cuts fault investigation time by ~60% compared to relay + separate recorder setups.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB KUC720AE01 (3BHB000652R0001) |

| HS Code | 8536.20 — Electrical apparatus for switching or protecting electrical circuits |

| Power Requirements | 24 V DC ±20% OR 110–240 V AC/DC, 50/60 Hz; max. 12 W (idle), 18 W (active) |

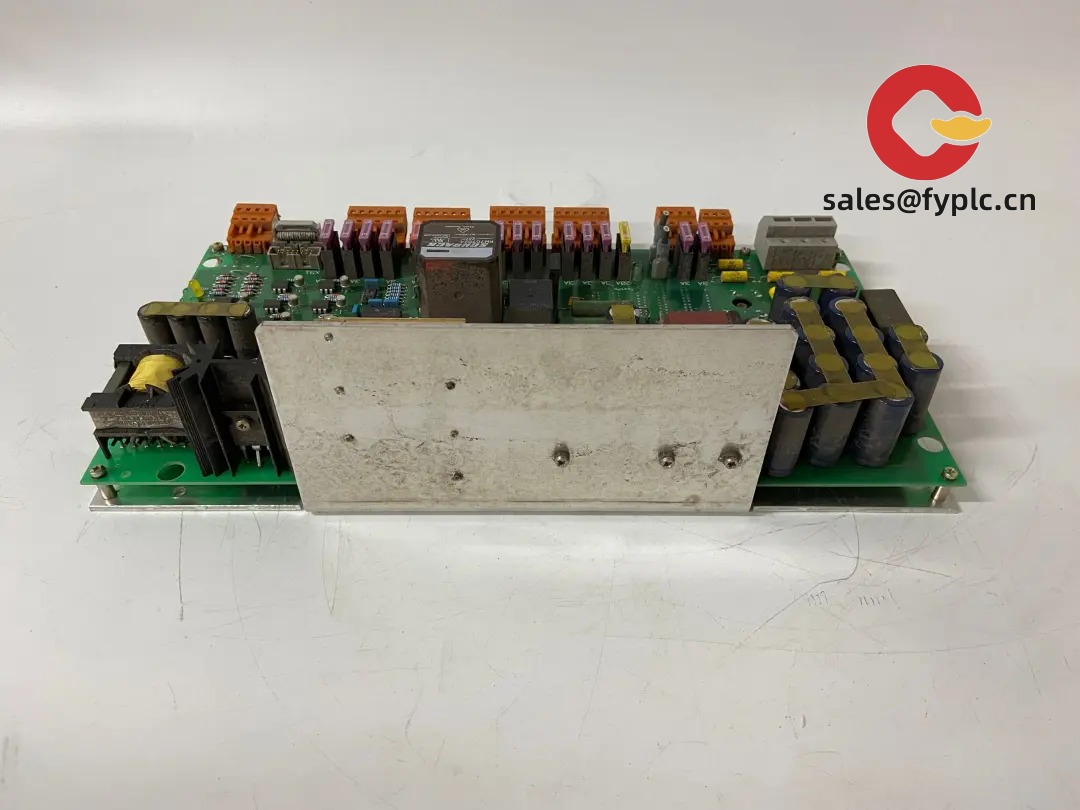

| Dimensions & Weight | 125 × 125 × 145 mm (H×W×D); 1.4 kg |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Inputs | 8x isolated analog inputs (0–20 mA / 4–20 mA, configurable); 6x digital inputs (24 V DC, sink/source) |

| Signal Outputs | 8x relay outputs (NO/NC, 250 V AC / 30 V DC, 5 A resistive); 2x analog outputs (0–20 mA) |

| Communication Interfaces | 1× 10/100 Mbps Ethernet (Modbus TCP, ABB-specific protocol); 1× RS-485 (Modbus RTU, Profibus DP-V1 optional via plug-in module) |

| Installation Method | DIN rail (TS35-15/7.5), vertical or horizontal orientation; IP20 enclosure |

Application Fields

This isn’t just another motor protector—it’s built for places where downtime costs more than the unit itself. Think cement mill feeders handling abrasive limestone dust, wastewater lift stations running 24/7 with fluctuating load profiles, or packaging lines where motor stalling triggers cascading stoppages. It’s also showing up in retrofits on older ABB ACS355 and LSIS iS7 drives, where users need granular thermal tracking but don’t want to replace entire drive cabinets.

Advantages & Value

From a procurement standpoint, the KUC720AE01 avoids the “all-or-nothing” trap. You’re not locked into ABB’s full DCS stack—but you do get certified interoperability with their ACS880 drives and 800xA system. That means fewer compatibility surprises during commissioning. Spare parts are stocked globally (we’ve shipped to Chile and Vietnam within 5 days), and firmware updates come via simple .hex file upload—no special license keys or cloud portals. One plant engineer told us: “We saved €17k last year just by avoiding two unplanned weekend shutdowns—and the diagnostics cut our maintenance labor by half.”

Installation & Maintenance

Mount it in a standard 23″ or 600 mm wide cabinet with ≥100 mm clearance above/below for convection cooling. Avoid direct mounting next to heat-generating devices like variable speed drives—thermal crosstalk can skew the ambient sensor. Wiring: use shielded twisted pair for analog inputs, grounded at the KUC end only. Safety-wise, isolate all power before terminal access—there’s no user-serviceable fuse inside. For routine upkeep: clean vents every 6 months (compressed air works fine), verify calibration annually with a Fluke 754 (±0.1% accuracy suffices), and update firmware whenever ABB releases a patch—usually 2–3 times per year. The unit logs update history, so you’ll know if someone skipped version 3.1.7.

Quality & Certifications

CE (2014/30/EU, 2011/65/EU), UL 508A (Industrial Control Equipment), RoHS 3 compliant, and ISO 9001-certified manufacturing. ABB backs it with a full 365-day warranty—covering parts, labor, and return shipping if defective. No “return authorization required” delays: just email a photo of the fault code and serial number, and we ship replacement same-day (if in stock). Delivery is typically 1 week; worst-case lead time is 4 weeks—even for custom-configured units with Profibus modules.

Order placement note: 50% advance payment confirms build slot and locks pricing. Final 50% clears before dispatch. We ship via FedEx, UPS, or DHL—fully insured, with real-time tracking. No customs brokerage surprises: HS code 8536.20 is pre-cleared for most industrial destinations.

Reviews

There are no reviews yet.