Description

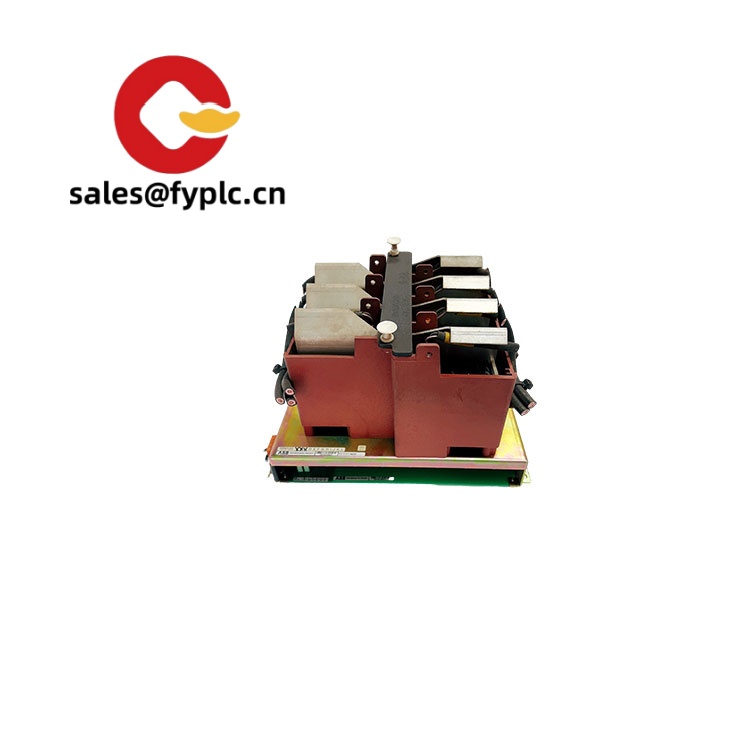

ABB KUC755AE106 (3BHB005243R0106) – IGCT Gate Unit for Medium-Voltage Drive Power Stacks

The ABB KUC755AE106, material code 3BHB005243R0106, is a dedicated IGCT/thyristor gate unit used in ABB medium-voltage drive power cells. From my experience, it’s the go-to replacement when you’re servicing ACS1000/ACS6000 power stacks or similar ABB MV converter sections that rely on fiber-optic firing and robust gate protection. One thing I appreciate is how predictable it is in the field: stable 24 VDC supply, optical command/feedback, and the familiar KUC7xx series layout that maintenance teams already know.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Optical command and feedback – Fiber-optic TX/RX links minimize electrical noise and keep triggering precise, even in harsh MV environments.

- 24 VDC supply architecture – Typically powered from the drive’s auxiliary 24 VDC bus for easy integration and predictable startup behavior.

- Integrated protection logic – Fault detection, gate monitoring, and safe shutdown routines designed to protect the IGCT/thyristor stack during abnormal events.

- Drop-in form factor for ABB stacks – The KUC7xx layout fits common ABB MV drive power modules, reducing replacement time on site.

- Service-friendly indicators – Status LEDs and clear fiber ports help technicians diagnose quickly without guesswork.

- Traceable part identity – Marked with ABB code 3BHB005243R0106, which makes procurement and fleet documentation straightforward.

Technical Specifications

| Brand / Model | ABB KUC755AE106 (3BHB005243R0106) |

| Product Type | IGCT / Thyristor Gate Unit (KUC7xx series) |

| HS Code | 8538.90 (Parts for electrical control equipment) |

| Power Requirements | Nominal 24 V DC supply; typical consumption < 10 W |

| Signal I/O Types | Fiber-optic trigger/enable links; status indication LEDs; fault/contact output (varies by stack) |

| Communication Interfaces | Fiber-optic Rx/Tx to the drive controller |

| Operating Temperature | Typically 0 to +55 °C (cabinet-mounted electronics) |

| Installation Method | Direct-mounted on IGCT/thyristor stack within MV drive power cell; secured with standard fasteners |

| Dimensions & Weight | Compact KUC7xx footprint; commonly under 1 kg (service-friendly size) |

Application Fields

You’ll typically see the KUC755AE106 deployed in ABB medium-voltage drive systems where IGCT-based power cells are used. Common scenarios include:

- Spare/replacement gate unit for ACS1000 / ACS6000 power stacks

- MV variable-speed drives in cement mills, mining conveyors, compressors, and marine propulsion

- Industrial converters where fiber-optic triggering and robust gate protection are mandatory

A maintenance lead in a cement plant told us, “Swapping in the KUC755 saved a shift—no parameter chasing, it just synced with our existing fiber routing.” That seems to be a common theme with this series.

Advantages & Value

- Reliability – Proven KUC7xx platform with protection logic that guards the device and power stack during faults.

- Compatibility – Designed for ABB MV drive cells; in many cases it’s a direct, no-drama replacement when the original unit fails.

- Reduced downtime – Fast shipment and straightforward installation shorten outage windows.

- Traceability and support – Clear ABB material code (3BHB005243R0106) simplifies lifecycle tracking and technical support.

- Cost control – Targeted replacement of the gate unit often restores operation without disturbing the rest of the power cell.

Installation & Maintenance

- Environment – Install inside a clean, ventilated MV drive cabinet. Maintain ambient within typical control electronics range and avoid dust build-up around fiber ports.

- Wiring & optics – Supply stable 24 VDC (observing polarity). Route fiber-optic links with proper bend radius and protect from mechanical stress and oil mist.

- Mounting – Follow ABB torque and ESD handling practices. Ensure the gate unit seats correctly on the stack and fasteners are evenly tightened.

- Safety – Lock-out/tag-out the MV drive, discharge DC link, and verify absence of hazardous voltage before work. Wait the recommended time for capacitors to discharge.

- Routine care – Periodically clean with dry, oil-free air; check fiber connectors for contamination; verify LED status during test runs. Firmware/parameter changes are seldom required on like-for-like replacements.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (ABB production)

- CE-conform design for industrial environments

- RoHS-compliant materials in most configurations

- Warranty: 12 months (365 days)

If you’re replacing an existing KUC7xx in a power cell, share the full part code from the label (including 3BHB005243R0106). Matching the exact revision typically ensures plug-and-play behavior without additional adjustments.

Reviews

There are no reviews yet.