Description

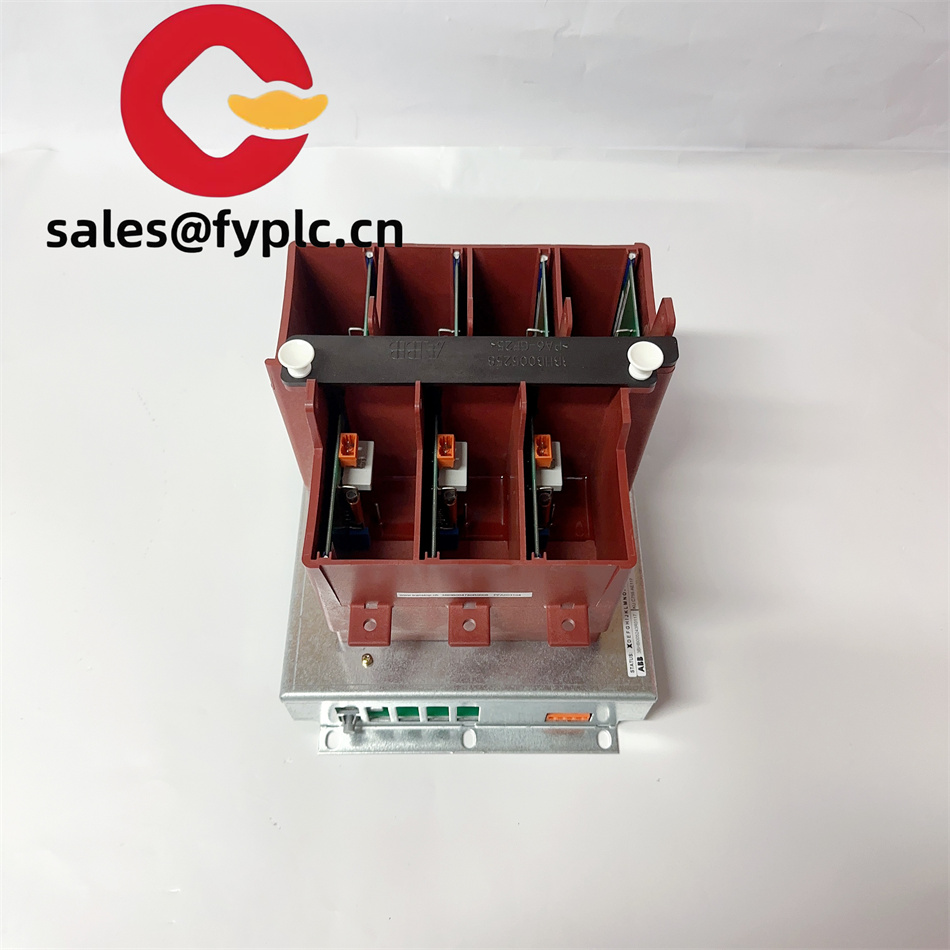

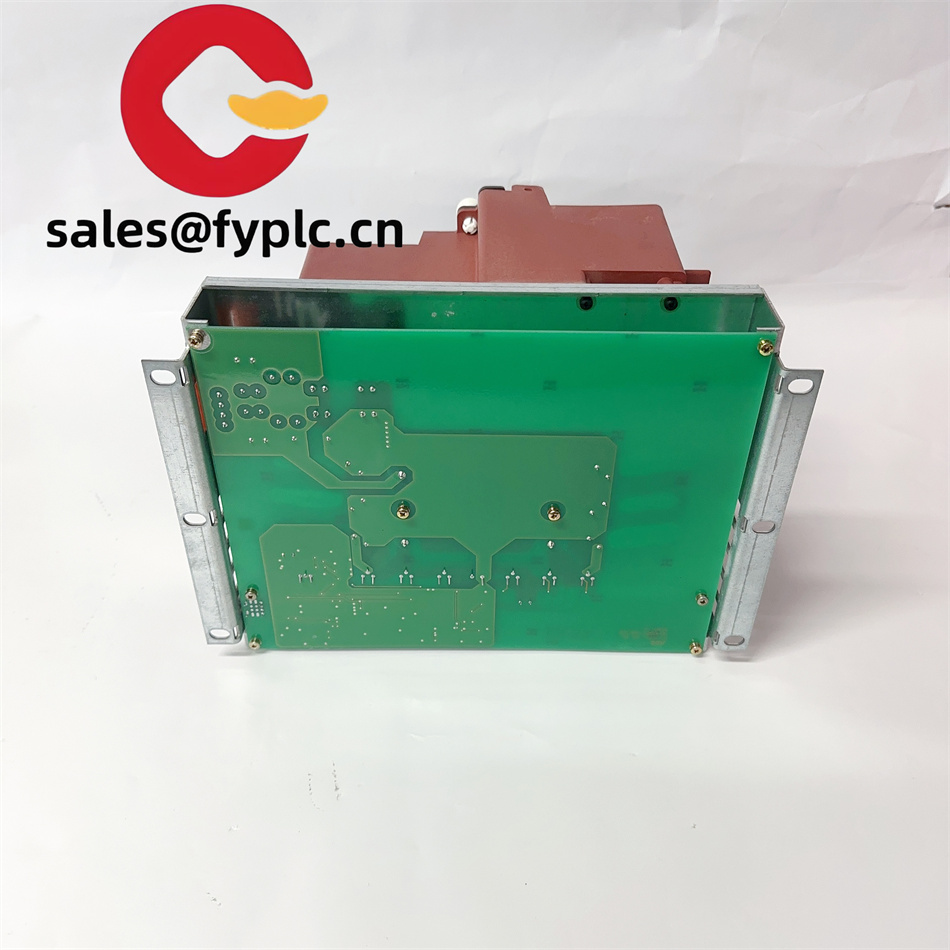

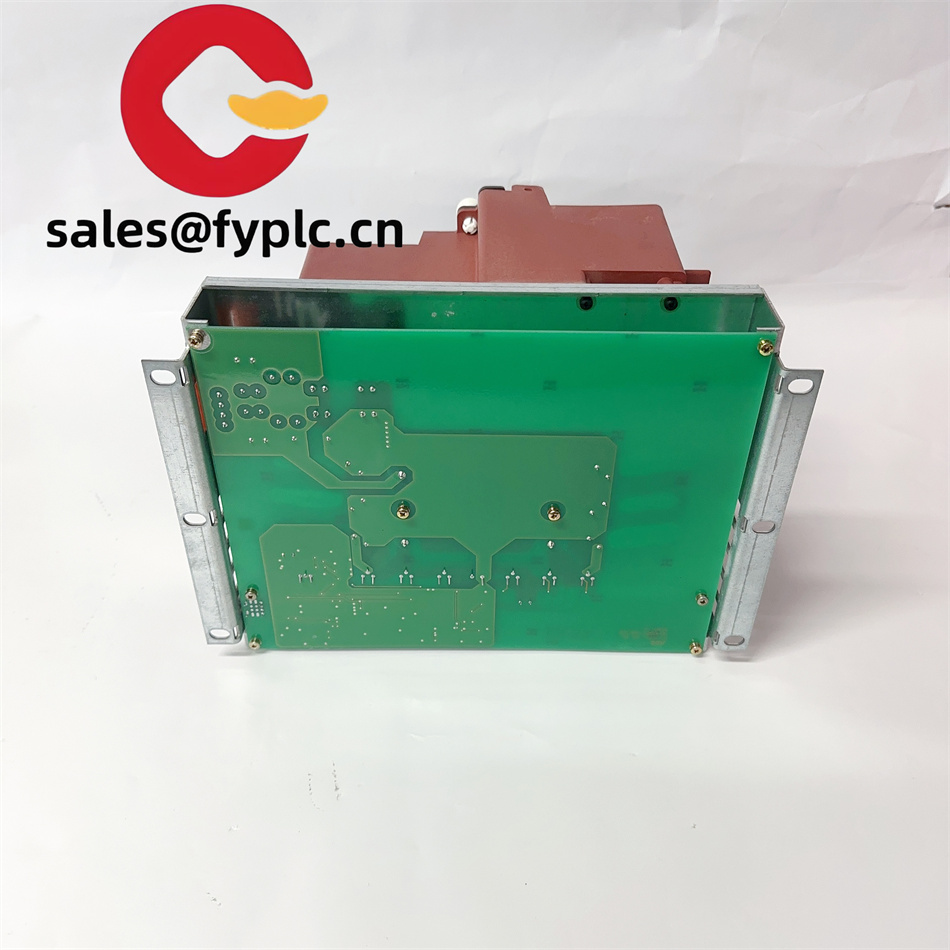

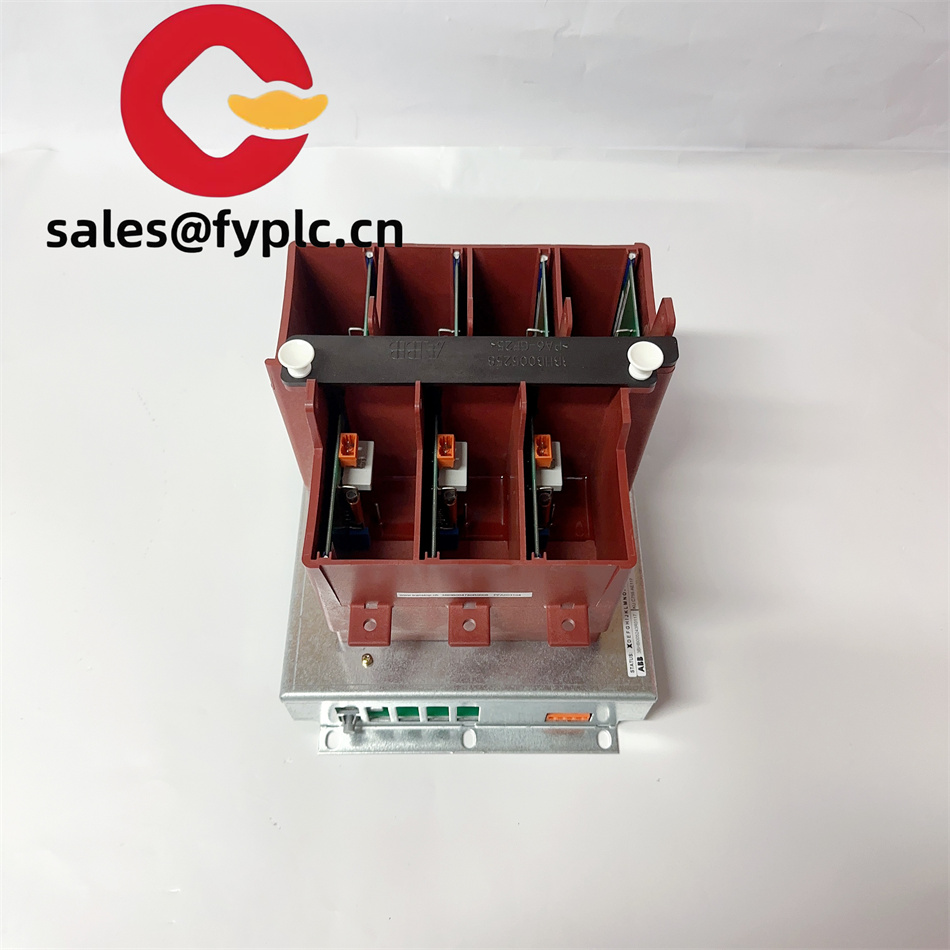

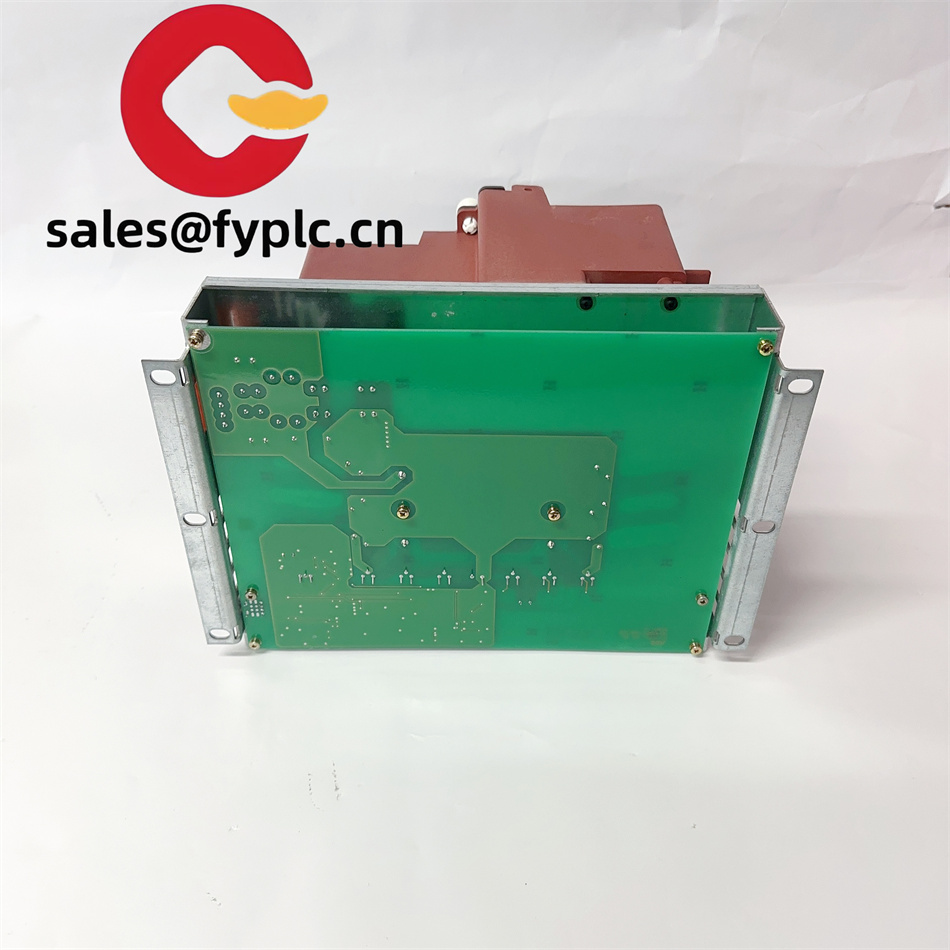

ABB KUC755AE117 3BHB005243R0117 Digital Input Excitation Controller Module

In the realm of industrial automation, ABB’s KUC755AE117 and 3BHB005243R0117 are high-reliability control modules designed to optimize performance in robotic systems, motion control, and distributed industrial applications. These components embody ABB’s expertise in precision engineering and seamless integration, catering to sectors like manufacturing, automotive, and process control.

The KUC755AE117 is a Robot Controller Module part of ABB’s IRC5 controller series, critical for managing robotic arm movements, path planning, and real-time coordination with external devices. It serves as the “brain” of robotic systems, executing complex motion algorithms while ensuring safety and efficiency in tasks like welding, pick-and-place, or assembly.

The 3BHB005243R0117, often classified as a Control Processor Module or I/O Interface, supports ABB’s AC 800M control system. Its role is to handle analog/digital signal processing, communicate with field devices (e.g., sensors, valves), and integrate with supervisory control and data acquisition (SCADA) systems. Together, these modules enable end-to-end automation, from robotic manipulation to process monitoring.

| Label |

Specification – KUC755AE117 |

Specification – 3BHB005243R0117 |

| Model Number |

KUC755AE117 |

3BHB005243R0117 |

| Brand |

ABB |

ABB |

| Type |

Robot Controller Module (IRC5 Series) |

Control Processor/I/O Module (AC 800M Series) |

| Processor |

Multi-core ARM processor @ 1 GHz |

PowerPC or ARM-based (application-specific) |

| Memory |

2 GB RAM, 8 GB Flash |

512 MB RAM, 256 MB Flash |

| Communication |

Ethernet, PROFINET, CANopen |

Ethernet, Modbus, PROFIBUS |

| Input Voltage |

24V DC |

24V DC ±10% |

| Operating Temp |

0°C to 55°C |

-40°C to 70°C |

| Mounting |

Rack-mounted (controller cabinet) |

DIN rail or backplane-mounted |

| Weight |

~3 kg |

~1 kg |

| Certifications |

CE, UL, ISO 10218 (Robotics), IEC 61508 |

CE, UL, ATEX (for hazardous environments) |

| Compatibility |

ABB IRB robots, IRC5 software |

ABB AC 800M, PLCs, and SCADA systems |

- Precision Motion Control: Supports up to 16 axes of motion, enabling high-accuracy robotic trajectories in applications like electronics assembly or medical device manufacturing.

- Safety Integration: Built-in SafeMove2 technology ensures collision detection and emergency stops, compliant with ISO 10218 safety standards.

- Software Flexibility: Compatible with ABB’s RobotStudio® for offline programming, reducing commissioning time and errors.

- Multi-Protocol Connectivity: Seamlessly integrates with legacy and modern systems, ideal for retrofitting or greenfield projects.

- Redundancy Support: Hot-swappable design and dual-power inputs minimize downtime in critical processes like oil refineries or power plants.

- High-Speed Processing: Handles up to 1,000 I/O points with sub-millisecond response times, crucial for real-time process control.

- KUC755AE117: Controls robotic arms in paint shops or body welding cells, ensuring consistent quality and cycle times. Its ability to synchronize with conveyor belts reduces waste from misaligned parts.

- 3BHB005243R0117: Manages sensor data from quality control stations (e.g., vision cameras, torque sensors), triggering alerts for defective components.

- KUC755AE117: In pharmaceutical packaging, directs robots to handle fragile vials or perform sterile filling operations with micron-level precision.

- 3BHB005243R0117: Monitors temperature/pressure in chemical reactors, adjusting valves in real time to maintain optimal process conditions and safety.

- KUC755AE117: Powers autonomous mobile robots (AMRs) for palletizing or inventory sorting, optimizing warehouse efficiency.

- 3BHB005243R0117: Coordinates with barcode scanners and PLCs to manage conveyor systems, ensuring smooth material flow.

- KUC701AE (ABB): Legacy robot controller for simpler robotic applications.

- KUC905AE (ABB): Next-gen controller with AI integration for predictive maintenance.

- 3BHB005240R0111 (ABB): Lower-cost I/O module for basic analog signal processing.

- 3BHB005245R0101 (ABB): Redundant processor module for high-availability systems.

- PM866AK01 (ABB): Compatible CPU for AC 800M systems, offering scalable processing power.

Installation:

- For KUC755AE117, install in a climate-controlled cabinet with filtered airflow to prevent dust accumulation. Ensure proper grounding to avoid ESD damage to sensitive electronics.

- Mount 3BHB005243R0117 on a DIN rail with adequate spacing for heat dissipation. Use shielded cables for analog signals and twisted-pair wiring for PROFINET/Modbus communication.

Maintenance:

- Update firmware quarterly using ABB’s Control Builder software to access new features and security patches.

- For KUC755AE117, calibrate robotic axes annually using ABB’s calibration tools to maintain accuracy.

- Inspect 3BHB005243R0117 for loose connections or corroded terminals, especially in humid or corrosive environments.

ABB offers a standard 1-year warranty for both modules, covering defects in materials and workmanship. Extended warranties (up to 5 years) and ABB Ability™ Condition Monitoring services are available, providing:

- Real-time health tracking via ABB’s cloud platform

- Priority access to spare parts through global distribution centers

- 24/7 technical support for troubleshooting and diagnostics

For more information, please click below to learn more:

Reviews

There are no reviews yet.