Description

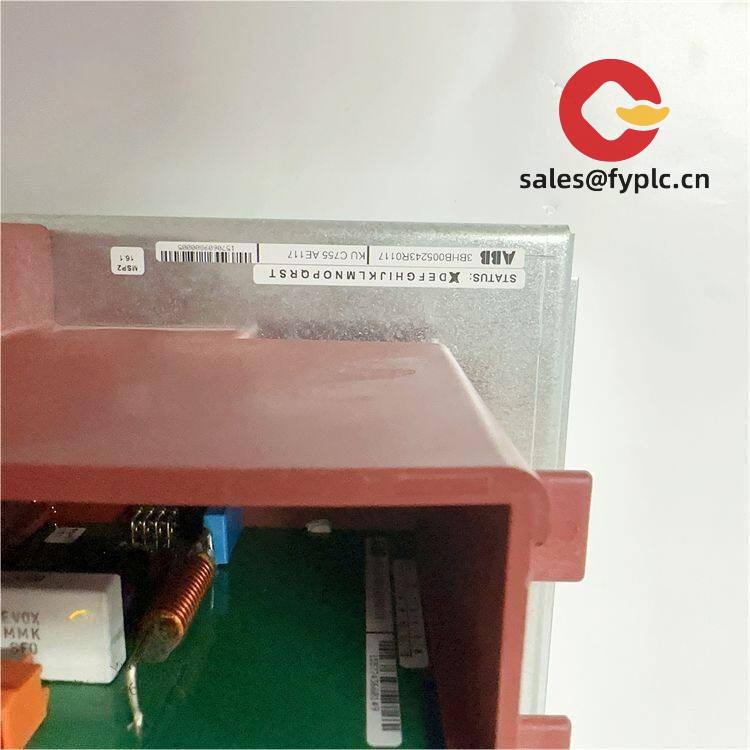

ABB KUC755AE117 Control Board – Reliable Replacement for ACS/Drive System Control

The ABB KUC755AE117 is a factory-style control board designed for ABB variable-speed drive systems. From my experience, this board is typically used as the core control/logic board inside the drive’s control unit, handling real-time motor control, diagnostics, and internal fiber-optic communication with power modules and option boards. If you’re facing drive faults related to control logic, lost fiber links (DDCS), or unstable regulation loops, this model is a straightforward form-fit-function replacement that helps get production back up quickly.

One thing I appreciate is how seamlessly it drops into the existing control slot with minimal parameter changes—most users just back up parameters, swap the board, and restore settings. You might notice that downtime shrinks to a single maintenance window, which in many cases is all that’s needed to stabilize a line or a critical pump.

Order Placement Process and Guarantees

- Warranty: 365 days coverage on the board.

- Lead time: In-stock items ship in about 1 week; no more than one month at the latest.

- Payment: 50% advance payment, balance before delivery.

- Express options: FedEx, UPS, DHL.

Key Features

- Form-fit-function replacement: Designed to replace the original KUC-series control board with no mechanical changes.

- DDCS fiber-optic links: Supports ABB’s high-speed fiber loop for internal drive communications and coordination with power modules.

- Stable control algorithms: Handles motor control, interlocks, and supervision to reduce nuisance trips and speed fluctuations.

- Parameter backup/restore friendly: Works with standard ABB tools and workflows to move parameters back onto the new board quickly.

- Serviceable design: Front-access connectors and keyed plugs make maintenance safer and faster, especially during planned shutdowns.

- Industrial build quality: Board-level construction that, in many cases, includes protective coatings and robust connectors suitable for cabinet environments.

Technical Specifications

| Brand / Model | ABB KUC755AE117 |

| Product Type | Drive control board (logic/control unit module) |

| HS Code | 8538.90 (Parts suitable for apparatus of headings 8535–8537) |

| Power Requirements | Supplied by host drive’s internal 24 VDC control supply (board-level) |

| Communication Interfaces | ABB DDCS fiber-optic internal links; backplane/control-unit connectors |

| Signal I/O | Drive-internal control signals via ABB connectors; interfaces to option boards and feedback as configured |

| Operating Environment | Use inside a sealed control cabinet; follow host drive ambient rating (typically 0 to +50 °C) |

| Installation Method | Direct plug-in board for the designated control slot; ESD-safe handling required |

Application Fields

You’ll typically find KUC-series control boards in ABB medium and low-voltage drive systems supporting continuous‑duty industrial processes. Common applications include:

- Metals and mining: conveyors, crushers, mill stands where uptime is critical.

- Pulp & paper: winders, unwinders, and sectional drives needing precise torque control.

- Water & wastewater: high-reliability pump and blower drives in 24/7 service.

- Chemicals and oil & gas: mixers, compressors, and process fans with tight regulation demands.

- Marine and cranes: hoists and winches where smooth torque and fast response are valued.

“We swapped in a KUC755AE117 during a planned 2‑hour window. Parameters loaded, fiber loop checked, and the line was back to rate by the next shift.” — Maintenance Supervisor, steel processing

Advantages & Value

- Minimized downtime: Fast, direct replacement with familiar ABB workflows.

- Compatibility: Works with existing ABB control units and DDCS infrastructure in most cases.

- Cost control: Extends the service life of installed drives, avoiding premature full-drive replacement.

- Technical support: Parameter handling, fiber diagnostics, and start-up assistance available on request.

Installation & Maintenance

- Cabinet environment: Keep within the host drive’s temperature and humidity limits, with adequate ventilation.

- ESD protection: Use an ESD wrist strap, antistatic mat, and proper handling. Avoid touching component leads.

- Fiber-optic handling: Inspect DDCS fiber ends; avoid tight bends and contamination. Verify Rx/Tx link status after power-up.

- Wiring and grounding: Ensure tight, clean backplane connections; maintain proper control grounding to reduce noise.

- Parameter management: Back up parameters before removal; restore and verify key PID and limit settings after install.

- Preventive care: Periodically clean cabinet filters, check connector seating, and review drive event logs. Firmware alignment with the host system may be required depending on the application.

Quality & Certifications

- Conformity: Typically covered under the drive system’s CE marking; RoHS compliance generally applicable to board-level components.

- UL/CSA: Recognition is usually via the complete drive assembly; use within the intended ABB system to maintain certifications.

- Warranty: 365 days from delivery for defects under normal use.

Recommended Supporting Components

- ABB DDCS fiber-optic cables (host drive compatible) for reliable internal communications.

- Drive-specific mounting hardware and standoffs where applicable.

- ESD-safe maintenance kit for safe handling during installation and service.

- Parameter backup tools/software supported by your ABB drive series.

Need help confirming fit with your exact drive type and firmware? Share the drive nameplate and current board code, and I’ll validate compatibility before you place the order.

Reviews

There are no reviews yet.