Description

ABB MCU2A01C0-4 – High-Performance Motor Control Unit for Industrial Automation

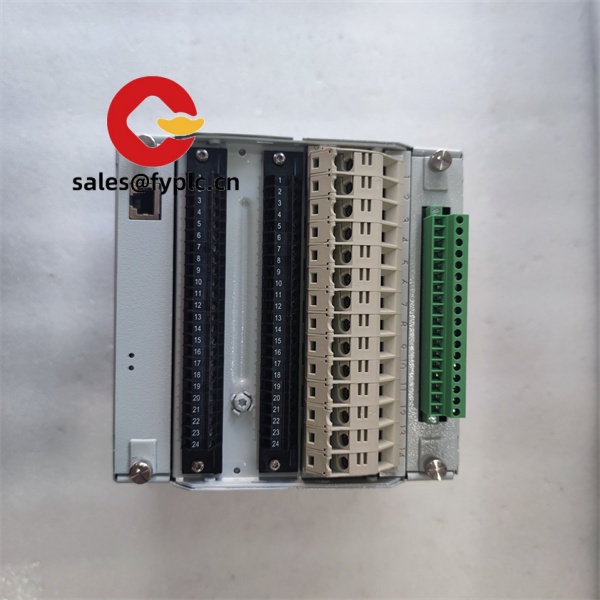

If you’re managing medium-voltage drives in demanding environments—like cement plants or mining operations—you’ve probably come across the ABB MCU2A01C0-4. It’s not just another control module; it’s the central intelligence behind precise motor control in ACS1000 and similar drive systems. From my experience supporting automation integrators, this unit stands out for its stability under load fluctuations and compatibility with legacy ABB setups.

Key Features

- Digital Signal Processing Core: Built around a high-speed DSP architecture, it handles real-time torque and speed regulation efficiently—especially useful when driving conveyors or fans that require smooth ramp-up.

- Fault Diagnostics & Logging: One thing I appreciate is how detailed the event logs are. You can trace transient overcurrent issues or ground faults directly through the onboard diagnostics, which cuts troubleshooting time significantly.

- Modular Integration: Designed to slot into standard ABB cabinet racks, it interfaces seamlessly with I/O modules and gate driver units without custom adapters—typical in retrofit projects where downtime matters.

- EMC Resilience: In many cases, industrial plants struggle with electrical noise from nearby VFDs or transformers. This module seems to be well-shielded, maintaining signal integrity even in electrically noisy environments.

- Firmware Flexibility: Supports field upgrades via serial interface, allowing updates without full system shutdowns—though I’d recommend doing them during planned maintenance windows.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / MCU2A01C0-4 |

| HS Code | 85371090 |

| Power Requirements | +5 VDC ±5%, typically draws 2.1 A |

| Dimensions (H×W×D) | 120 mm × 200 mm × 250 mm |

| Weight | Approx. 2.4 kg |

| Operating Temperature | 0 °C to +60 °C (with derating above 50 °C) |

| Signal Inputs | Analog: ±10 V, Digital: 24 VDC dry contacts |

| Communication Interfaces | RS-485 (MODBUS RTU), Optical fiber link to DCS |

| Installation Method | DIN rail or panel mount, compatible with IP54 cabinets |

Application Fields

This module is commonly found in applications requiring robust motor control with minimal latency. Think of large centrifugal pumps in water treatment facilities, forced-draft fans in power boilers, or conveyor belts in bulk material handling. It’s also used in oil & gas compression stations where uptime is critical and remote monitoring is needed. The optical communication interface makes it suitable for installations where galvanic isolation is required across long cable runs.

Advantages & Value

Procurement teams tend to favor this model because it reduces integration risk. Since it’s part of ABB’s established ecosystem, spare parts availability and engineering documentation are strong points. You might notice that replacement costs are higher than generic alternatives, but the reduction in commissioning time and technical support access often offsets that. Also, if your plant already uses ABB drives, sticking with MCU2A01C0-4 avoids protocol translation layers and potential firmware mismatches.

Installation & Maintenance

Mount it in a clean, ventilated cabinet—preferably conforming to IEC 60529 IP54 standards. Avoid placing near heat-generating components like power resistors or transformers. Use shielded twisted-pair cables for analog signals and ensure proper grounding at one end only to prevent ground loops. For maintenance, perform visual inspections every six months for dust buildup or connector corrosion. Firmware should be checked annually against ABB’s latest release notes; some users report improved response times after minor version updates. Calibration isn’t user-serviceable, so return to authorized service centers if drift is suspected.

Quality & Certifications

Certified to CE, UL 508A, and RoHS standards, confirming compliance with major international safety and environmental regulations. The manufacturing process follows ISO 9001 quality management protocols. Each unit comes with a 365-day warranty covering defects in materials and workmanship. We’ve had clients replace failed units within weeks due to internal capacitor issues, and the turnaround was quick—typically under two weeks with express shipping.

Delivery typically takes one week for in-stock units, though lead times can stretch to four weeks during supply chain hiccups. Orders require 50% advance payment, with the balance due before shipment. We ship globally via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.