Description

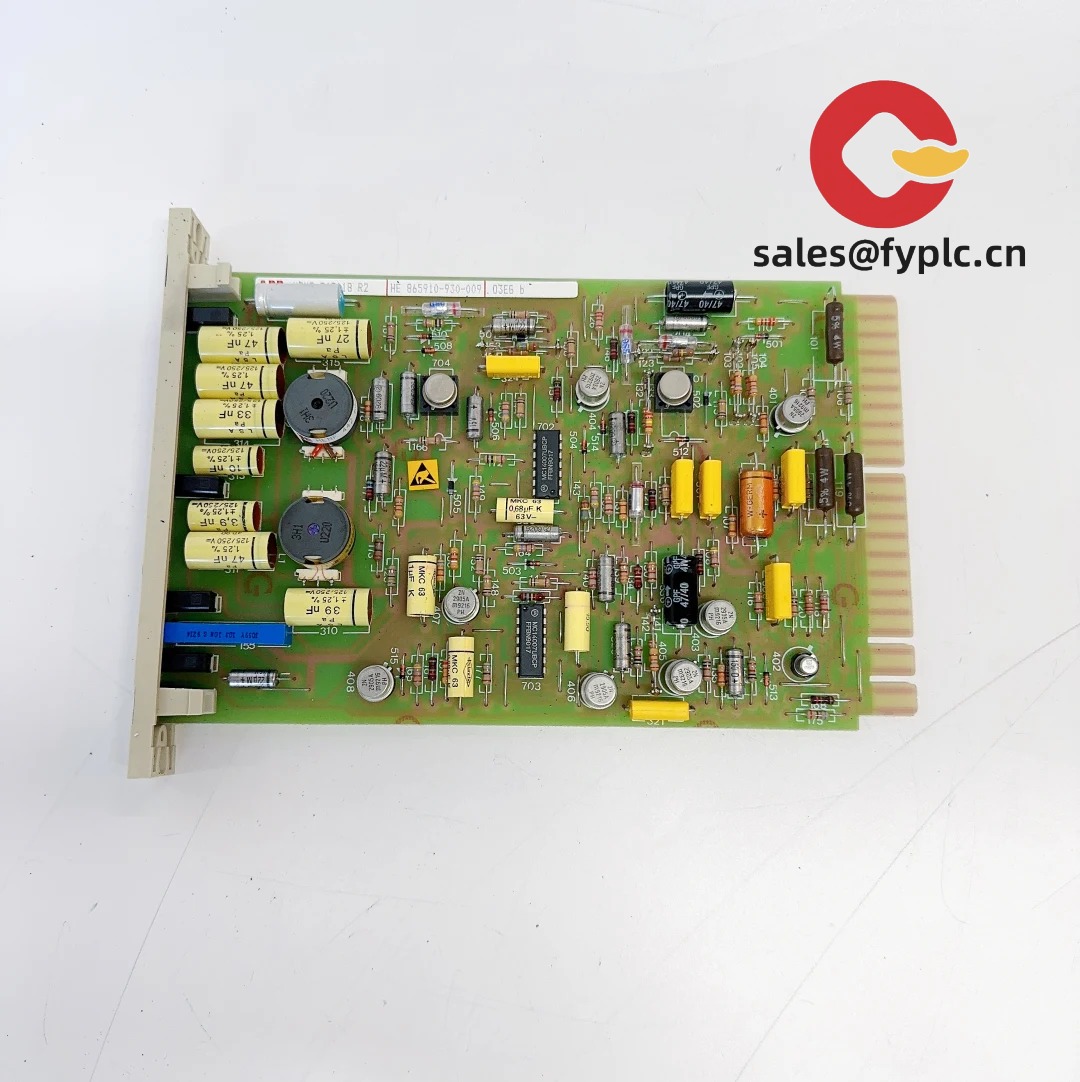

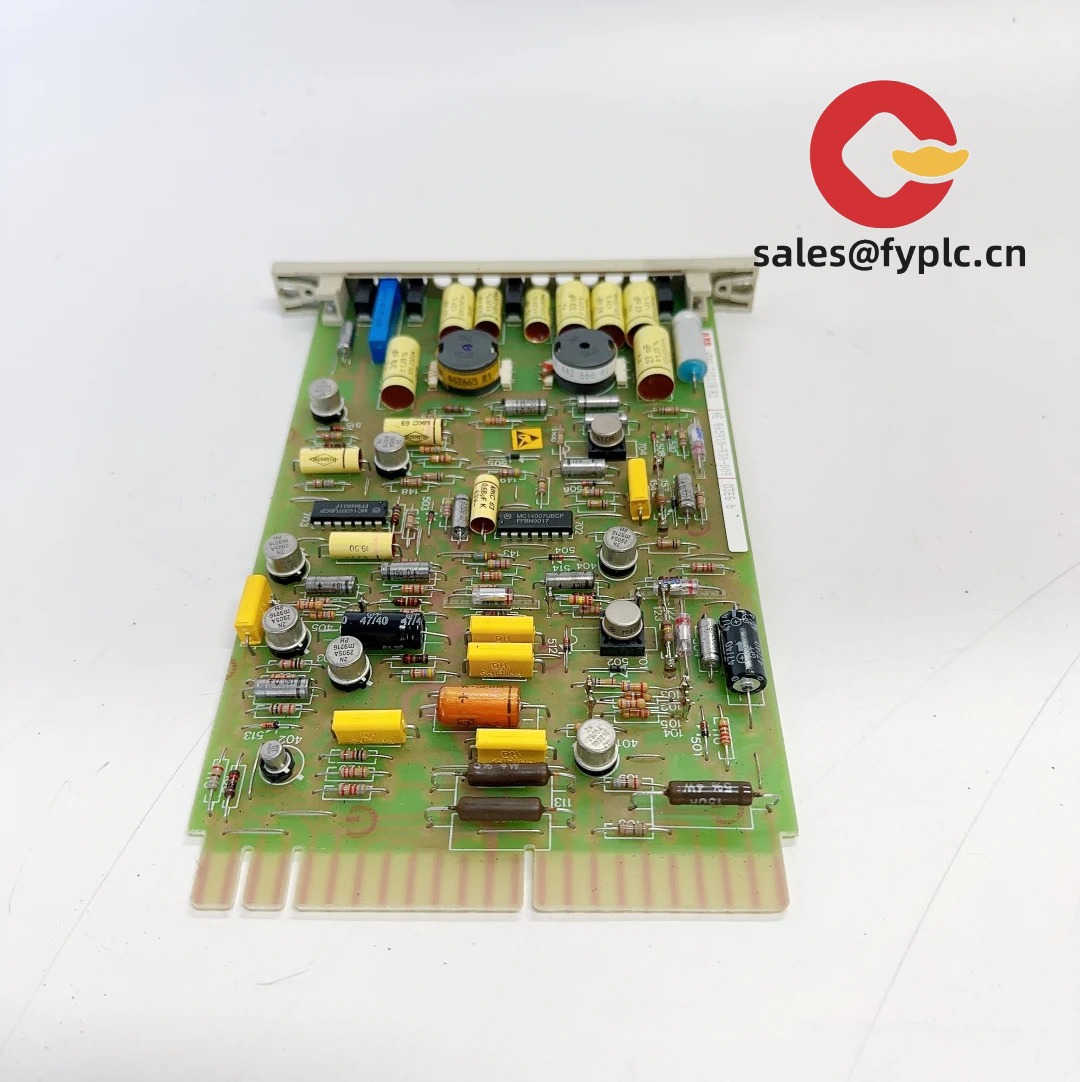

ABB O3EGb (HENF315118R2) – Original ABB operator/selector component for control panels and machinery

The ABB O3EGb, referenced by manufacturer code HENF315118R2, is an original ABB spare designed for dependable panel operation and selector duties. From my experience, this part is typically used as a robust operator element or selector in control cabinets—ideal for start/stop, mode selection, or isolating low-voltage control circuits in machinery and process lines. If you’re replacing a worn operator or standardizing parts across multiple panels, this model helps you keep everything OEM and consistent.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

- Each unit is tested/verified before dispatch, with traceable documentation tied to HENF315118R2.

Key Features

- Genuine ABB part (HENF315118R2) – Ensures form/fit compatibility and consistent performance in ABB-based panels.

- Designed for selector/operation tasks – Commonly used for mode selection, enabling, or isolation in LV control circuits.

- Mechanical, no firmware – No software dependencies; drop-in replacement reduces downtime.

- Panel-friendly construction – Suits standard industrial control cabinets with straightforward wiring.

- Industrial-grade durability – Built for frequent actuation in production environments; feels solid in daily use.

- Traceability – Clear model and manufacturer code help with maintenance records and audits.

Technical Specifications

| Brand / Model | ABB / O3EGb (HENF315118R2) |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | None (passive electromechanical operator/selector component) |

| Dimensions & Weight | Compact, panel-oriented form factor; suited to standard control cabinet layouts (contact us for the exact drawing if needed). |

| Operating Temperature | Typically -25°C to +55°C (application and configuration dependent) |

| Signal Input/Output Types | Mechanical actuation; contact arrangement depends on paired contact blocks (NO/NC as configured) |

| Communication Interfaces | None |

| Installation Method | Panel/cabinet mounting; wiring to control circuit terminals in accordance with ABB instructions |

| Ingress Protection (with proper sealing) | Typically up to IP54–IP65 at the panel face when used with the correct gasket and accessories |

Application Fields

You might notice that O-series operator components like the O3EGb show up anywhere reliable manual control is needed. Typical use cases include:

- Machine tools and packaging lines (mode selection, enabling/disabling subsystems)

- Material handling and conveyors (maintenance/override selectors)

- Process skids and pump panels (local/remote or auto/manual switching)

- Power/control distribution cabinets (isolation/selection of control circuits)

A maintenance supervisor told us they swapped in the O3EGb during a scheduled stop and the panel was back online in minutes—no programming changes, just straight mechanical fit and wiring.

Advantages & Value

- Reliability: Feels solid in daily operation; built for industrial duty cycles.

- Compatibility: OEM fit with ABB panels and accessories reduces retrofit effort.

- Downtime savings: Mechanical part; quick changeover, no firmware to align.

- Support: We provide documentation support tied to HENF315118R2 and assist with equivalent configurations if your panel variant differs.

Installation & Maintenance

- Environment: Install in a clean, dry control cabinet; allow ventilation and avoid direct vibration hotspots when possible.

- Mounting: Panel-mount per ABB guidance; ensure correct orientation and secure tightening torque on the operator and contact blocks.

- Wiring: Use appropriately rated ferrules; separate control and power wiring; confirm NO/NC mapping before energizing.

- Safety: Isolate power and lock-out/tag-out prior to work; verify absence of voltage.

- Routine checks: Periodically inspect mechanical action, terminal tightness, and panel gasket integrity; clean dust/debris from the operator area.

- Updates: No firmware. If contact configuration changes are needed, select the appropriate ABB contact blocks to match your wiring diagram.

Quality & Certifications

ABB operator components like this typically carry CE conformity and, in many cases, cULus and RoHS compliance for major markets. Certification specifics can vary with the exact configuration, so we can provide the datasheet and CoC upon request. Manufacturer policies usually include standard quality assurance; we back this unit with a 365-day warranty for added peace of mind.

Related/Supporting Components

- ABB auxiliary contact blocks (NO/NC) for custom contact arrangements

- Panel sealing gaskets and legend plates (to reach typical IP ratings and clear labeling)

- Terminal blocks and ferrules sized to your control voltage and current

Note: The O3EGb designation and manufacturer code HENF315118R2 identify the exact ABB variant. If your cabinet uses a different cam position or contact layout, share a photo of the nameplate or wiring diagram and we’ll match the right configuration.

Reviews

There are no reviews yet.