Description

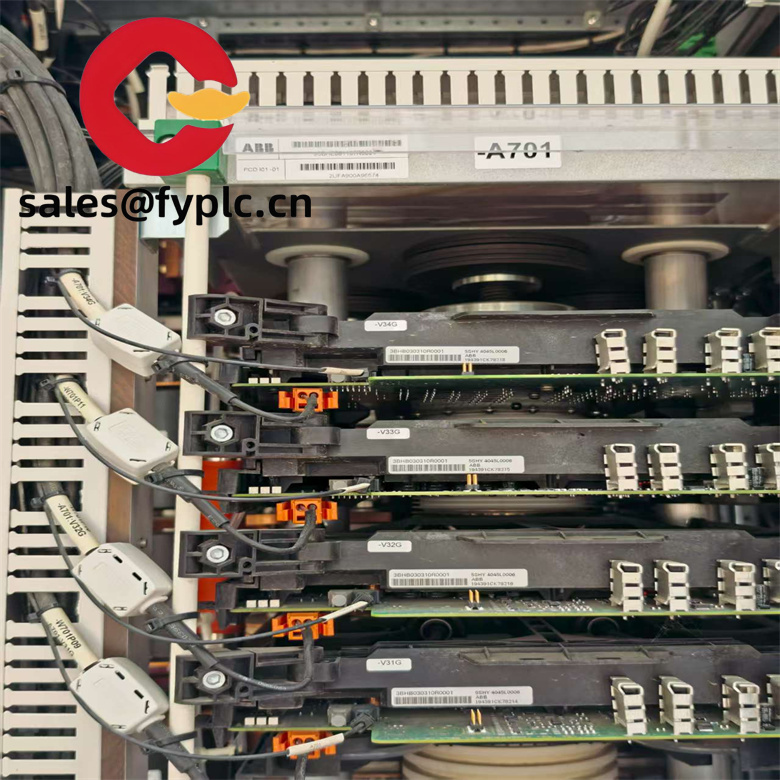

ABB PCS6000 Wind Power Grid Stability Medium Voltage Boost Control Module

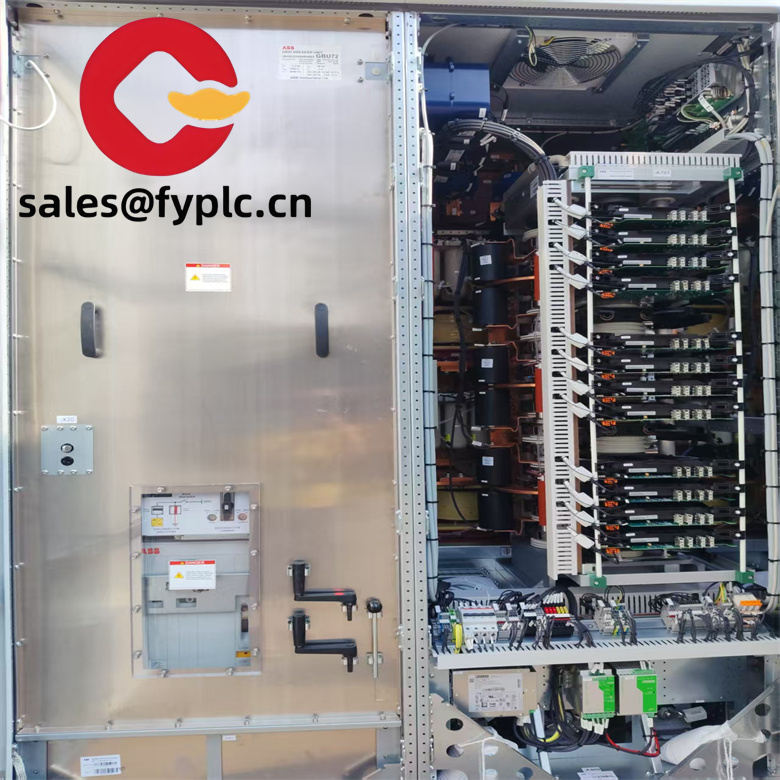

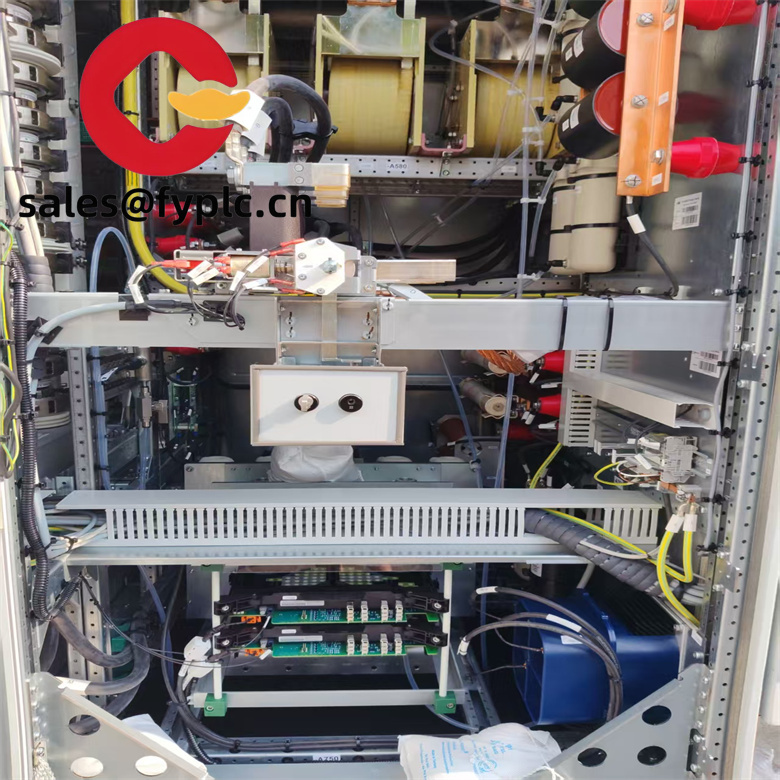

The ABB PCS6000 is a industry-leading medium voltage full-power converter engineered specifically for utility-scale wind energy systems and grid stabilization. Designed to bridge variable-speed wind turbine generators (permanent magnet, induction, or synchronous) with the electrical grid, this 3-level NPC (Neutral Point Clamped) converter transforms variable-frequency AC power into stable, grid-compliant electricity—critical for maximizing energy capture in onshore and offshore wind farms. With a power range of up to 15 MW, the ABB PCS6000 aligns with modern high-capacity turbine designs, making it a staple in renewable energy infrastructure worldwide.

What sets the ABB PCS6000 apart is its rugged, compact IP54-rated cabinet, which integrates liquid cooling, voltage limiting units, and grid interface modules into a space-saving footprint—ideal for turbine nacelles or offshore converter stations. Beyond wind energy, the ABB PCS6000 also serves industrial applications like steel mills and oil pipeline stations, where its dynamic reactive power control mitigates voltage flicker and ensures process stability. For engineers and wind farm operators, this converter isn’t just a component—it’s a solution for reliable, code-compliant power conversion.

| Label | Specification |

| Model Number | ABB PCS6000 |

| Brand | ABB |

| Type | Medium Voltage Full-Power Converter |

| Power Range | Up to 15 MW |

| Nominal Voltage | 3.3 kV |

| Efficiency | >98% at rated load (industry top-tier for wind converters) |

| Cooling System | Closed-loop liquid cooling (supports -25°C to +55°C operation) |

| Operating Temperature | -25°C to +55°C (extreme weather resilience) |

| Communication Protocols | IEC 61850, Modbus, DNP3 (grid-standard integration) |

| Mounting | IP54-rated cabinet (wall/skid-mounted for flexibility) |

| Certifications | DNV-GL GL-IV-2:2012, CGC, IEC 61400-27-1 (global compliance) |

| Grid Frequency Compatibility | 50/60 Hz (dual-frequency for international deployment) |

| Overload Capability | 280% for 10 seconds (handles transient wind surges) |

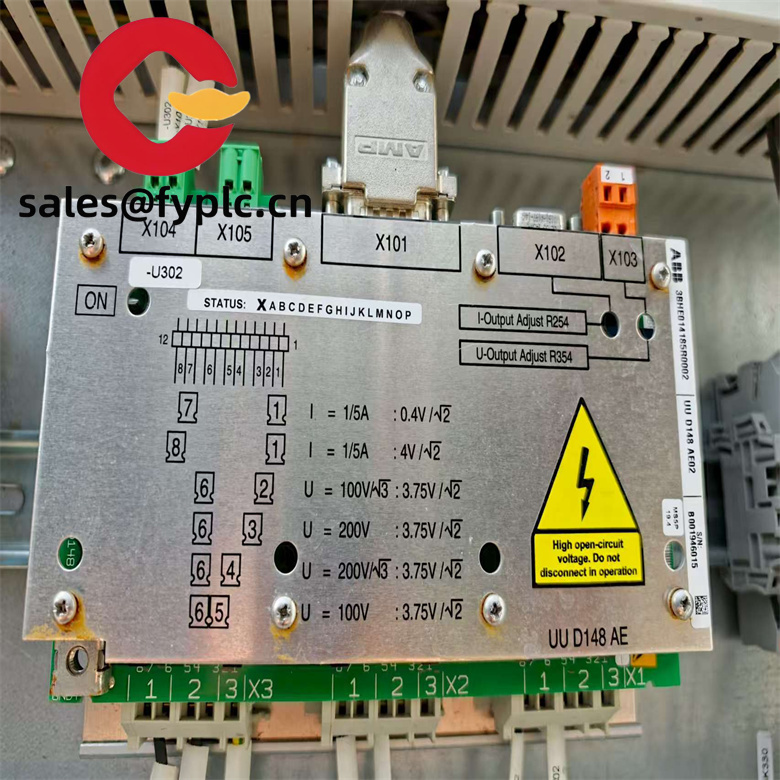

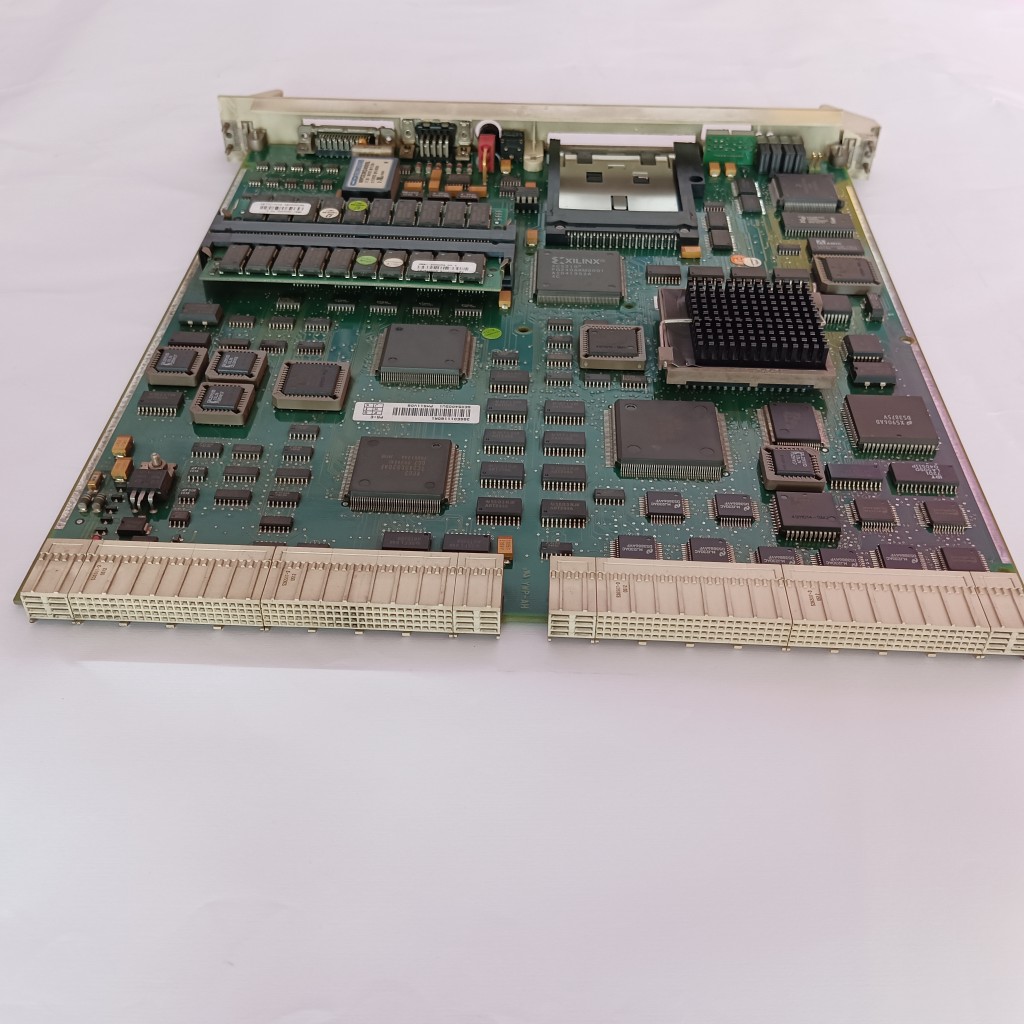

| Topology | 3-level NPC with IGCT (Integrated Gate-Commutated Thyristor) |

| Generator Compatibility | PMG, DFIG, synchronous generators (cross-turbine support) |

The ABB PCS6000 is built for real-world industrial challenges, starting with its fuseless design—eliminating the need for fuse replacements after faults and cutting unscheduled maintenance by 30% compared to traditional converters. Its 4-quadrant operation enables dual functionality: in wind turbines, it converts generator power to grid electricity; in shop-floor testing, it runs turbines in motor mode for rotor positioning and heat-run validation. This versatility reduces equipment costs for turbine manufacturers.

For grid integration, the ABB PCS6000’s dynamic reactive power control (-0.95 to +0.95 power factor) stabilizes weak grids common in remote wind farms, while its grid fault ride-through (FRT) capability keeps turbines online during voltage dips—complying with strict standards like Germany’s BDEW and China’s GB/T 19963. Advanced drive train damping technology also decouples mechanical stress from grid fluctuations, extending turbine gearbox lifespan by up to 20%. Operators report 5-8% higher annual energy production thanks to the converter’s precise maximum power point tracking (MPPT) algorithm.

Industrial Use Cases & Value Scenarios

In offshore wind farms—where reliability and space are non-negotiable—the ABB PCS6000 thrives. For example, a 500 MW North Sea wind farm integrated 40+ ABB PCS6000 units, and their corrosion-resistant design (salt-spray tested to IEC 60068-2-52) reduced maintenance visits by 45% compared to competitors. During a 2023 grid voltage dip, the converters’ FRT capability kept turbines operational, avoiding $600,000 in lost revenue.

Onshore, the ABB PCS6000 solves weak grid challenges. A 300 MW wind farm in India used the converter to provide reactive power support, eliminating load shedding for nearby rural communities and earning grid operator incentives. In industrial settings, a Texas steel mill deployed the ABB PCS6000 STATCOM variant to mitigate arc furnace voltage flicker, cutting production downtime by 18% and improving steel quality consistency. These use cases highlight why the converter is a top choice for industrial automation and renewable energy integration.

Compatible and Related Models

- ACS6000– ABB’s medium voltage drive sharing the ABB PCS6000’s IGCT technology, ideal for industrial motor control (e.g., pump/compressor systems).

- PVS800– Solar inverter complementary to the ABB PCS6000 for hybrid wind-solar projects.

- STATCOM PCS6000– Grid stabilization variant delivering ±12 Mvar reactive power (used in oil/gas pipeline stations).

- AC 800 PEC– Advanced controller pre-configured for real-time ABB PCS6000 monitoring and tuning.

- ACH580– Variable speed drive for wind turbine auxiliary systems (cooling fans, pitch controls) that syncs with the PCS6000.

- ZIF-4000– Interface module enabling ABB PCS6000 integration with SCADA systems for predictive maintenance.

Setup & Service Guidance

Installing the ABB PCS6000 requires aligning its liquid cooling system with turbine specs: target flow rates of 8–12 L/min and inlet temperatures <35°C to maintain >98% efficiency. The IP54 cabinet needs 600 mm of clearance on all sides for service access and ventilation—critical in offshore nacelles where heat buildup risks performance loss. Grid connections must adhere to ABB’s recommended impedance limits (≤0.5 Ω) to minimize total harmonic distortion (THD <5%, per IEC 61000-3-6).

For long-term reliability, perform quarterly checks of cooling system filters and pressure (leaks can reduce efficiency by 10%+). Annual firmware updates—delivered via ABB’s remote portal—ensure compliance with evolving grid codes (e.g., EU’s Clean Energy Package). The ABB PCS6000’s built-in diagnostics track key metrics (IGCT temperature, power factor) and send alerts for proactive repairs, reducing unplanned downtime by 35% on average. In corrosive environments, apply ABB’s anti-corrosion cabinet coating to extend service life by 2+ years.

Warranty & Support Coverage

ABB stands behind the ABB PCS6000 with a 5-year standard warranty—among the longest in the industry—covering materials, workmanship, and performance under normal operating conditions. This warranty reflects ABB’s confidence in the converter’s long-term reliability for 20+ year wind farm lifecycles. Customers gain access to ABB’s global support network: 24/7 remote diagnostics via the ABB Ability™ platform, on-site service from certified engineers, and instant access to technical documentation (installation guides, FMEA reports, compliance certificates).

For mission-critical projects, ABB offers tailored service agreements—including predictive maintenance powered by AI analytics. A Middle Eastern wind farm using this program reduced unscheduled downtime by 40% by addressing cooling system issues before failures occurred. Spare parts are stocked in 20+ global distribution centers, ensuring 48-hour delivery to most regions. With this combination of coverage and support, the ABB PCS6000 delivers the customer assurance industrial and renewable energy operators demand.

Reviews

There are no reviews yet.