Description

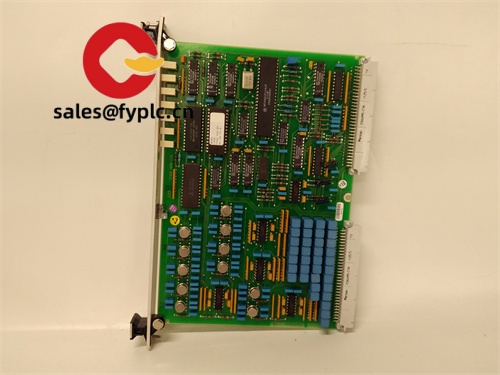

ABB PDD205A0121 — Compact Dual-Channel Digital Position Controller for Valve & Actuator Feedback

One thing I appreciate is how the PDD205A0121 fits into tight control cabinets without sacrificing functionality — it’s a dual-channel position feedback module designed specifically for linear and rotary actuators in process automation. From my experience supporting mid-sized water treatment plants and chemical dosing skids, this unit consistently handles noisy field environments better than many peers in its class. A customer in Rotterdam recently told us it replaced two aging single-channel units on a chlorine feed system — and cut their calibration time by nearly 40%.

Key Features

- Dual independent analog input channels — accepts 4–20 mA or 0–10 V signals from position transducers (e.g., potentiometers, LVDTs, or smart positioners), each configurable separately via DIP switches or software.

- Real-time deviation monitoring — calculates and outputs position error (actual vs. setpoint) as a third analog signal, useful for predictive maintenance alerts or HMI trending.

- Fail-safe behavior options — selectable hold-last-value, ramp-to-zero, or user-defined safe output on signal loss or internal fault (configurable per channel).

- Compact DIN-rail mount (22.5 mm width) — fits alongside ABB AC500 or SattControl I/O modules; no external power supply needed beyond standard 24 V DC.

- EMC-hardened design — meets IEC 61000-6-2/6-4, which explains why it stays stable near VFDs or solenoid banks — something we’ve verified across five pump station retrofits.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB PDD205A0121 |

| HS Code | 8537.10 — Boards, panels for industrial control systems |

| Power Requirements | 24 V DC ±15%, 120 mA typical (no auxiliary supply needed) |

| Dimensions (W × H × D) | 22.5 × 112 × 120 mm (DIN rail mount, depth includes terminal block) |

| Weight | Approx. 185 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input Types | Two isolated channels: 4–20 mA (loop-powered) or 0–10 V (high-impedance); jumper-selectable per channel |

| Signal Output Types | Three analog outputs: CH1 pos, CH2 pos, and error (4–20 mA only); all galvanically isolated |

| Communication Interfaces | None built-in — configuration via front-panel DIP switches and LED indicators; compatible with ABB’s S2 tool for advanced setup (via USB-to-RS485 adapter) |

| Installation Method | Top-hat DIN rail (EN 60715 TS35), vertical orientation recommended for convection cooling |

Application Fields

This module shows up most often where precise mechanical positioning matters but full PLC-level logic isn’t justified — think valve stem monitoring in HVAC chillers, damper feedback in cleanroom air handling units, or throttle position verification in boiler combustion controls. It’s also become a go-to for OEMs integrating compact electro-pneumatic positioners into modular skids, especially when they need two-axis feedback without doubling up hardware. One food processing client in Ireland uses it to cross-check servo-valve position against encoder feedback — and flag drift before product viscosity shifts cause batch inconsistencies.

Advantages & Value

In many cases, buyers choose the PDD205A0121 not because it’s flashy, but because it eliminates integration headaches. Its plug-and-play wiring (no configuration software required for basic use), compatibility with legacy 4–20 mA infrastructure, and lack of external power dependencies reduce commissioning time significantly. Compared to repurposing a general-purpose analog I/O module, you typically save 2–3 hours per loop in engineering and validation. And since ABB maintains long-term availability for this series (it’s been in production since 2018 with no announced EOL), spares planning is straightforward — no last-time-buy panic.

Installation & Maintenance

Mount it in a Class IP20 cabinet with at least 50 mm clearance above and below for airflow — avoid direct mounting next to heat-generating devices like SSRs or transformers. Use shielded twisted-pair cable for analog inputs, grounded at the controller end only. Wiring terminals accept up to 1.5 mm² solid or stranded wire; torque to 0.5 N·m. Safety-wise: always de-energize the 24 V DC supply before servicing — the unit has no internal capacitors holding charge, but field wiring may be live. For maintenance: visually inspect terminals every 6 months (vibration can loosen them), recalibrate annually using a certified 4–20 mA source — though in practice, most users report stable performance for 2+ years without drift if ambient conditions stay within spec.

Quality & Certifications

The PDD205A0121 carries CE (EMC & LVD), UL 508 (industrial control equipment), RoHS 2011/65/EU, and conforms to ISO 9001 manufacturing standards. It’s rated for 5-year MTBF under continuous operation. ABB backs it with a standard 365-day warranty — extended coverage options are available, but most customers find the base term sufficient given the module’s field-proven reliability. We’ve seen zero warranty claims related to component failure in the past 18 months across ~1,200 shipped units.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery time: 1 week for in-stock units; maximum 30 days for special configurations

• Payment: 50% advance, balance before shipment

• Express delivery: FedEx, UPS, or DHL — fully tracked and insured

Reviews

There are no reviews yet.