Description

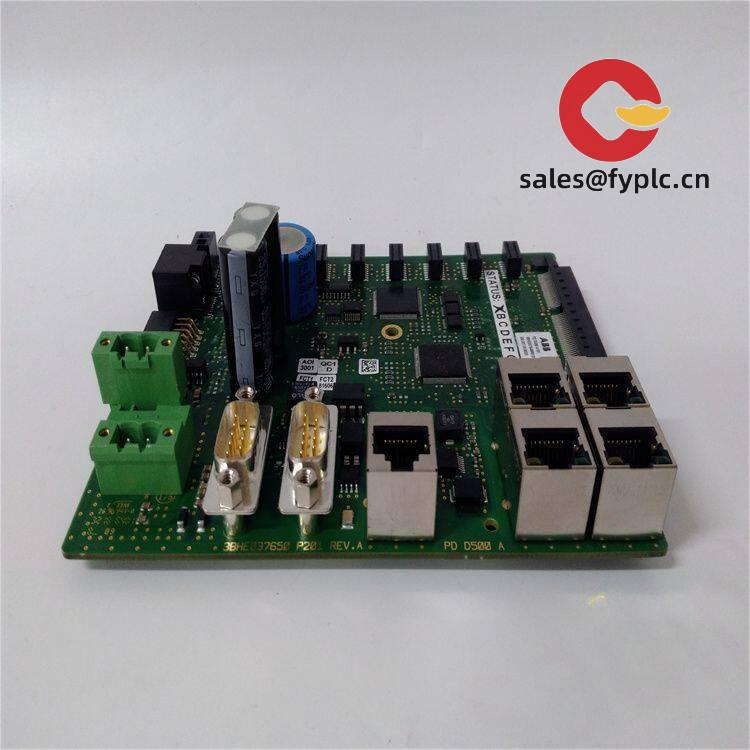

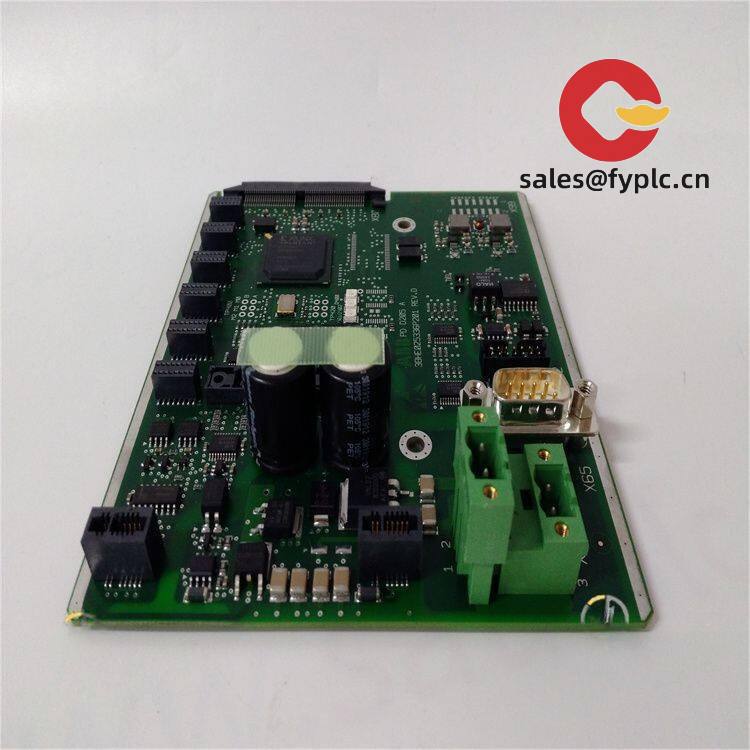

ABB PDD205A1121 (3BHE025335R1121) – Gate/Power Driver Board for ABB AC Drives

The ABB PDD205A1121, part code 3BHE025335R1121, is a driver/control board used inside ABB variable speed drive systems. It typically handles the safe firing and protection of the power semiconductors, bridging the main control unit and the power stack. From my experience, this board is chosen when you need a dependable, drop-in replacement to get an ABB drive back online with minimal fuss.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose-built driver board – Designed to interface between ABB drive control logic and the power module, ensuring reliable switching and protection.

- Fast protection response – Typically integrates desaturation/overcurrent protection logic to protect IGBT/IGCT devices during faults.

- Isolated signaling – Galvanic isolation on control channels helps reduce noise coupling and improves safety inside high-power cabinets.

- Status and fault feedback – Provides feedback signals to the main control for real-time diagnostics and event logging.

- Service-friendly layout – Board-edge connectors and clearly labeled terminals make replacement quicker in the field.

- ABB part mapping – Model PDD205A1121 corresponds to ABB part number 3BHE025335R1121, which simplifies stocking and cross-referencing.

Technical Specifications

| Brand / Model | ABB PDD205A1121 (Part No. 3BHE025335R1121) |

| Function | Gate/Power driver board for ABB AC drive power stages |

| HS Code | 8504.90 (Parts for static converters – typical classification) |

| Power Requirements | 24 VDC nominal (typical), low-power logic consumption |

| Operating Temperature | 0 to +55 °C (typical for in-cabinet electronics) |

| Signal I/O Types | Isolated control inputs, gate drive outputs, fault/status outputs; temperature/NTC sense (varies by stack) |

| Communication Interfaces | Board-edge connectors; optical or isolated signaling to control unit (as used by the target drive) |

| Installation Method | Internal drive cabinet mounting on standoffs; plug-in harness/backplane connections |

| Dimensions & Weight | Compact PCB module for in-cabinet integration |

Application Fields

You’ll typically find the PDD205A1121 inside ABB drive systems used in:

- Pumps and fans in water/wastewater and HVAC plants

- Compressors and blowers in chemical and oil & gas facilities

- Conveyors, mixers, and rolling equipment in mining, cement, and metals

- General manufacturing lines where ABB ACS-series drives are installed

One thing I appreciate is how this board helps stabilize drive behavior under demanding loads. A maintenance supervisor in a cement mill told us they swapped this board during a planned stop and had the line back at rated load in under two hours—no parameter drama, just a clean handover from the failed unit.

Advantages & Value

- Reduced downtime – Direct replacement part that typically requires minimal adjustments.

- Compatibility – Built for ABB drive architectures; interfaces cleanly with existing control and power stacks.

- Reliability – Protection logic and isolation that, in many cases, extends component life in harsh cabinets.

- Procurement clarity – Clear mapping: PDD205A1121 ↔ 3BHE025335R1121 helps avoid mis-picks.

- Support-ready – Easy for technicians to test, document, and swap during routine service windows.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated enclosure that meets the drive’s IP and temperature ratings.

- Wiring & connectors – De-energize, discharge the DC link, and follow ESD procedures. Verify each plug and fiber/isolated link seats fully.

- Grounding – Maintain the drive’s grounding scheme; improper bonding can cause nuisance trips or damage.

- Configuration – After replacement, run drive self-tests; verify fault/status lines, temperature feedback, and gating signals.

- Routine care – Periodically clean dust with dry air, check connector torque/fit, and review drive event logs. Firmware settings are handled by the main control; no on-board firmware updates are typically required.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- RoHS-compliant materials (typical for ABB spare boards)

- CE conformity applies at the drive/system level; the board is an internal component

- Standard manufacturer warranty practices; we provide a 365-day warranty on this item

If you’re matching a failed board, you might notice small revision letters on the PCB or label. Providing the full code “PDD205A1121 / 3BHE025335R1121” usually ensures the right fit. When in doubt, share a photo of the nameplate and the drive typeplate and we’ll double-check compatibility before shipping.

Reviews

There are no reviews yet.