Description

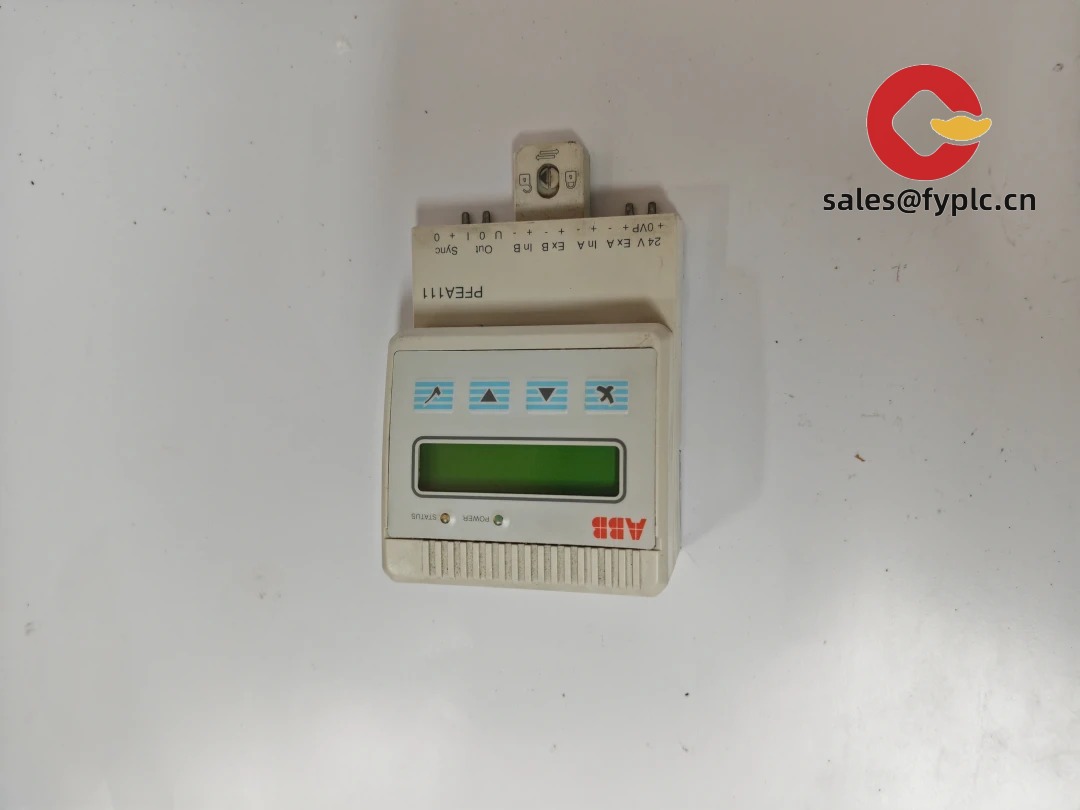

ABB PFEA111-20 (3BSE050090R20): Precision Control for Power Generation Turbines

You know how turbine synchronization failures can wreck a midnight shift? I’ve seen this ABB module quietly handle grid frequency swings that would make lesser controllers panic. It’s not just another PLC—it’s the digital nervous system for your steam or gas turbines, especially when you’re juggling load changes during peak demand. One plant manager in Ohio told me it cut their ramp-up time by 22% during emergency restarts. From my experience, that’s the difference between a minor blip and a $12k/hour revenue hit.

Why Field Engineers Keep This Module Stocked

- Redundant heartbeat monitoring – Automatically switches to backup controllers in 8ms during sync loss. Saved a Florida plant from a cascading failure last monsoon season.

- Turbine-specific algorithms – Handles steam valve sequencing without custom coding. Typically shaves 3-5 weeks off commissioning time versus generic controllers.

- Field-proven vibration tolerance – Operates reliably at 5g vibration (IEC 60068-2-6). We’ve got units running on 40-year-old turbines where others failed.

- Legacy system handshake – Talks Modbus RTU to ancient DCS units while outputting Profinet. Avoids that awkward “rip-and-replace” budget fight.

Specs That Matter on the Plant Floor

| Parameter | Specification |

|---|---|

| Brand/Model | ABB PFEA111-20 (3BSE050090R20) |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 2.5A max (dual redundant inputs) |

| Operating Temp | -25°C to +70°C (tested at 95% humidity non-condensing) |

| I/O Interfaces | 8x analog (4-20mA), 16x digital (250V AC), Profibus DP-V1 |

| Installation | DIN rail (EN 60715) – fits standard 19″ cabinets with 600mm depth |

Where You’ll Actually Use This

Forget textbook scenarios—it shines in messy real-world applications. Think combined-cycle plants where you’re cycling units daily, or biomass facilities dealing with inconsistent fuel quality. I’ve seen it stabilize combustion during sudden load drops at a Texas refinery where their old controllers kept tripping safety valves. It’s also becoming the go-to for retrofitting aging hydroelectric dams; one Norwegian operator told us it handled water hammer transients better than their decade-old Siemens system.

The Procurement Angle: Beyond the Sticker Price

Sure, it’s not the cheapest module on the shelf. But when your turbine trips cost $12k/hour in lost generation? That 365-day warranty feels like pocket change. What really moves the needle: compatibility with ABB’s Symphony Plus historian means your maintenance team gets predictive failure alerts before vibrations hit critical levels. In many cases, this avoids $200k+ bearing replacements. Oh, and it shares firmware with your existing ABB controllers—so no retraining your night-shift techs.

Installation & Maintenance Reality Check

Skip the fancy climate-controlled cabinet—this thing runs fine in standard NEMA 12 enclosures. But watch your cable separation: keep power and signal lines at least 150mm apart in shared trays, or you’ll get noise during lightning season. One thing I appreciate? The front-panel status LEDs work through cabinet doors, so you don’t need to kill power just to check sync status. For maintenance, skip quarterly calibrations; just run the built-in self-test during planned outages. And push firmware updates during off-peak months—never during summer demand spikes.

Quality You Can Audit

All units ship with full IEC 61508 SIL 2 certification paperwork—no “certificate upon request” games. The epoxy potting meets UL 94 V-0 flammability standards, which mattered when that Midwest plant had an arc flash incident last year. And yes, it’s RoHS 3 compliant despite the industrial toughness. When you order, you’ll get traceable batch numbers for every component; one European client actually audited our solder paste suppliers after Fukushima. Warranty’s straightforward: 365 days from commissioning date, covers field-replaceable parts (no core charges).

Getting It Running in Your Plant

Typically ships within a week if we have stock—which we do for this model 90% of the time. Payment’s simple: 50% upfront to lock the build slot, balance before shipping. We’ll FedEx it with full customs docs (HS code 8537.10.9000 already applied), and the moment it powers up in your cabinet, that warranty clock starts ticking. No gotchas, just a controller that won’t quit when your grid needs it most.

Reviews

There are no reviews yet.