Description

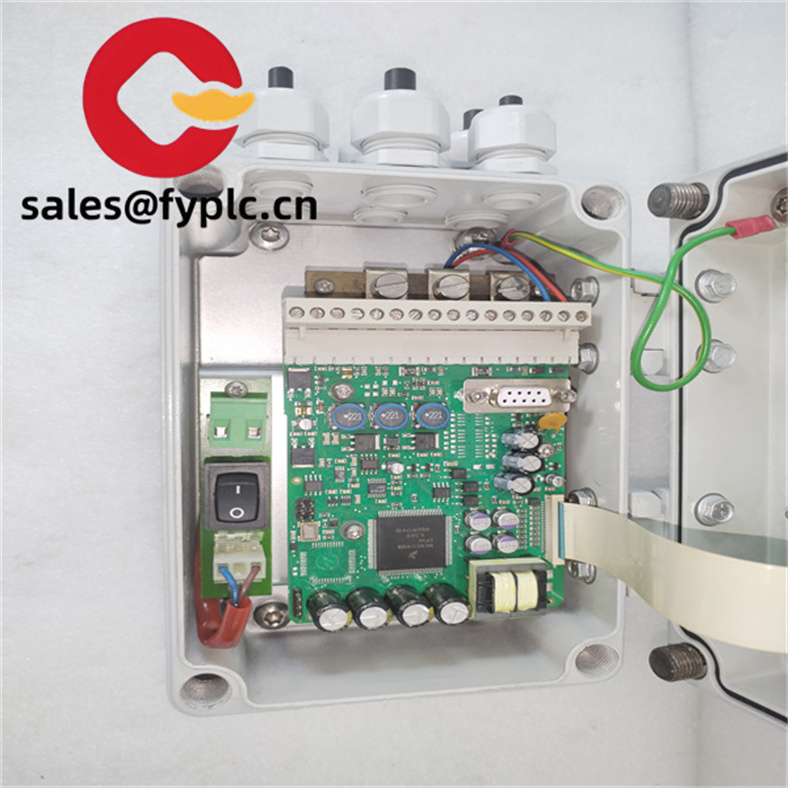

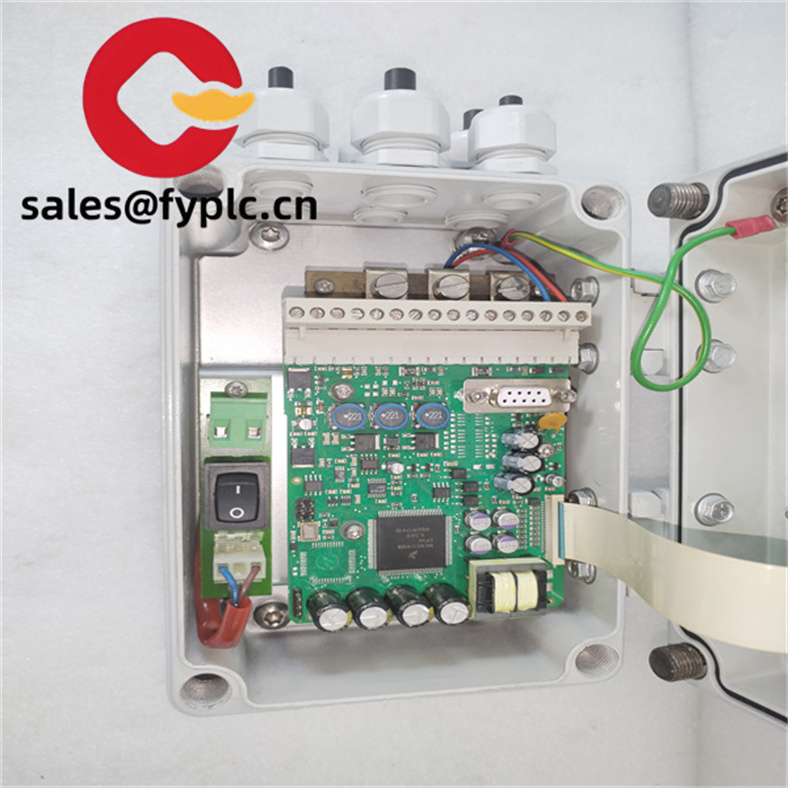

ABB PFEA112-65 Tension Controller Servo Module

In the dynamic and complex world of industrial automation, the PFEA112-65 by ABB emerges as a versatile and high-performance control module, engineered to be the backbone of numerous industrial control systems. ABB, a global titan in power and automation technologies, has designed this module to address the intricate demands of modern industrial operations, ensuring seamless data processing, reliable communication, and precise control across diverse applications.

The PFEA112-65 is a sophisticated programmable control unit that plays a crucial role in industrial automation setups. Its core purpose is to act as the central nervous system of a control system, receiving inputs from various sensors that monitor key parameters like temperature, pressure, speed, and position within industrial processes. By analyzing these inputs with remarkable speed and accuracy, the module generates appropriate control signals to actuators, motors, and other equipment, enabling the fine-tuning of operations. Whether integrated into a high-speed manufacturing line, a power generation facility, or a chemical processing plant, the PFEA112-65 ensures that processes run smoothly, efficiently, and within the desired operational boundaries, enhancing productivity while maintaining safety and quality standards.

| Label |

Specification |

| Model Number |

PFEA112-65 |

| Brand |

ABB |

| Type |

Programmable Control Module |

| Input Voltage |

24V DC |

| Operating Temp |

-20°C – 60°C |

| Communication Method |

Ethernet, Profibus DP, Modbus RTU |

| Mounting |

DIN-rail mountable |

| Weight |

Around 0.7 kg |

| Certifications |

CE, UL, IEC 61131 – 2 |

| Dimensions |

125mm x 85mm x 45mm (H x W x D) |

The PFEA112-65 is packed with functional strengths and design advantages that make it a standout in real-world industrial environments. One of its most notable features is its high-speed processing power. In fast-paced industrial operations where split-second decisions can make a significant difference, this module can handle complex algorithms and large volumes of data instantaneously. For example, in a food processing plant with a high-speed packaging line, the PFEA112-65 can quickly analyze sensor data related to product positioning and packaging material flow, and then send precise control signals to robotic arms and conveyors to ensure seamless packaging, reducing errors and increasing output.

Reliability is at the core of the PFEA112-65‘s design. Constructed with top-notch components and a rugged build, it can withstand the harsh conditions typical of industrial settings, including electrical noise, vibrations, and extreme temperature fluctuations. Its advanced electrical isolation and shielding mechanisms protect against interference, ensuring the integrity of data and control signals. This resilience means that the module can operate continuously with minimal maintenance, reducing downtime and saving costs for industrial operators.

Interoperability is another key strength of the PFEA112-65. It supports multiple industrial communication protocols, allowing it to integrate effortlessly with a wide range of devices and systems, regardless of the manufacturer. This flexibility enables easy expansion and upgrading of existing automation setups. For instance, when a factory decides to incorporate new IoT-enabled sensors or upgrade its control software, the PFEA112-65 can adapt without major compatibility issues, making it a future-proof solution for evolving industrial needs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.