Description

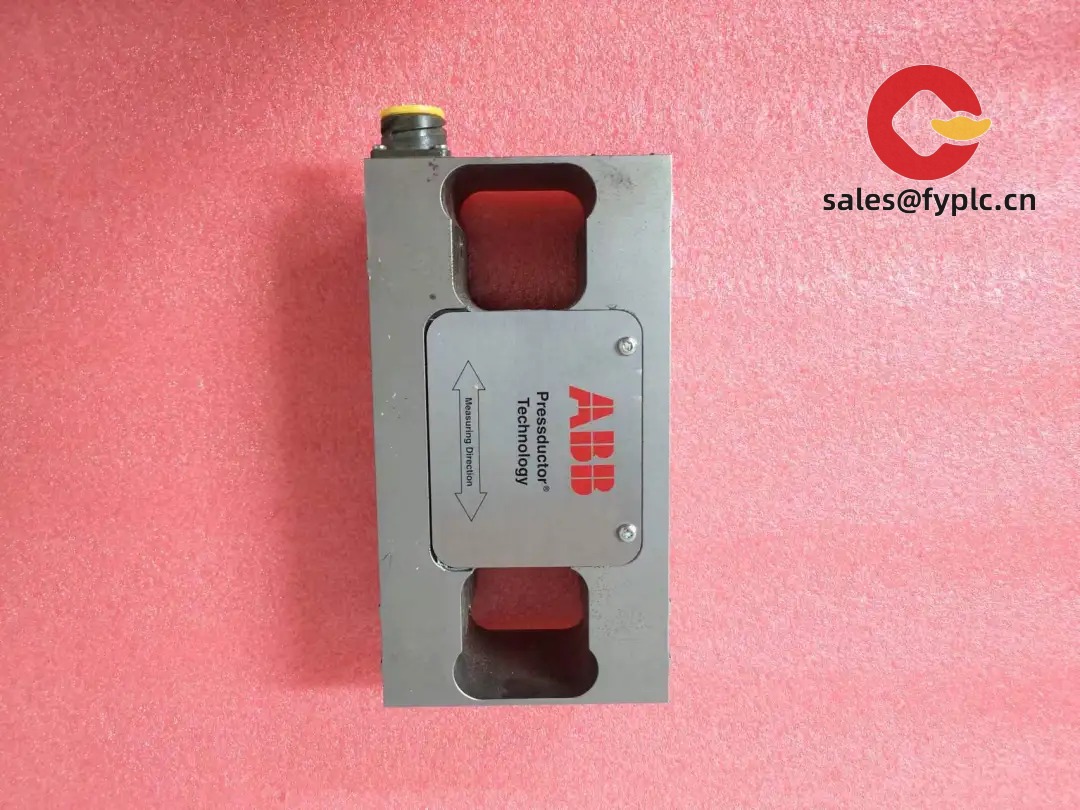

ABB PFTL101A-2.0KN (3BSE004172R1) – Pressductor Tension Load Cell for Web/Strip Force Measurement

The ABB PFTL101A-2.0KN is a Pressductor force transducer designed to measure web and strip tension with high stability in demanding lines—paper, film, metal strip, wire drawing, and converting are typical examples. One thing I appreciate is how this magnetoelastic sensor remains dependable where strain-gauge load cells struggle—temperature swings, side forces, or shock loads. It’s usually paired with ABB PFEA tension electronics to deliver clean, usable signals (4–20 mA, 0–10 V, or fieldbus via the electronics).

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Pressductor magnetoelastic principle – Typically superior stability and low drift in hot, humid, or vibration-prone environments.

- 2.0 kN nominal capacity – Suits light to medium web/strip tensions on paper, film, foil, and narrow metal lines.

- Robust against side loads – In many cases, less sensitive to misalignment or lateral forces than conventional strain-gauge cells.

- Pairs with ABB PFEA electronics – Clean setup with ABB PFEA 111/112/113 for analog or fieldbus outputs.

- Industrial-grade sealing – Typically IP-rated housing for mill-duty service and washdown zones.

- Stable over time – From my experience, Pressductor cells reduce recalibration frequency on continuous process lines.

Technical Specifications

| Brand / Model | ABB PFTL101A-2.0KN (Part No. 3BSE004172R1) |

| Measurement Principle | Pressductor magnetoelastic force transducer (passive two-coil design) |

| Nominal Measuring Range | 2.0 kN (2000 N) |

| HS Code (reference) | 9031.80 (Measuring/Checking Instruments, other) |

| Power Requirements | Passive sensor; excitation and signal conditioning provided by ABB PFEA tension electronics |

| Operating Temperature | Typically −10 to +60 °C (application dependent) |

| Ingress Protection | Industrial IP rating (commonly IP67 for PFTL series) |

| Signal I/O (Sensor) | Two-coil (4-wire) transducer connection to PFEA electronics |

| Communication Interfaces | Via paired electronics (e.g., 0/4–20 mA, 0–10 V, Profibus/DP, Profinet, or Ethernet/IP depending on PFEA module) |

| Installation Method | Bolted to machine frame/bearing support; typically used under an idler roll bearing block |

| Housing | Corrosion-resistant steel body, mill-duty construction |

| Dimensions & Weight | Varies by sub-variant; the 2.0 kN model is compact and typically a few kilograms (confirm against ABB drawing for 3BSE004172R1) |

Application Fields

This model is commonly installed on web-handling lines where accurate tension is crucial:

- Paper machines and coaters – steady draw control through press and dryer sections.

- Plastic film/foil extrusion and slitting – tight tolerance winding and slitting tension.

- Metallurgical strip processing – annealing, galvanizing, leveling, and recoiling lines.

- Textile and nonwovens – consistent web tension for quality surface finish.

- Wire and cable lines – dancer and payoff/load feedback for constant pull.

You might notice that in retrofit projects, PFTL101A often drops into existing frames with minimal machining, especially where ABB electronics are already on site.

Advantages & Value

- Reliability – The Pressductor core is inherently rugged; in many cases it tolerates shock and side loads better than foil strain gauges.

- Compatibility – Pairs natively with ABB PFEA 111/112/113, which simplifies wiring and scaling across multiple stands.

- Cost control – Fewer re-calibration calls and high uptime typically offset the initial sensor cost in continuous-process plants.

- Supportability – Mature ABB platform with established spares and field know‑how.

A maintenance lead at a foil coater told us the swap from mixed-brand load cells to PFTL101A + PFEA cut their “nuisance drift checks” by half—seems to be the magnetoelastic stability paying off.

Installation & Maintenance

- Mounting – Bolt to a rigid frame/bearing block. Keep the force line centered. Avoid soft shims that introduce compliance.

- Cabinet & wiring – Install PFEA electronics in a ventilated cabinet (IEC-standard enclosure). Use shielded 4‑wire cabling from sensor to electronics; ground per ABB guidelines.

- Environment – Protect connectors from coolant and paper dust; maintain drip loops and strain relief on the cable.

- Safety – De-energize drives, lockout/tagout rotating rolls, and ensure mechanical supports before mounting/removal.

- Routine checks – Verify bolt torque, inspect cable/connector integrity, and confirm zero/span in the PFEA annually (or after major mechanical work).

- Calibration – Use test weights or built-in electronics calibration functions; document as‑found/as‑left values for audits.

- Firmware – Keep the PFEA firmware current for filtering and diagnostics improvements.

Quality & Certifications

- CE conformity (typical for ABB force measurement products)

- RoHS compliance

- Manufactured under ISO 9001 quality systems

- Manufacturer warranty commonly available; we provide 365-day warranty on supply

Note: For final mounting dimensions, connector pinout, and exact IP class of the PFTL101A-2.0KN variant (3BSE004172R1), we recommend confirming against the ABB datasheet or drawing for your roll geometry. We can help verify compatibility with your existing PFEA setup before you place the order.

Reviews

There are no reviews yet.