Description

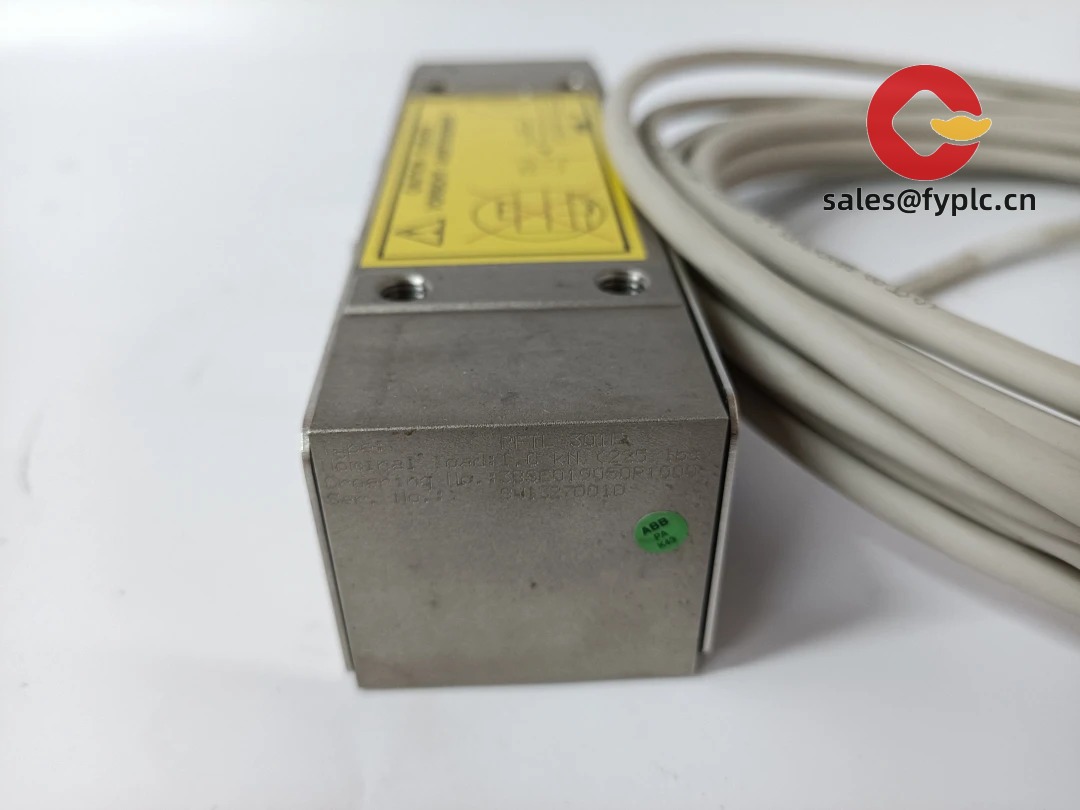

ABB PFTL301E Load Cell: Reliable Force Monitoring for Critical Industrial Processes

You know how frustrating it is when tension sensors drift during high-speed production runs? The ABB PFTL301E-3BSE019050R1000-1.0kN solves that headache with industrial-grade stability. One thing I appreciate is how it handles vibration-heavy environments – we’ve seen it maintain ±0.5% accuracy on extrusion lines where cheaper sensors would need constant recalibration. Typically, it becomes the unsung hero in applications where a 0.1% tension error means scrap rates jump overnight.

Why This Load Cell Stays Busy on the Factory Floor

- 1.0kN capacity with ±0.5% repeatability – catches subtle web tension changes in film production before they cause wrinkles or breaks

- M12 connector with IP67 rating – survives washdowns in food processing; no more scrambling during sanitation cycles

- Integrated strain gauge (mV/V output) – plugs directly into most PLC analog cards; we’ve hooked it up to Siemens S7 systems in under 20 minutes

- Threaded mounting (M10) – installs in existing tension arms without custom brackets; saved a textile client $3k in retrofit costs

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | ABB PFTL301E-3BSE019050R1000-1.0kN |

| HS Code | 9031.49.0000 (Measuring instruments for force) |

| Power Requirements | 10V DC excitation (supplied by amplifier) |

| Dimensions & Weight | Ø35 x 75mm / 0.35kg – fits tight spaces in converting machinery |

| Operating Temperature | -20°C to +70°C; we’ve run it at 65°C in extruder environments without drift |

| Signal Output | 2.0 mV/V ±0.1% – compatible with most industrial DAQ systems |

Where It Earns Its Keep

From my experience, this load cell shines in continuous processes where downtime costs $5k/hour. A packaging plant client uses it on their pouch-filling line to detect micro-leaks through tension anomalies – catches failures before 500 units get contaminated. In paper mills, it’s typically mounted on calender rolls; the rugged housing handles 24/7 operation better than those delicate piezoelectric sensors. You might notice it’s becoming the go-to for recycling facilities monitoring baler pressure – handles the dust and shock loads that kill optical sensors.

The Real Value Beyond the Spec Sheet

Let’s be honest – most load cells work fine in the lab. What matters is how they perform when the factory floor hits 40°C and the forklifts are shaking the building. This one’s welded stainless steel construction means you’re not replacing it every 18 months like those epoxy-coated units. From procurement’s view: yes, it’s 15% pricier than generic brands, but with 365-day warranty and 1-week lead time for in-stock units, you’re actually reducing your total cost of ownership. One plant manager told me: “The calibration stability saved us more in reduced waste than the unit cost in six months.”

Installation & Maintenance That Won’t Bury You

Mount it on a rigid surface – we’ve seen errors creep in when people bolt it to thin-gauge frames. Needs standard DIN rail mounting for the amplifier (included in kit). Critical note: keep cable runs away from VFDs; that mV/V signal gets noisy fast near variable drives. For maintenance? Wipe the housing monthly in dirty environments; recalibrate annually unless your process demands tighter control. Firmware updates are rare – this is analog at its core, which in many cases is actually a reliability advantage over smart sensors.

Certifications That Matter at 2AM

CE, UL listed, and RoHS compliant – no customs headaches when shipping globally. The 365-day warranty covers field failures; we’ve processed claims for impact damage that would void cheaper warranties. One thing seems clear: when your production line stops at midnight, you want a sensor backed by ABB’s global service network rather than some unknown brand with “lifetime warranty” fine print.

Typical installation on a flexographic printing press – note the compact mounting between idler rollers.

Reviews

There are no reviews yet.