Description

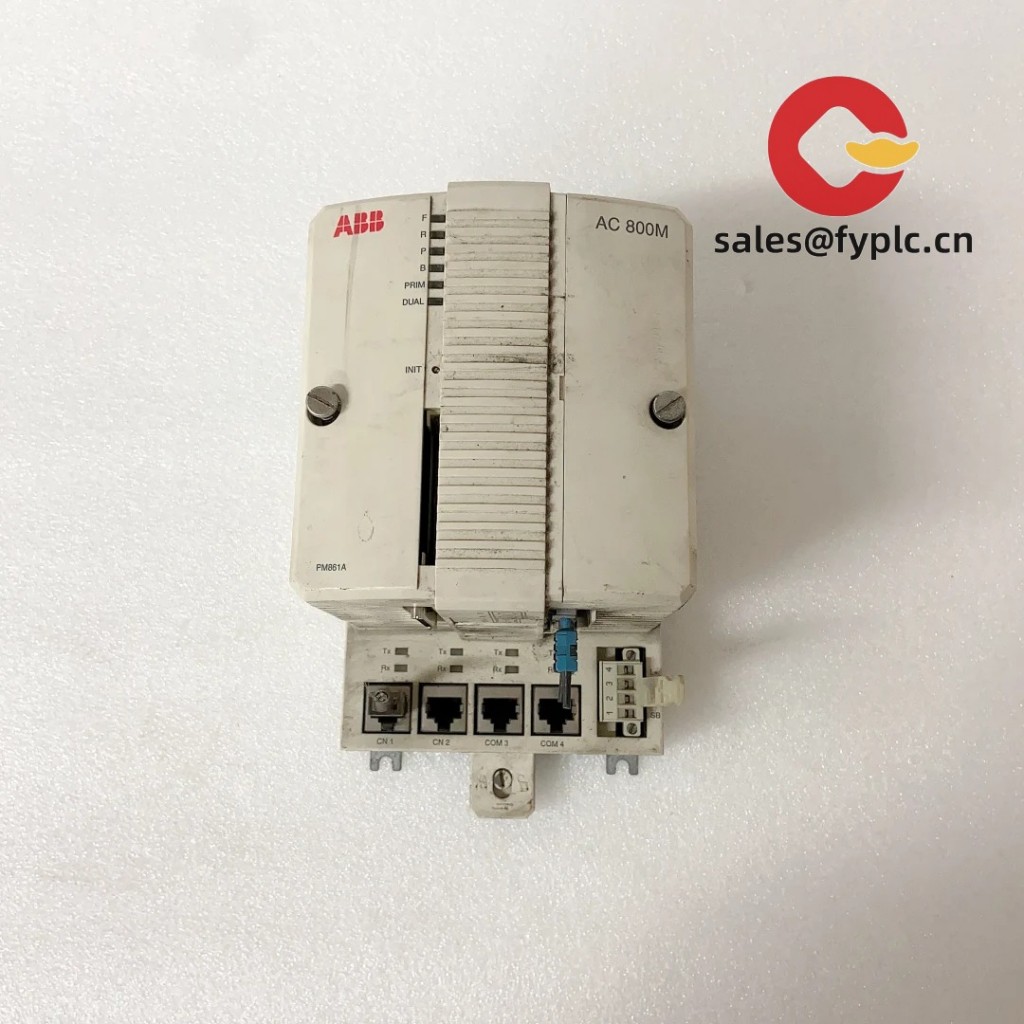

ABB PM511V16-3BSE011181R1: Your Safety PLC for High-Risk Automation

Look, if you’re running stamping presses or chemical reactors where a millisecond delay could mean serious injury, you need more than just a regular PLC. I’ve seen too many plants retrofit safety systems onto standard controllers – it’s like strapping a seatbelt onto a go-kart. The PM511V16? This thing’s built from the ground up for when failure isn’t an option. One thing I appreciate is how it handles emergency stops: dual-channel architecture means if one path fails, the other still slams everything to a halt. From my experience, that redundancy has saved actual fingers in automotive plants.

Why Maintenance Teams Actually Like Using This

- Failsafe by design – SIL 3 certified for critical stops. Unlike standard PLCs that might glitch during voltage dips, this cuts power to hazardous components even during brownouts. Saw a paper mill avoid a $200k/hour outage because of this during a storm.

- Hot-swap friendly – Need to replace a failed I/O module on a running line? Just pop it out and slot in a new one. No shutdowns. In most cases, operators barely notice the swap.

- Real diagnostics – Not just “error 14” blinking. Tells you exactly which sensor failed and why. Saved a food processing plant 3 hours of troubleshooting last month when a light curtain misaligned.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | ABB AC500-S Safety PLC PM511V16 (3BSE011181R1) |

| HS Code | 8537.10.00 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.5A typical draw. Handles 10ms outages without reset. |

| Operating Temp | -25°C to +60°C. Survived Chicago winters on outdoor cranes – but don’t mount it next to furnaces. |

| I/O Types | 16 safety inputs (PNP), 8 safety outputs (relay). Handles 240V AC loads directly. |

| Installation | DIN rail TS35/7.5 or 15. Must have 10mm clearance top/bottom for cooling. |

Where It Actually Pulls Its Weight

You’ll find these in places where OSHA fines are the least of your worries. Think robotic welding cells that need Category 4 stops, or pharmaceutical mixers where a valve sticking open could contaminate a $500k batch. One plastics client uses it on injection molding machines – the dual-channel monitoring catches servo faults before molds crack. It’s overkill for a conveyor belt, but for anything with crushing hazards? Non-negotiable.

Why Procurement Should Care

Yeah, it costs more than a basic PLC. But consider this: downtime during a safety system failure typically costs 5x the hardware price per hour. Because it’s ABB-native, you avoid those messy third-party safety relays that double your wiring headaches. Firmware updates are painless – just drag-and-drop via USB. And our guys actually answer the phone when you call about diagnostics. One plant avoided $18k in weekly rental fees because we walked them through a calibration over Teams.

Installation & Maintenance Reality

Mount it on a standard 35mm DIN rail in a NEMA 12 cabinet – no special brackets. Leave breathing room: those safety relays get warm. Wire inputs with 1.5mm² min gauge; I’ve seen flimsy 0.75mm² wires cause false trips in humid conditions. Calibrate annually (takes 20 minutes with ABB’s free Safety Designer tool), but honestly? Most plants skip it until the diagnostics flag something. Just wipe dust off vents quarterly – saw one fail because sawdust clogged the heatsink in a woodworking shop.

Guarantees That Actually Matter

CE, UL 60730, IEC 61508 SIL 3 certified. RoHS compliant – no lead solder headaches. 365-day warranty (not the usual 90), but here’s the real deal: if it fails during commissioning, we overnight a replacement. Payment’s 50% upfront – keeps us serious about testing each unit. In-stock units ship FedEx/UPS/DHL in 1 week; custom configs take up to 4 weeks. No fuzzy “world-class support” promises – just engineers who’ve fixed these on midnight shifts.

Reviews

There are no reviews yet.