Description

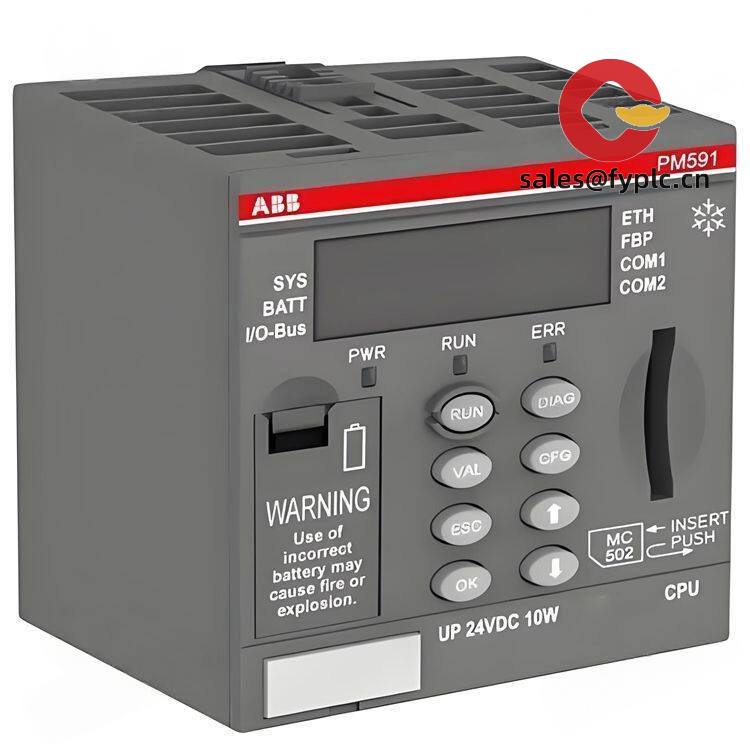

ABB PM592-ETH (1SAP150200R0271) – High‑performance AC500 PLC CPU with integrated Ethernet for fast control and easy networking

The ABB PM592-ETH is a robust CPU module for the AC500 platform, designed for demanding machine and process control where stable cycle times and reliable Ethernet connectivity are non‑negotiable. It slots into standard AC500 architectures, drives S500 I/O over the backplane, and typically serves as the central controller when you need deterministic logic, scalable communications, and long-term serviceability. One thing I appreciate is how straightforward it is to commission over the built‑in Ethernet, which in many cases cuts downtime during upgrades or format changes.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Integrated Ethernet (RJ45): Streamlines programming, HMI/SCADA links and controller‑to‑controller data exchange; typically supports standard TCP/IP services and Modbus TCP on the AC500 family.

- High‑performance AC500 CPU: PM592 offers faster processing for complex logic, motion coordination, or data handling compared to entry models in the series.

- Modular I/O expansion: No onboard I/O; pair with S500 I/O modules to match exact channel counts and signal types, so you don’t overpay for unused points.

- 24 V DC industrial power: Fits common control cabinet power architectures and simplifies redundancy setups.

- Rugged temperature range: Built for typical plant environments; from my experience, the AC500 handles heat and vibration well when installed per cabinet guidelines.

- SD card program handling (series feature): Facilitates backup/restore and faster rollouts across identical machines.

- DIN‑rail mounting: Fast installation in standard EN 60715 panels with tidy wiring and service access.

Technical Specifications

| Brand / Model | ABB PM592-ETH – Order Code: 1SAP150200R0271 (AC500 CPU module) |

| HS Code | 8537.10 (Programmable controllers; for a voltage ≤ 1000 V) |

| Power Requirements | 24 V DC nominal (industrial control cabinet supply) |

| Operating Temperature | -25 °C to +55 °C (typical for AC500 PM59x CPUs) |

| Communication Interfaces | 1 × Ethernet (RJ45, 10/100 Mbps); serial and fieldbus via optional AC500 communication modules |

| Signal I/O Types | No onboard I/O; expandable with S500 digital/analog I/O modules |

| Installation Method | DIN rail (EN 60715) inside IP20 control cabinet |

| Protection Rating | IP20 (control cabinet use) |

| Dimensions & Weight | Approx. 110 × 142 × 75 mm; ~0.6 kg (typical AC500 PM59x footprint) |

Application Fields

The PM592-ETH fits mid‑to‑high complexity automation such as packaging lines, material handling, metal forming, water/wastewater skids, and energy balance systems. You might notice that the built‑in Ethernet makes it simple to link to SCADA or an edge gateway for OEE dashboards, while S500 I/O lets you scale from a compact machine panel to a multi‑bay cabinet without changing the CPU concept.

- Machine building and packaging – fast logic, recipe handling, HMI over Ethernet

- Utilities and water – distributed I/O, Modbus TCP to drives and instruments

- Material handling – conveyor control, interlocks, line coordination

- Process skids – standardized PLC core with SD card program loading for replication

Advantages & Value

- Reliability: AC500 platforms are widely deployed; spares and firmware are stable and supported.

- Compatibility: Works seamlessly with S500 I/O, ABB drives, and common SCADA via Ethernet protocols.

- Cost control: Modular I/O prevents overspec; you only add what you need, when you need it.

- Lifecycle support: From my experience, ABB’s documentation and engineering tools reduce ramp‑up and maintenance hours.

Installation & Maintenance

- Cabinet & mounting: Install on EN 60715 DIN rail in an IP20 panel with adequate ventilation. Keep ambient within the specified temperature band.

- Power & grounding: Use a clean 24 V DC supply with proper grounding. Separate field power from logic power where possible.

- Wiring practice: Route Ethernet away from high‑noise VFD cables; use shielded twisted pair for long runs and bond shields correctly.

- Routine maintenance: Periodically back up the program to SD card or engineering PC, clean dust from vents, and review diagnostic logs. Plan firmware updates during scheduled downtime, not mid‑shift.

- Spare strategy: Keeping one spare CPU and a preloaded SD card typically cuts MTTR to minutes.

“We swapped a legacy PLC to PM592‑ETH and had the line back in production the same afternoon. Ethernet commissioning was the time saver.” — Maintenance Supervisor, beverage packaging (shared with permission)

Quality & Certifications

- Conformity: CE

- Safety: cULus (typical for AC500 family)

- Environmental: RoHS

- Manufacturer’s policy: standard warranty coverage applies; our supply warranty is 365 days

Reviews

There are no reviews yet.