Description

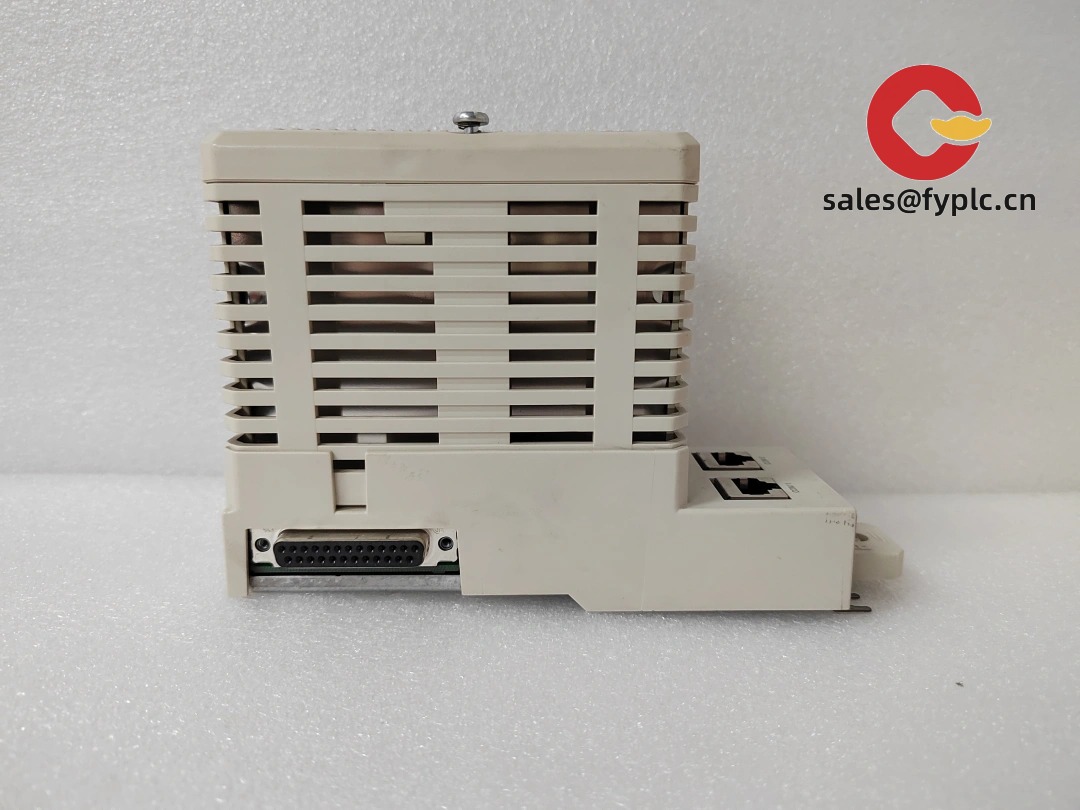

ABB PM820 – High-Performance Redundant Automation Controller for Critical Process Applications

The ABB PM820 isn’t just another PLC—it’s a modular, fault-tolerant automation controller built for environments where downtime isn’t an option. Think refinery safety interlocks, power plant boiler control, or continuous pharmaceutical batch systems. From my experience supporting mid-to-large-scale process projects, the PM820 stands out when you need deterministic execution, hot-swappable redundancy, and native integration with ABB’s 800xA DCS ecosystem—without forcing you into proprietary lock-in.

One thing I appreciate is how cleanly it bridges legacy fieldbus infrastructure (like Profibus DP or Modbus RTU) with modern Ethernet-based control layers. You might notice that unlike many entry-level controllers, the PM820 doesn’t require external gateways to talk to HART-enabled transmitters or Foundation Fieldbus segments—it handles those natively through optional interface modules.

Key Features

- Hot-standby redundancy — Dual CPU modules synchronize state in real time; failover typically occurs in under 50 ms, with no loss of I/O or active alarms.

- Modular I/O architecture — Supports up to 16 I/O modules per rack (including analog input/output, digital I/O, and specialty modules like thermocouple or pulse counting), all with channel-level diagnostics.

- Integrated safety logic — Certified to SIL 2 per IEC 61508 (TÜV-certified firmware), enabling safety shutdown functions without requiring a separate safety PLC in many cases.

- Native 800xA integration — Uses standard ABB AC 800M engineering tools (Control Builder M) and communicates over ABB’s proprietary AC 800M protocol as well as OPC UA and Modbus TCP.

- Extended environmental tolerance — Rated for operation from −25°C to +70°C, and tested for vibration resistance up to 5 g (10–500 Hz), making it suitable for offshore or mobile plant installations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB PM820 (standard configuration: dual CPU, 16-slot chassis) |

| HS Code | 8537.10.90 (Controllers for industrial processes, programmable, not elsewhere specified) |

| Power Requirements | 24 V DC (±20%), 12–20 A depending on I/O load; redundant power supply inputs supported |

| Dimensions & Weight | 483 × 315 × 210 mm (W × D × H); ~12.4 kg (fully loaded with 16 I/O modules) |

| Operating Temperature | −25°C to +70°C (derating applies above 55°C) |

| Signal Input/Output Types | Analog (4–20 mA, ±10 V, RTD, TC), Digital (24 V DC sinking/sourcing), Pulse, HART, FF H1 (via optional module) |

| Communication Interfaces | 2× Ethernet (100BASE-TX, configurable as ControlNet, Modbus TCP, or OPC UA); 2× RS-485 (Modbus RTU, Profibus DP master/slave); optional fiber optic expansion |

| Installation Method | Standard 19″ rack-mount (4U height); DIN rail mounting also supported via optional adapter kit |

Application Fields

The PM820 shows up most often where uptime, traceability, and regulatory compliance converge. In water treatment plants, it’s used for SCADA-integrated pump station control with built-in audit logging. In chemical manufacturing, customers rely on its deterministic scan cycle (as low as 5 ms) for reactor temperature ramping sequences. One client in Norway even deployed it on a floating LNG facility—where cabinet space is tight and vibration is constant—and reported zero unplanned reboots over 18 months. It’s less common in discrete assembly lines (where Allen-Bradley or Siemens S7-1500 dominate), but shines in continuous or hybrid process environments.

Advantages & Value

- Reduced integration risk — Pre-certified drivers for major field devices (Emerson DeltaV, Yokogawa CENTUM VP, Honeywell Experion) mean fewer custom OPC wrappers or protocol converters.

- Lower TCO over 5+ years — While upfront cost sits above basic PLCs, the extended service life (ABB quotes 15-year obsolescence horizon), long warranty, and minimal need for external safety hardware add up.

- Stronger support continuity — Unlike some OEMs that sunset platforms after 7 years, ABB maintains firmware updates and spare parts for the PM820 series well beyond typical industry norms—this seems to be part of their DCS-aligned roadmap.

- Procurement flexibility — We stock core configurations (CPU, power, base chassis), so delivery is typically within one week. For custom I/O mixes, lead time rarely exceeds four weeks—even with full SIL documentation packages.

Installation & Maintenance

Install in a NEMA 12 or IP54-rated cabinet with ≥200 mm clearance above and below for convection cooling—forced air isn’t required unless ambient exceeds 55°C. Wiring must follow IEC 61000-6-2 for EMC; shielded twisted-pair is mandatory for analog signals longer than 10 m. Grounding should be single-point, tied to the main system earth bar—not the cabinet frame.

For maintenance: verify firmware version every 6 months (ABB releases patches ~2x/year for security and stability); clean air filters quarterly if installed in dusty environments; calibrate analog inputs annually using certified reference sources. No routine battery replacement needed—the real-time clock is powered by supercapacitor, not lithium cells.

Quality & Certifications

The PM820 carries CE (EMC & LVD), UL 508A (Industrial Control Equipment), ATEX II 2G Ex db IIB T4 Gb (for Zone 1 hazardous areas), and IECEx certification. It’s RoHS 3 compliant and manufactured under ISO 9001:2015 and ISO 14001:2015. ABB provides a standard 365-day warranty covering parts and labor—extended coverage up to 5 years is available upon request, including remote diagnostics support.

Our order placement process: 50% advance payment secures build slot and expedites documentation; balance due before dispatch. In-stock units ship within 1 week via FedEx/UPS/DHL (tracking provided). Non-stock configurations ship within 4 weeks maximum—no exceptions. All units are pre-tested with loop-check reports included.

Reviews

There are no reviews yet.