Description

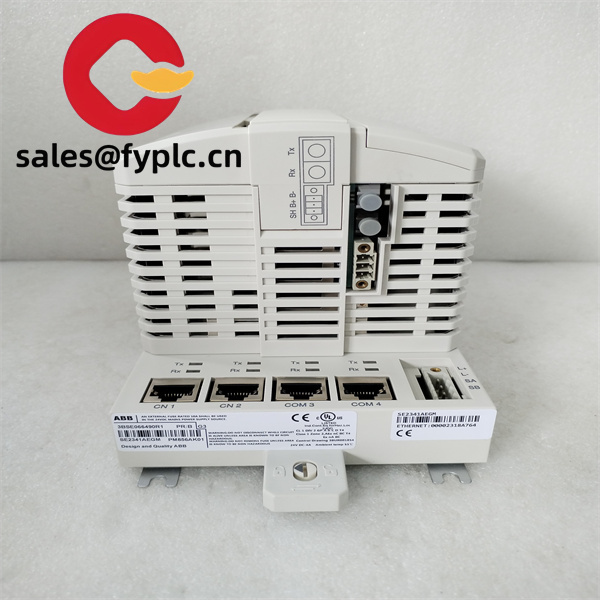

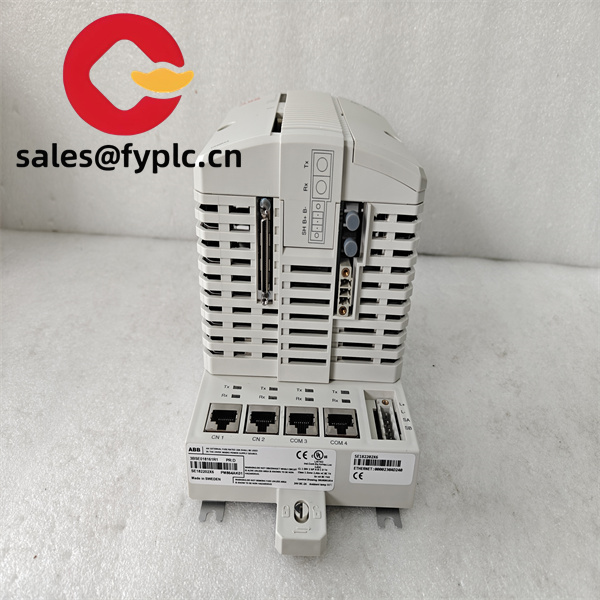

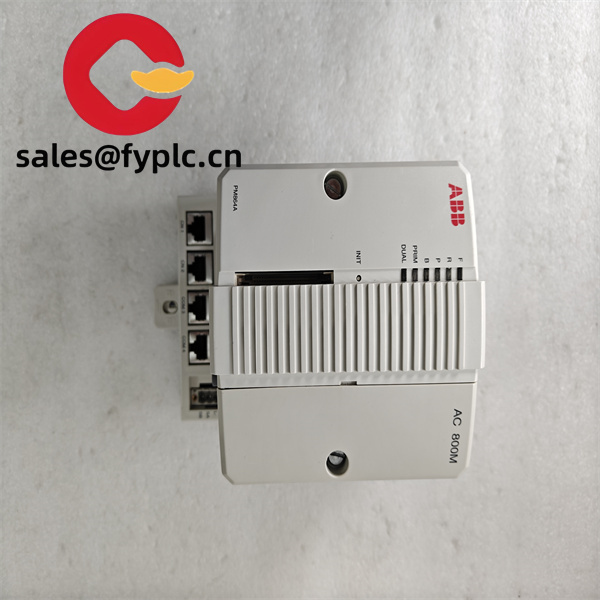

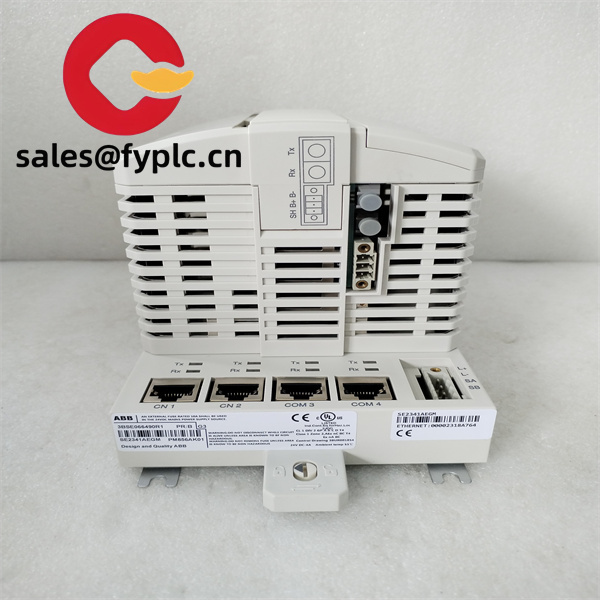

ABB PM856AK01 controller programming unit

The ABB PM864AK01 is an advanced programmable automation controller, with its core positioning as the “intelligent brain” of industrial automation systems. Whether it’s the coordinated operation of sophisticated production lines in large automotive manufacturing plants, the real-time monitoring and regulation of power generation equipment in energy production enterprises, or the precise management of complex production processes in the chemical industry, the PM864AK01, with its powerful data processing and analysis capabilities, can receive signals from various sensors such as those for temperature, pressure, and flow rate in real time. It then responds promptly, sending accurate control commands to actuators, ensuring that the entire production process runs stably and efficiently. It occupies an indispensable and crucial position in the grand landscape of industrial automation.

| Label |

Specification |

| Model Number |

PM864AK01 |

| Brand |

ABB |

| Type |

Programmable Automation Controller |

| Input Voltage |

24V DC (19.2 – 30V DC) |

| Operating Temperature |

-20°C – 60°C |

| Communication Methods |

Ethernet (10/100/1000 Mbit/s, RJ45), PROFINET, Modbus TCP |

The functional advantages of the ABB PM864AK01 are fully demonstrated in real industrial environments. Equipped with a high-performance multi-core processor and a high main frequency, it has 超强的数据处理速度. It can complete the operation and execution of complex control algorithms in an extremely short time. Even when facing the real-time influx of massive sensor data from large-scale production lines, it can handle it easily, make precise control decisions quickly, and significantly enhance production efficiency.

In terms of reliability, the PM864AK01 features a robust housing design and high-quality internal components, enabling it to withstand harsh conditions commonly found in industrial sites, such as electrical interference, mechanical vibrations, and drastic temperature changes. Its advanced self-diagnosis function can monitor all key internal indicators of the controller in real time. Once potential failure risks are detected, it immediately issues an alert, facilitating timely troubleshooting by maintenance personnel. This effectively reduces the probability of system failures, ensures the continuity of industrial production, and minimizes economic losses caused by equipment malfunctions for enterprises.

Regarding compatibility and expandability, the PM864AK01 supports a wide range of industrial communication protocols, enabling seamless integration with various devices and systems from different manufacturers. Whether it’s the integration of new equipment or the upgrade of existing systems, it can be adapted easily. Moreover, it has a powerful modular expansion capability. Users can flexibly add communication modules, I/O modules, etc., according to actual production needs, and effortlessly build personalized automation control systems to meet the ever-changing requirements of industrial production.

In the automotive manufacturing industry, the ABB PM864AK01 is widely used in vehicle assembly production lines. It precisely controls the movements of each robot, from the accurate positioning of body welding to the precise assembly of components, ensuring that every production step is carried out strictly in accordance with process standards. By monitoring production data in real time and adjusting the production rhythm promptly, it not only significantly improves the production quality and efficiency of automobiles but also greatly reduces the rejection rate, bringing huge economic benefits to automotive manufacturers.

For more information, please click below to learn more:

Reviews

There are no reviews yet.