Description

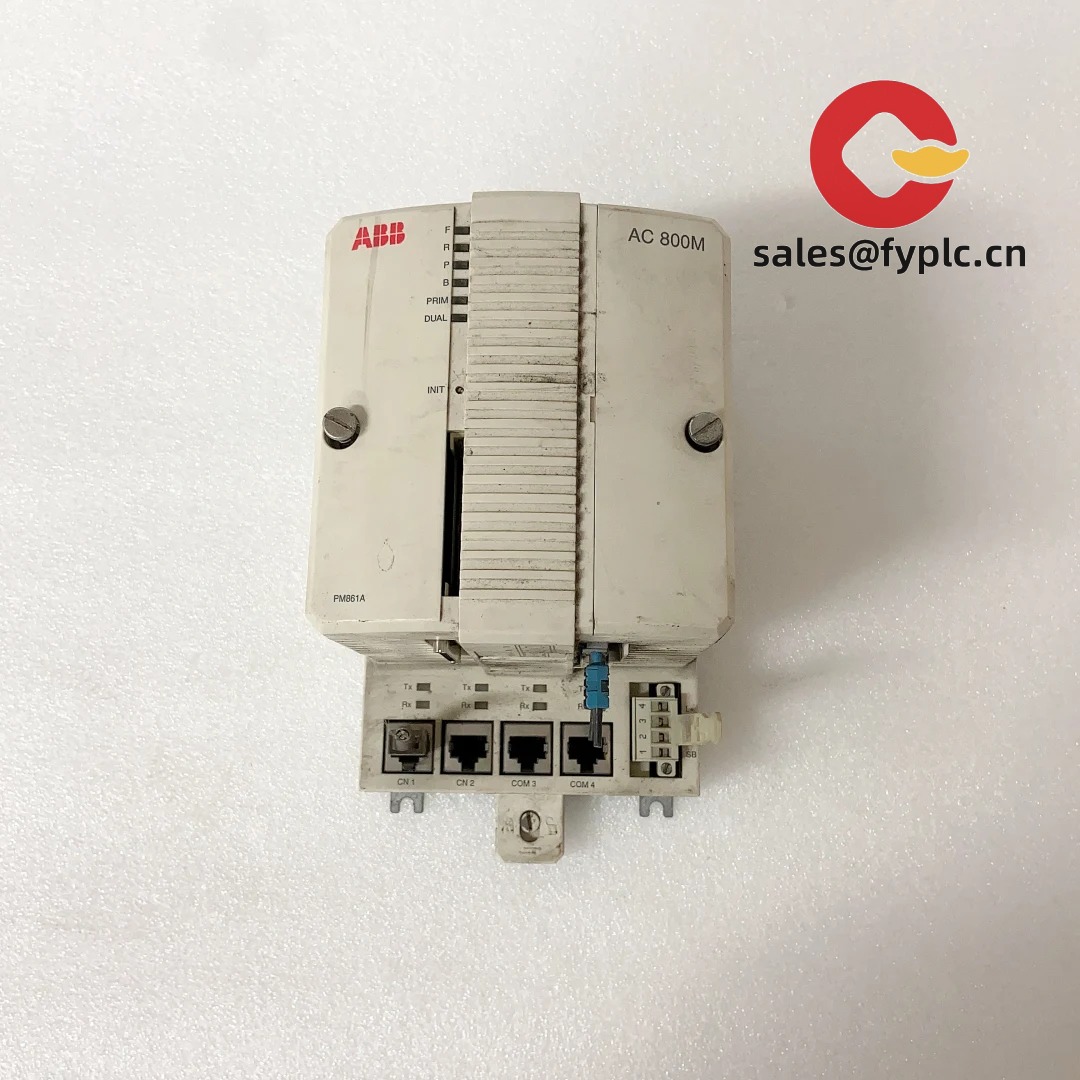

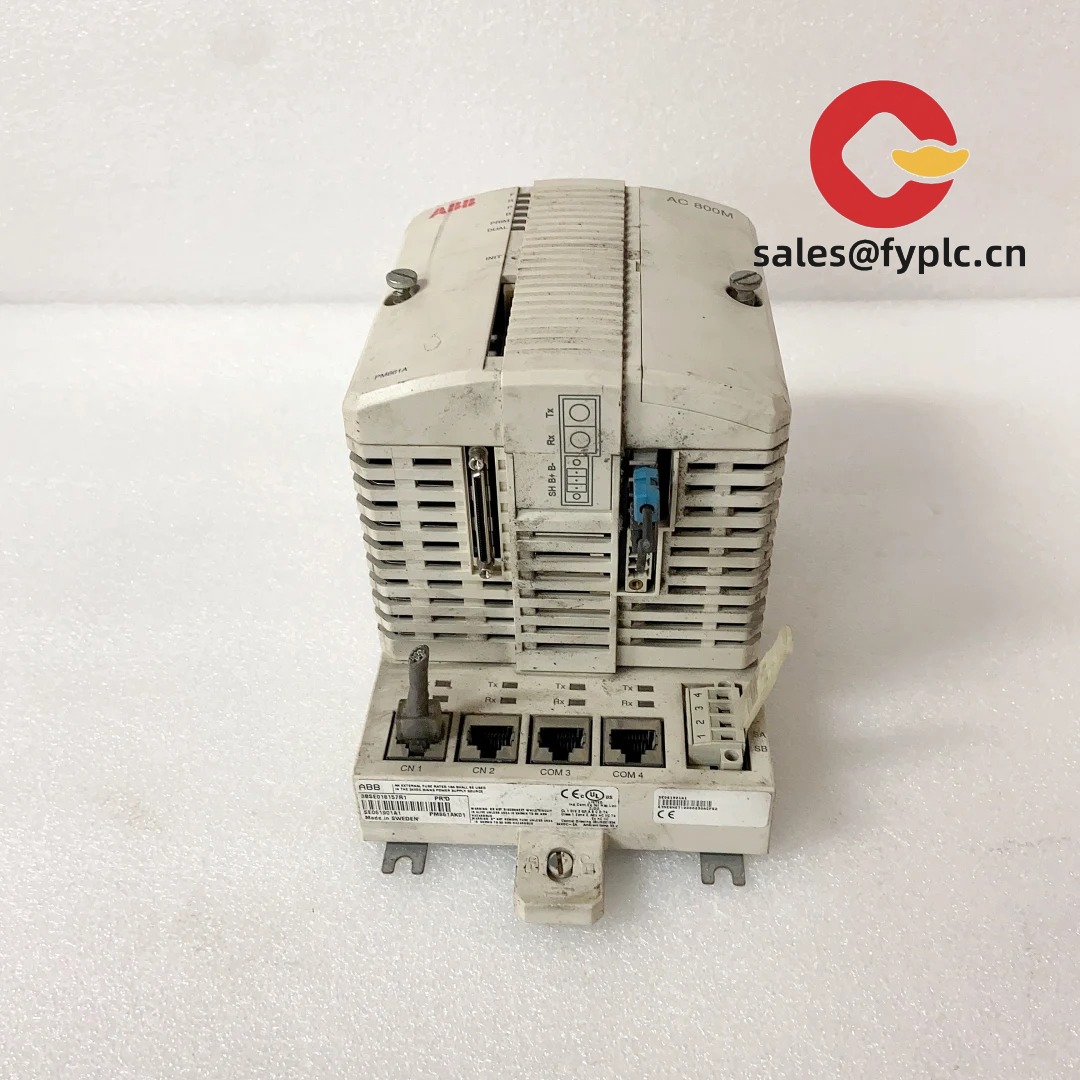

ABB PM861AK01 (3BSE018157R1) – AC 800M CPU Module for robust System 800xA control

The ABB PM861AK01 is a PM861A processor module for the AC 800M platform, commonly deployed in System 800xA architectures. From my experience, this model hits a sweet spot for mid-range process applications where you want stable scan times, dual Ethernet for plant networks, and the option to run redundant CPUs without overcomplicating the cabinet. You might notice that many upgrade projects pick PM861A when they need dependable performance, long lifecycle support, and straightforward integration with S800 I/O via CEX-bus communication modules.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: typically 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- PM861A performance for AC 800M – Suited for continuous process control and sequence logic where predictable cycle times matter.

- Dual 10/100 Ethernet – Two RJ45 ports typically used for control and plant information networks, or segmented topologies.

- Redundancy-ready – Supports CPU redundancy (with SM811/SM812) to minimize process downtime in critical units.

- CompactFlash application storage – Simplifies firmware management and application backup/restore in the field.

- Flexible I/O via CEX-bus – Connects to S800 I/O through communication modules such as CI854A (PROFIBUS), CI853 (Modbus), or CI869 (IEC 61850).

- System 800xA native – Seamless engineering in Control Builder M with proven lifecycle and service ecosystem.

Technical Specifications

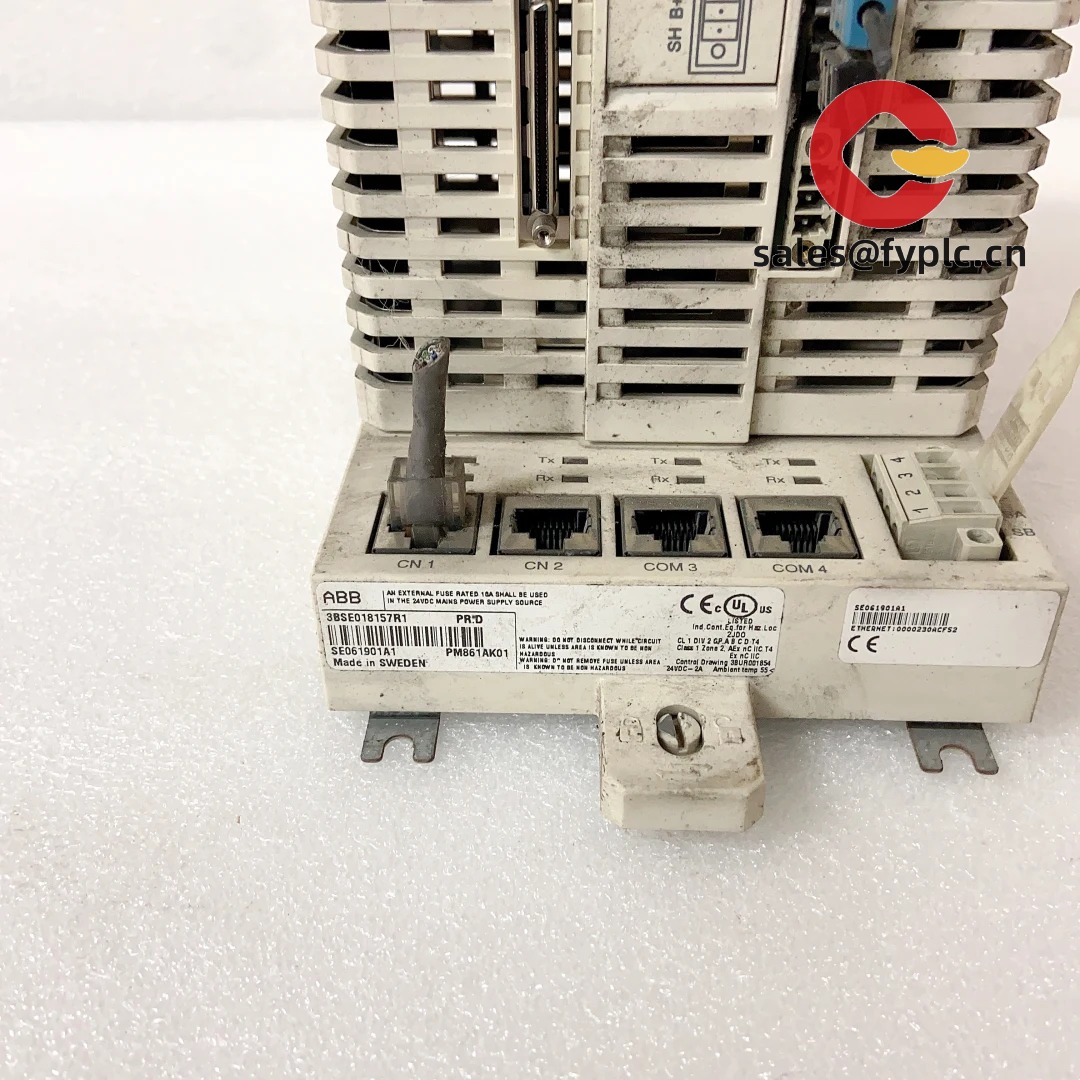

| Brand / Model | ABB PM861AK01 (Order Code: 3BSE018157R1) |

| Product Type | AC 800M Processor Module (PM861A) |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | 24 VDC nominal (typically 19.2–28.8 VDC) via AC 800M system power supply |

| Operating Temperature | 0 to +55 °C (typical control cabinet conditions) |

| Communication Interfaces | 2 × 10/100Base‑T Ethernet (RJ45), 1 × RS‑232 service port, CEX‑bus for expansion/field interfaces |

| Signal I/O Types | No onboard I/O; interfaces to S800 I/O through CI communication modules |

| Storage / Media | CompactFlash card for firmware and application storage |

| Redundancy | Redundant CPU configuration supported (with SM811/SM812) |

| Installation Method | DIN-rail mounting on AC 800M baseplate; cabinet installation per IEC/EN standards |

| System Compatibility | ABB System 800xA, Control Builder M engineering environment |

Application Fields

The PM861AK01 is typically selected for:

- Oil & gas skids, pipelines, and tank farms needing reliable sequence control

- Chemical and pharmaceutical units where deterministic batch logic is essential

- Water & wastewater plants with distributed S800 I/O and mixed protocols

- Pulp & paper sections (stock prep, machines) that benefit from CPU redundancy

- Power generation balance-of-plant and auxiliaries integrated into 800xA

- Metals, cement, and marine systems with multiple communication gateways

A maintenance manager at a utilities client told me the PM861A “seems to be the least dramatic CPU we run—updates are planned, restarts are rare, and it just keeps the loops steady.” That’s in line with what we usually see in installed bases.

Advantages & Value

- Reliability first – Proven platform with mature firmware and redundancy options for high availability.

- Compatibility – Native fit for System 800xA and S800 I/O; easy integration with PROFIBUS, Modbus, and IEC 61850 via CI modules.

- Lifecycle and spares – In many cases, PM861A provides a cost-stable upgrade path without a full system rewrite.

- Simplified engineering – Control Builder M engineering typically shortens commissioning time and eases version control.

- Cost control – Re-using existing I/O and network infrastructure often reduces project risk and spend.

Installation & Maintenance

- Cabinet and mounting – Install on the AC 800M baseplate mounted to a grounded DIN rail inside a ventilated control cabinet. Maintain clearance for airflow and field cabling.

- Power and grounding – Use a clean 24 VDC supply with proper bonding to cabinet earth. Separate signal and power wiring to limit noise.

- Networking – Segment control and information networks as needed; managed switches and VLANs are commonly used in 800xA plants.

- ESD and handling – Observe ESD precautions; avoid connecting/disconnecting modules under power unless ABB documentation explicitly allows it.

- Routine care – Periodic backup of the CompactFlash, review firmware release notes before updates, and clean dust filters during scheduled shutdowns.

- Redundancy checks – If using SM811/SM812, verify switchover behavior during planned maintenance and keep both CPUs aligned on firmware and application versions.

Quality & Certifications

- CE marked; typically UL/cUL recognized

- RoHS-compliant design

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days

Common Supporting Components (for planning)

- SM811 / SM812 – Redundancy modules for pairing two PM861A CPUs

- CI854A – PROFIBUS DP interface for S800 I/O or third-party devices

- CI853 – Modbus (typically RTU/TCP) communication interface

- CI869 – IEC 61850 communication for electrical integration

- AC 800M power supply (24 VDC) – System supply sized for CPU + modules

- CompactFlash card – Application and firmware storage media

If you’re planning a like‑for‑like replacement or a phased modernization, the PM861AK01 typically lets you reuse existing I/O and keep downtime low. Feel free to share your current firmware revision and network layout—matching these details upfront usually saves days on site.

Reviews

There are no reviews yet.