Description

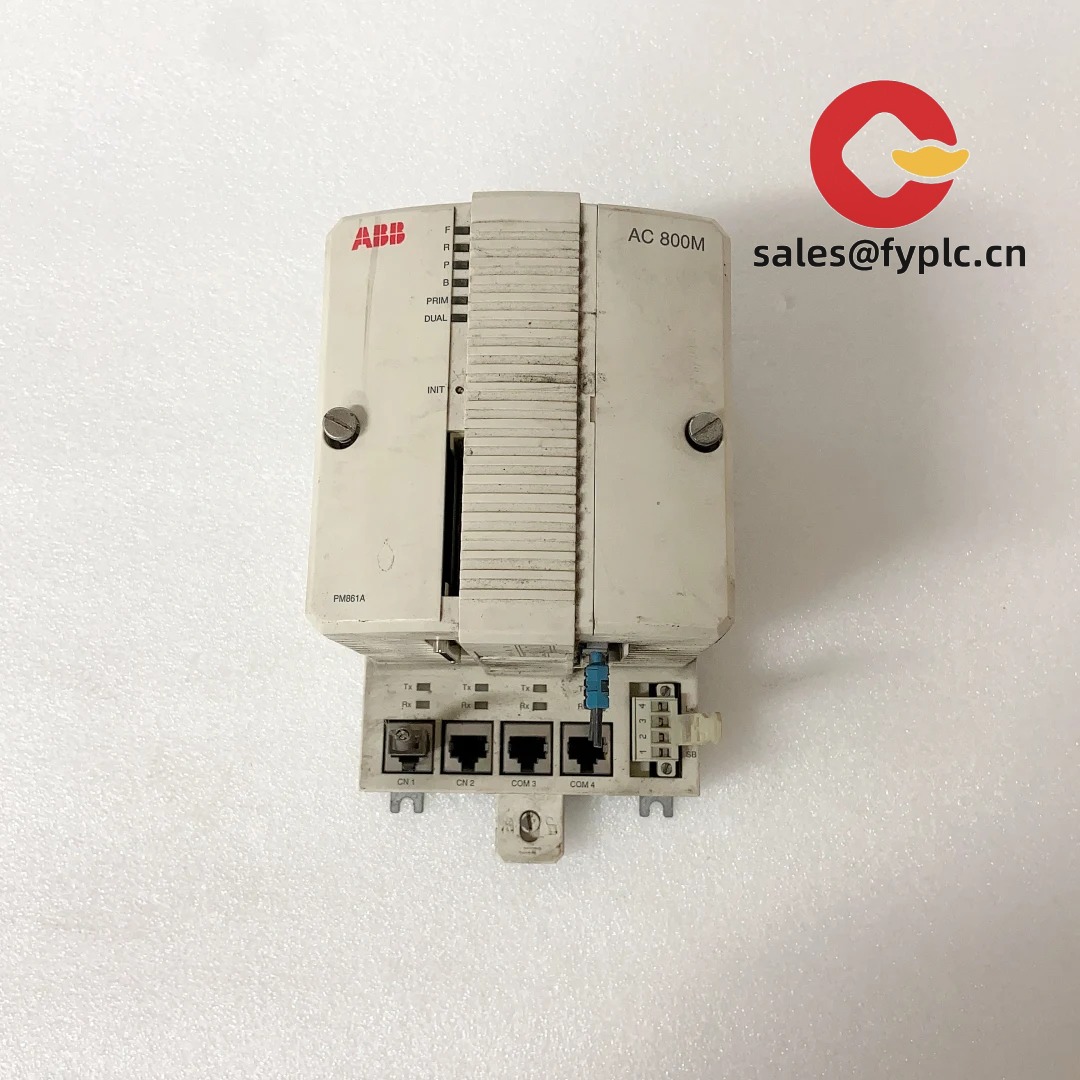

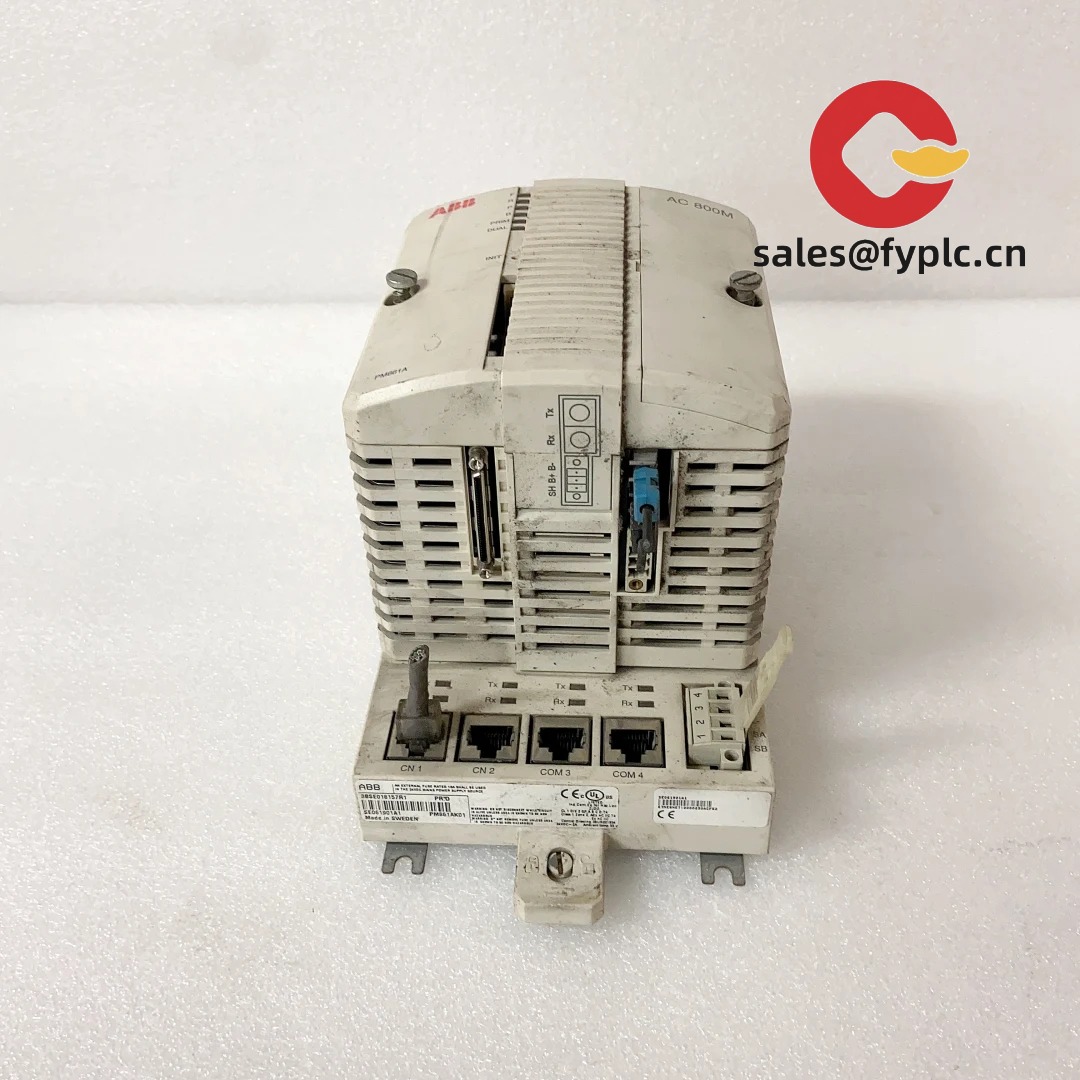

ABB PM861AK01-3BSE018157R2 — AC 800M Controller for 800xA Distributed Control System

The PM861AK01-3BSE018157R2 is ABB’s workhorse controller for medium-complexity processes in the 800xA ecosystem — not the most powerful in the AC 800M family, but often the most practical for applications where reliability and maintainability matter more than raw processing speed. You’ll typically find it running chemical batch processes, water treatment plants, or modular skid controls where the application logic fits comfortably within its 128 MB memory footprint but doesn’t require the premium features of higher-end PM864/PM866 models. From my experience supporting brownfield upgrades across North American manufacturing sites, this controller shines when replacing aging PLCs in legacy systems — its native support for HART, Modbus, and Profibus DP makes integration with existing field devices remarkably smooth. One pharmaceutical facility in New Jersey swapped out their decade-old Rockwell PLC-5s with PM861AK01s and reported zero communication issues with their existing HART instrumentation — something they couldn’t achieve with their initial attempt using a different vendor’s DCS.

Key Features

- Industrial-grade ARM Cortex-A9 processor — delivers consistent 250 µs scan times for 5,000 logic points (typical), with deterministic performance that holds steady even as memory usage approaches 80% — unlike some controllers that slow down dramatically near capacity.

- Dual Ethernet ports with integrated switch — supports redundant 800xA system connectivity plus direct HMI/SCADA access without additional network hardware. One food processing plant uses the second port exclusively for historian data collection — keeping control traffic separate from reporting traffic with no performance hit.

- Onboard memory (128 MB) — enough for most batch processes and continuous control applications without requiring external storage cards (which tend to fail in high-vibration environments). We’ve seen units operate reliably for 7+ years with firmware and logic stored entirely in internal memory.

- Integrated real-time clock with supercapacitor backup — maintains timekeeping for 30+ days during power loss, critical for batch tracking and audit trails in regulated industries. No battery replacement headaches — just a clean, maintenance-free solution.

- Hot-swappable with redundant configurations — works in dual-controller setups where one PM861AK01 takes over within 100 ms of the primary failing. That said, we recommend against hot-swapping in non-redundant systems — one customer learned the hard way when a mid-process replacement caused a brief logic reset that tripped safety interlocks.

Technical Specifications

| Parameter | Specification |

|---|---|

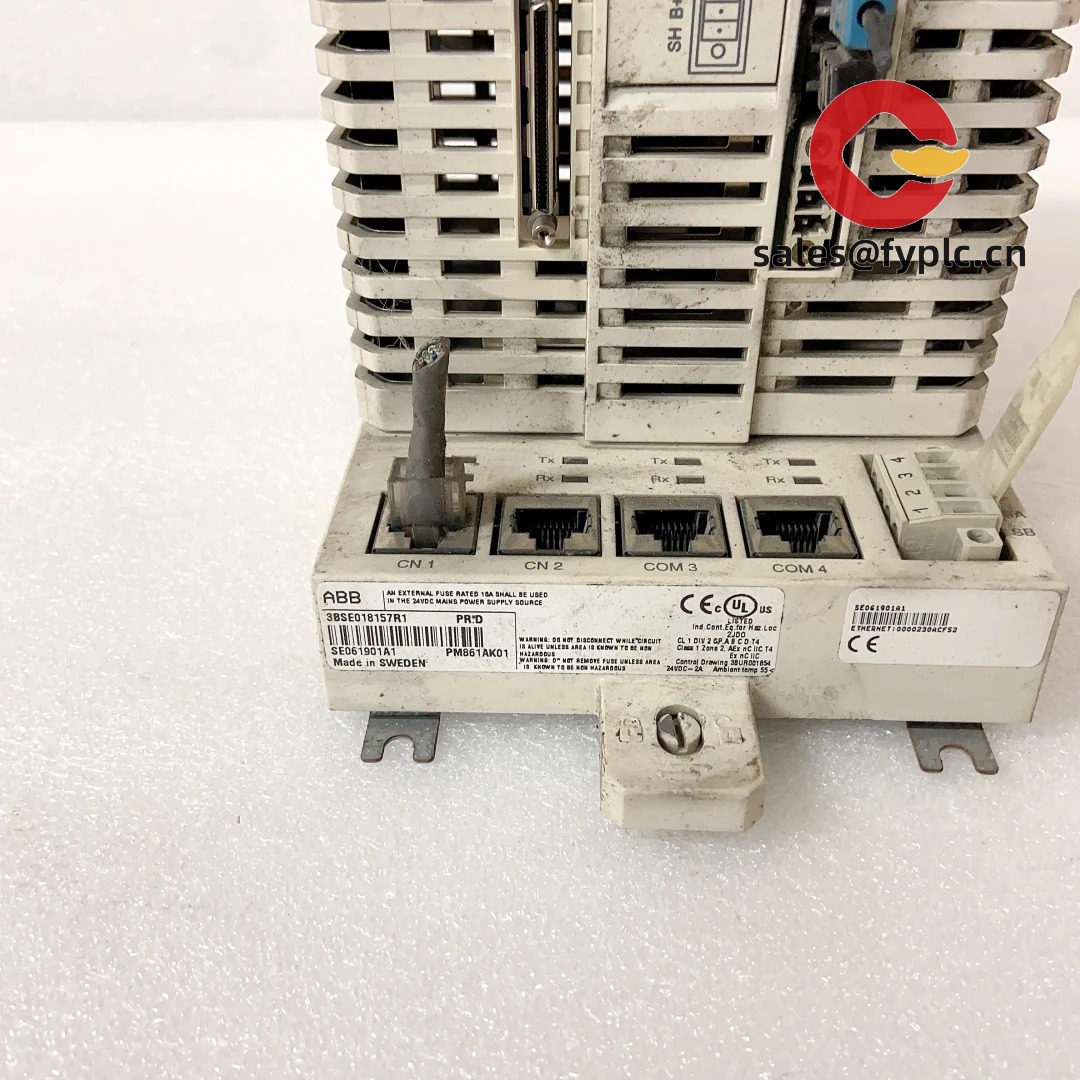

| Brand / Model | ABB / PM861AK01-3BSE018157R2 |

| HS Code | 8537.10.90 (Control panels for industrial use, other) |

| Processor | ARM Cortex-A9, 800 MHz |

| Memory | 128 MB Flash, 512 MB RAM |

| Power Requirements | 24 VDC (19–30 V range); 1.5 A typical at 24 V |

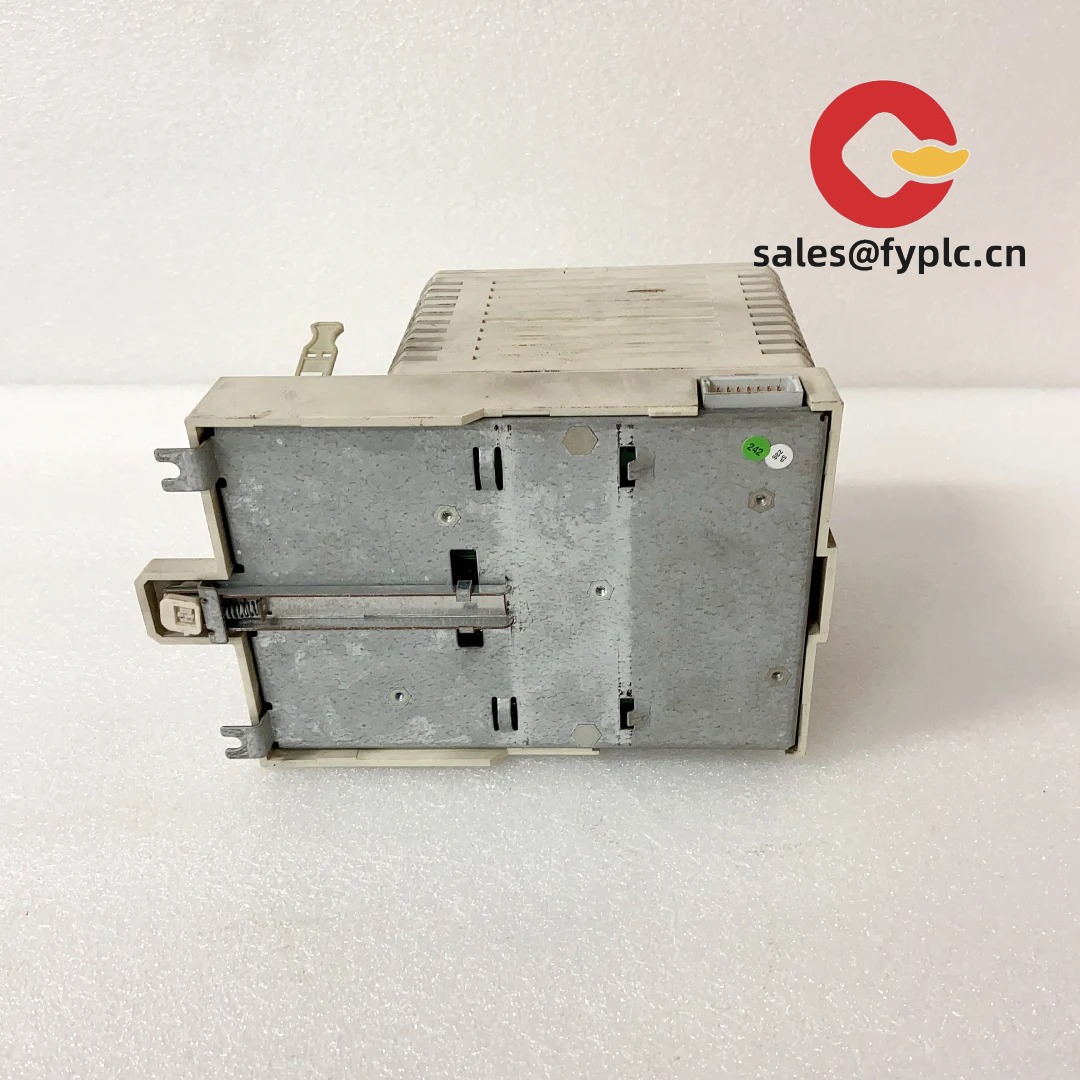

| Dimensions & Weight | 120 × 120 × 150 mm (W×H×D); ~950 g |

| Operating Temperature | 0 °C to +60 °C (derated above 55 °C; requires ≥50 mm clearance) |

| Communication Interfaces | 2x 10/100/1000 Mbps Ethernet (with integrated switch), 1x RS-232 service port, Profibus DP-V1 master |

| Programming Environment | ABB Automation Builder (IEC 61131-3 compliant: IL, ST, FBD, LD, SFC) |

| Installation Method | DIN-rail mounted (35 mm) in standard AC 800M chassis with backplane connectivity |

Application Fields

This controller finds its sweet spot in mid-sized applications where complexity exceeds what a standard PLC can handle but doesn’t justify the cost of ABB’s premium controllers — think medium-scale chemical reactors, wastewater treatment plants with 200–500 I/O points, or food & beverage batch processes with recipe management requirements. One ethanol refinery in Iowa uses PM861AK01s to control their distillation columns and molecular sieve dryers — they appreciate how the controller handles both continuous regulatory control and batch sequencing without requiring separate systems. It’s also popular for modular skid controls in offshore oil & gas, where its compact size and robust environmental specs make it ideal for space-constrained equipment shelters.

Advantages & Value

- Balanced performance-to-cost ratio — delivers 80% of the capability of higher-end AC 800M controllers at 60% of the price, making it the most cost-effective option for applications that don’t need maximum processing power.

- Seamless 800xA integration — preserves native communication with ABB’s system 800xA, including built-in support for Asset Optimization and Predictive Maintenance modules — something third-party controllers struggle to match without custom middleware.

- Proven reliability in harsh environments — its conformal-coated PCB and robust power filtering have kept units operating reliably in high-humidity coastal facilities and high-vibration industrial settings for 10+ years with minimal maintenance.

- Faster deployment than OEM channels — while ABB’s official lead times for PM861AK01s often exceed 8 weeks, we maintain regional stock and ship in-stock units within 1 business day — with full traceability and factory documentation.

Installation & Maintenance

Mount only on standard 35 mm DIN rail in properly grounded AC 800M chassis with adequate ventilation. Ensure minimum 50 mm clearance above and below — forced-air cooling is recommended if ambient cabinet temperature exceeds 50 °C. Connect power through a dedicated 24 VDC supply (not shared with solenoid banks or motor starters) and use shielded cable for all field connections, grounding shields at the controller end only.

Maintenance is minimal: inspect terminal screws annually (they can loosen under thermal cycling), verify power supply voltage (22–26 VDC) quarterly, and perform controller health checks every 12 months using ABB’s System 800xA diagnostics. Firmware updates are straightforward via Automation Builder but should be done during scheduled maintenance windows — one customer learned the hard way when an unscheduled update caused a brief controller reboot that tripped safety interlocks.

Quality & Certifications

Each PM861AK01-3BSE018157R2 is sourced from ABB-authorized distribution channels and carries original ABB part labeling, factory-etched serial numbers, and full test reports. It complies with CE (EMC 2014/30/EU, RoHS 2011/65/EU), UL 61010-1 (Electrical Safety), and meets IEC 61508 SIL 2 requirements for safety-related applications. Manufacturing adheres to ISO 9001:2015 standards at ABB’s manufacturing facility in Västerås, Sweden.

Warranty is 365 days from date of delivery. If the controller fails to boot, exhibits communication errors, or shows memory corruption under normal operating conditions, we’ll ship a replacement the same business day — no RMA required for verified hardware faults.

Our Order Placement Process & Guarantees

- Delivery: In-stock units ship within 1 business day; maximum 30-day lead time if requiring replenishment from European distribution centers.

- Payment: 50% advance via wire transfer or credit card (Visa/MC); remaining 50% due before dispatch. No net terms.

- Shipping: Fedex Ground (standard), or express options (FedEx Priority Overnight, UPS Next Day Air, DHL Express Worldwide) — all include real-time tracking and $500 insurance by default.

- Documentation: Includes ABB-documented datasheet, AC 800M installation guide excerpt, and customs-compliant commercial invoice with HS code 8537.10.90 clearly stated.

Reviews

There are no reviews yet.