Description

ABB PP825 (3BSE042240R1) Panel 800 HMI – Reliable operator interface for machine and process visualization

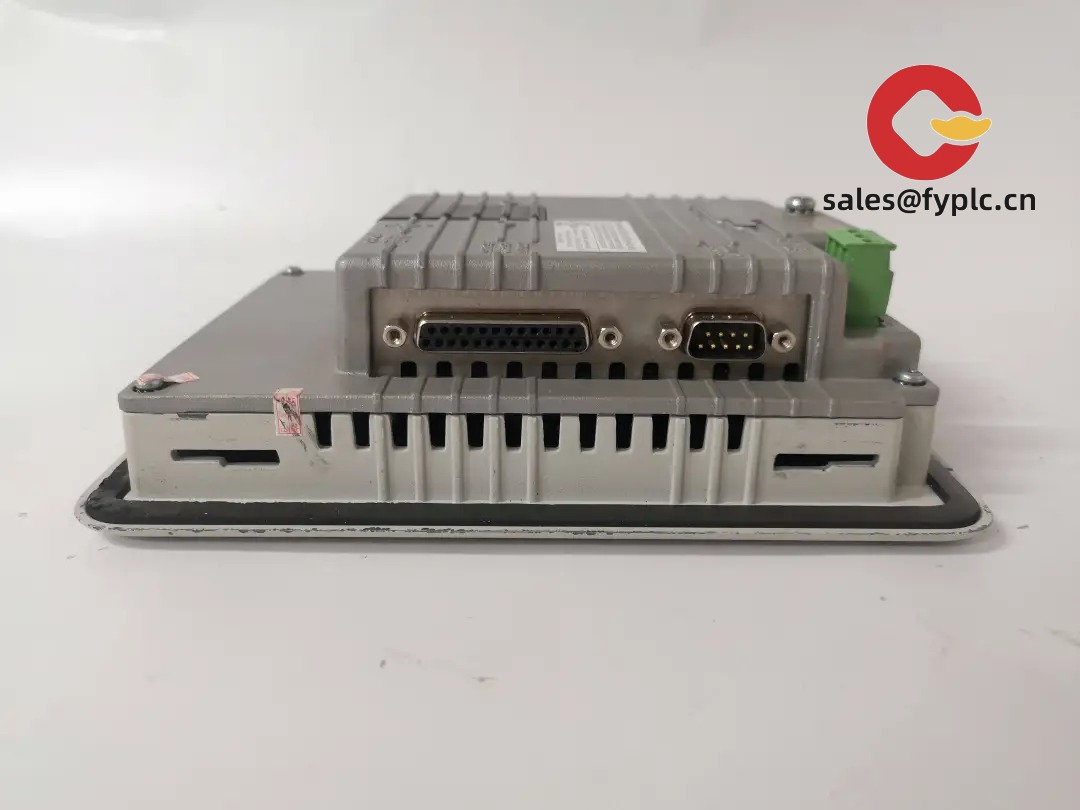

The ABB Panel 800 PP825, part number 3BSE042240R1, is a robust HMI operator panel used on hundreds of ABB-driven lines. From my experience, it fits well when you need a dependable, panel-mounted touchscreen for day-to-day operations, recipes, alarms, and line diagnostics. It’s typically installed as a drop-in replacement on existing ABB 800xA/AC 800M systems, yet it also plays nicely with third-party PLCs via common protocols like Modbus TCP/RTU or Ethernet-based networks. One thing I appreciate is the practical balance—industrial-grade build, IP-rated front, and straightforward engineering with Panel Builder 800 runtime.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Industrial HMI from Panel 800 family – A proven platform for operator control and monitoring in harsh environments.

- 24 VDC power – Simplifies cabinet design; typically tolerant to industrial supply variations.

- IP-rated front panel – When correctly mounted with the gasket, the front typically meets IP65/NEMA 4X for washdown and dust.

- Built-in communications – Ethernet (10/100), RS‑232/RS‑485, and USB for engineering, data exchange, and backup.

- Protocol flexibility – Common drivers available in many cases (e.g., Modbus TCP/RTU, Ethernet-based PLC links) to integrate with ABB and non-ABB controllers.

- Panel Builder 800 runtime – Engineering workflow many ABB users already know; reduces commissioning time.

- Alarm, trend, and recipe tools – Practical operator functions without extra boxes.

- Rugged design – Designed for continuous operation in industry; typically supports 0…50°C ambient when panel-mounted.

Technical Specifications

| Brand / Model | ABB Panel 800 – PP825 (3BSE042240R1) |

| HS Code | 8537.10 (Boards/panels/consoles for electric control, for a voltage ≤ 1000 V) |

| Power Requirements | 24 VDC nominal; typical tolerance 18…32 VDC; use a stabilized, protected supply |

| Operating Temperature | Typically 0…+50 °C (panel-mounted), 10–90% RH non-condensing |

| Signal I/O Types | HMI communications (no onboard analog/digital I/O); connects to PLCs/DCS via ports |

| Communication Interfaces | 1× Ethernet 10/100Base‑T (RJ45), 1× RS‑232, 1× RS‑485, USB host/device (typical) |

| Front Protection | IP65/NEMA 4X (front, when properly installed); rear typically IP20 |

| Installation Method | Panel mounting with rear clamps and gasket; horizontal/vertical as per cutout guidance |

| Engineering/Runtime | Panel Builder 800 HMI runtime; drivers available for Modbus TCP/RTU and other common networks |

Application Fields

This model is widely used across discrete and process industries. Typical placements include:

- ABB 800xA/AC 800M workcells and OEM machines needing a compact operator panel.

- Pulp & paper, metals, and material handling lines where operators need trends, recipes, and alarm pages at a glance.

- Water/wastewater skids and energy applications, often communicating via Modbus TCP or RTU with third-party PLCs.

- Food & beverage packaging stations and conveyors that require an IP-rated, easy-to-clean front.

A packaging OEM told us they swapped a PP825 into an older enclosure door using the existing cutout and had operators back online in under an hour—no surprises with wiring or protocols. That seems to be the sweet spot for this series.

Advantages & Value

- Drop‑in replacement – In many cases, you can reuse the panel cutout and engineering environment, minimizing downtime.

- Compatibility – Works well with ABB controllers and communicates with non-ABB PLCs via well-known protocols.

- Lifecycle support – Panel 800 family has stable availability and documentation, which helps spares management.

- Cost control – Fewer external gateways thanks to built-in ports; straightforward commissioning saves engineering hours.

- Technical backup – Pre-shipment functional testing available on request; configuration assistance if needed.

Installation & Maintenance

- Panel mounting – Follow ABB’s cutout and clamp torque guidance; ensure the gasket is evenly compressed for IP65.

- Power & grounding – Use a stabilized 24 VDC supply with proper PE grounding. From my experience, a dedicated 24 VDC/2–3 A rail gives headroom for backlight and USB devices.

- Wiring practice – Keep Ethernet/serial away from VFD/motor cables; use shielded twisted pairs for RS‑485 and bond shields at one end to avoid ground loops.

- Cabinet environment – Provide ventilation to keep internal temperature within spec; avoid direct sunlight and high vibration zones.

- Maintenance – Clean the touchscreen with non-abrasive wipes; back up the HMI project to USB after any change; review firmware/driver updates during scheduled shutdowns. The front gasket is a consumable—inspect during annual PMs.

- Spare strategy – Keeping one PP825 pre-imaged on the shelf typically cuts MTTR dramatically during unplanned events.

Quality & Certifications

- Certifications – CE and UL/cUL markings are commonly available for the Panel 800 series; RoHS compliant in most cases.

- Ingress protection – Front IP65/NEMA 4X when correctly installed.

- Warranty – 365-day warranty from our side; manufacturer warranty is typically 12 months depending on region and revision.

- Traceability – Supplied with full model and part number (PP825, 3BSE042240R1) for easy asset registration.

Optional Accessories & Supporting Components

- DIN-rail 24 VDC industrial power supplies (to match the panel’s load and headroom).

- Replacement front gasket and mounting clamp sets for IP compliance after service.

- Industrial USB memory for project backup/restore and data logging.

- Shielded RS‑485 cables and Ethernet patch cords rated for industrial cabinets.

Note: Specifications above reflect typical configurations of the ABB PP825 within the Panel 800 family. For a specific firmware, driver set, or exact cutout drawing tied to 3BSE042240R1, we can share the current datasheet upon request.

Reviews

There are no reviews yet.