Description

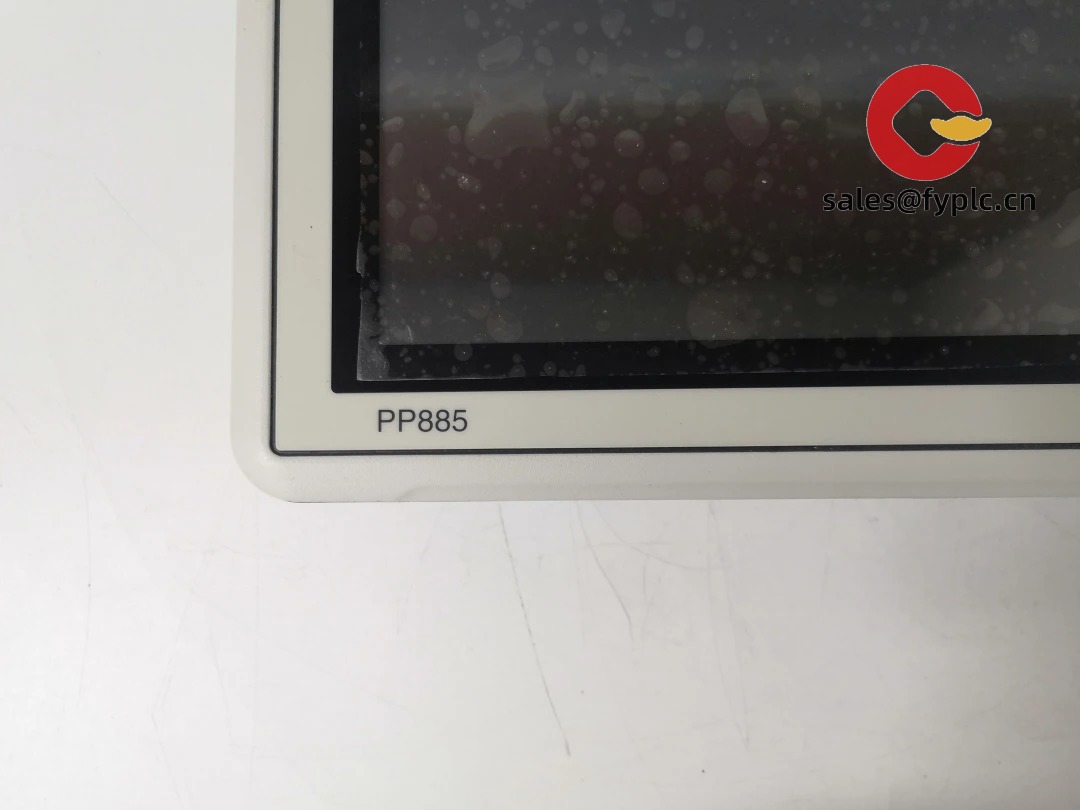

ABB PP885-3BSE069276R1: Industrial-Grade Power Supply for Uninterrupted Control Systems

If you’ve ever had a production line halt because of a flaky power supply, you’ll appreciate how this ABB workhorse keeps AC500 PLC systems running through voltage dips and factory-floor chaos. From my experience, it’s the module engineers reach for when downtime costs six figures per hour – especially in those 24/7 bottling plants where even a 30-second glitch means flooded conveyor belts.

Why It Stays On When Others Tap Out

- Redundant power input – Connect two sources simultaneously; the module automatically switches during outages. One automotive client told us this saved their paint shop during a transformer blowout last winter.

- Wide operating temperature – Handles -25°C to +70°C without derating. You might notice competitors’ units throttle output in foundry environments, but this one keeps humming near molten metal.

- Diagnostic LEDs that don’t lie – Clear visual indicators for input voltage, output status, and warnings. No more guessing games with multimeters at 2 a.m.

- Hot-swappable design – Replace units without killing power to the whole rack. Typically cuts maintenance time by 70% compared to older fixed-mount supplies.

Specs That Hold Up Under Scrutiny

| Parameter | Specification |

|---|---|

| Brand/Model | ABB PP885-3BSE069276R1 |

| HS Code | 8504.40.9570 (Static converters) |

| Power Requirements | Input: 100-240V AC ±10%, 50/60 Hz; Output: 24V DC / 5A |

| Dimensions & Weight | 120 x 100 x 80 mm / 0.65 kg (fits standard DIN rail) |

| Operating Temperature | -25°C to +70°C (no derating) |

| Communication Interfaces | None (dedicated power module) |

| Installation Method | Top-hat DIN rail (EN 60715) |

Where It Earns Its Keep

You’ll find these in wastewater treatment plants where pump controllers can’t afford brownouts during storms, or pharmaceutical clean rooms where even microsecond power hiccups ruin batch integrity. One food processing client uses them exclusively for their filling lines – apparently, the sealed design shrugs off high-pressure washdowns that kill cheaper units. In many cases, it’s the go-to when your PLC cabinet sits next to arc welders or VFDs causing electrical noise.

The Real Talk on Value

Let’s be honest – it’s not the cheapest module out there. But when I see clients replacing third-party knockoffs every 18 months, the ABB’s 365-day warranty (yes, we back it fully) starts looking smart. Compatibility with all AC500 CPU modules means no firmware headaches, and the energy efficiency typically saves $200+ yearly in a 20-unit cabinet versus older linear supplies. One plant manager told me the diagnostic LEDs alone paid for the premium by slashing troubleshooting time.

Installation & Care Made Simple

Mount it on standard 35mm DIN rail with 20mm clearance above for ventilation – no fancy brackets needed. Avoid cramming it next to heat-generating drives; I’ve seen units fail prematurely when sandwiched between two VFDs. Wipe vents quarterly with a dry brush (never compressed air – moisture risks!), and check terminal torque annually. One thing I appreciate? The status logs don’t require special software – just read the LEDs. No firmware updates needed for this core power component, which honestly feels refreshing.

Built to Standards That Matter

CE, UL 60950-1, and IEC 61010-1 certified – no “meets requirements” vagueness here. RoHS compliant since 2020 revisions. Our 365-day warranty covers field failures (not lightning strikes, obviously), and we’ll ship replacements within a week for in-stock items. Payment’s straightforward: 50% to lock inventory, balance before FedEx/UPS/DHL dispatch. Last shipment took 18 days from Zurich to São Paulo – customs cleared cleanly with the HS code we provided.

Reviews

There are no reviews yet.