Description

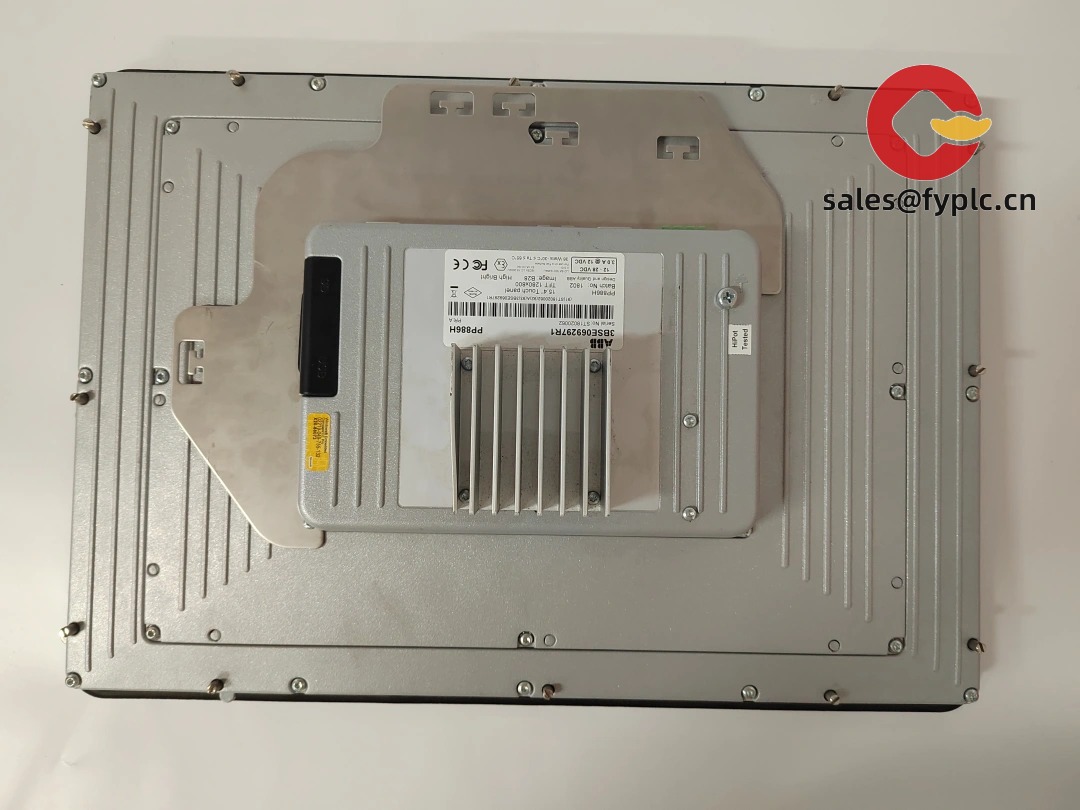

ABB PP886H (3BSE069297R1) – Panel 800 HMI for reliable machine and process visualization

The ABB PP886H, part number 3BSE069297R1, sits in ABB’s Panel 800 family and is designed as a robust operator interface for PLC and DCS applications. From my experience, this model is a good fit when you want a dependable 24 VDC HMI with Ethernet and serial connectivity, solid front-panel protection, and straightforward engineering via ABB’s Panel Builder 600. You might notice that it integrates smoothly with ABB AC500/AC 800M systems and, in many cases, talks to third‑party PLCs over common protocols like Modbus TCP/RTU—handy for mixed-vendor sites.

Our Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: Typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Rugged HMI for industrial panels – Panel‑mount design with a sealed front that typically meets IP65, suitable for cabinet doors and machine fronts.

- 24 VDC power – Standard SELV/PELV supply simplifies integration in most control cabinets.

- Ethernet and serial connectivity – Typically includes 10/100 Ethernet, RS‑232, and RS‑485 for linking ABB and third‑party PLCs.

- USB for service and backup – USB ports are usually available for project download, recipe handling, and quick backups.

- Panel Builder 600 engineering – Speeds up HMI design with reusable templates, alarm handling, and trend objects.

- Wide protocol library – In many cases supports Modbus TCP/RTU and drivers for major PLC brands, easing mixed‑vendor upgrades.

- Long lifecycle – ABB’s Panel 800 series is well established, which typically helps with long-term maintainability and spare availability.

Technical Specifications

| Brand / Model | ABB PP886H (Part No. 3BSE069297R1) |

| Product Family | Panel 800 HMI operator panel |

| HS Code | 8537.10 (Industrial control panels) |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC SELV/PELV) |

| Operating Temperature | 0 to +50 °C (panel-mounted, typical) |

| Signal Input/Output Types | Touchscreen operator input; no onboard discrete I/O |

| Communication Interfaces | 1× 10/100 Ethernet; 1× RS‑232; 1× RS‑485; USB (host/device, typical) |

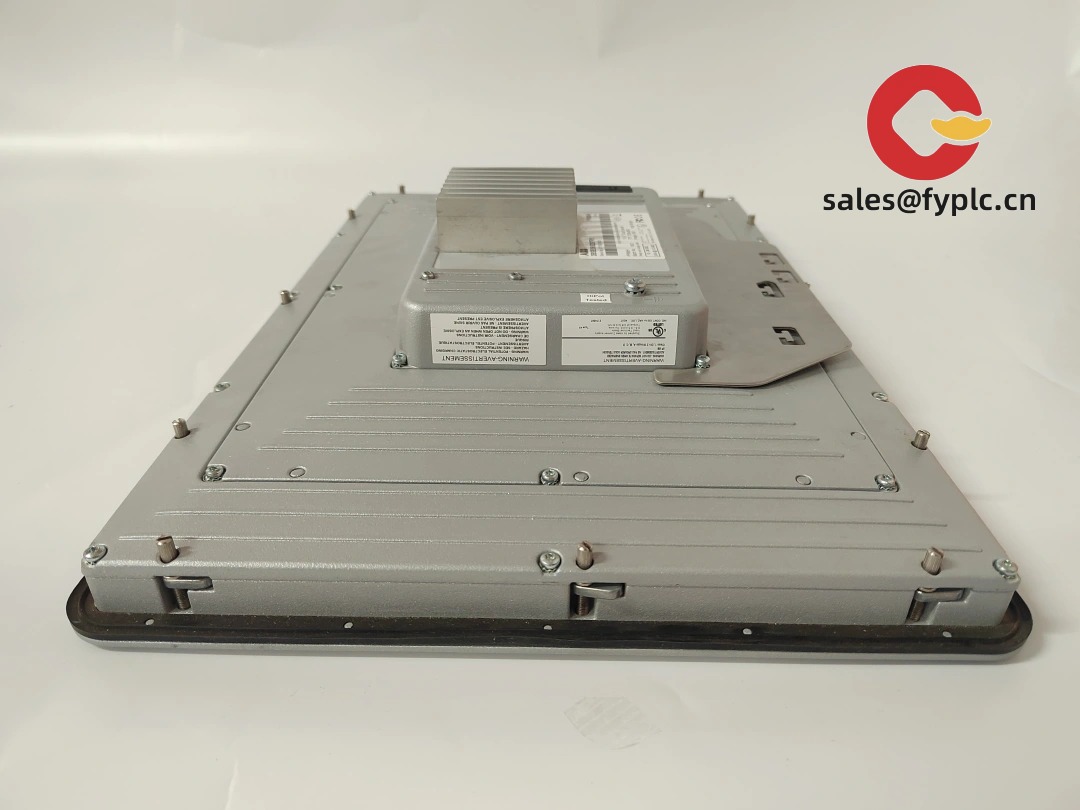

| Installation Method | Panel‑mount (flush) with mounting clips; cabinet door or HMI panel |

| Engineering Software | ABB Panel Builder 600 |

| Protection (Front/Rear) | Typically IP65 (front) / IP20 (rear) |

Application Fields

The PP886H is commonly used in machine automation and process skids where a reliable front-end HMI is needed. Typical scenarios include:

- Packaging, filling, and OEM machinery requiring quick operator interaction and recipe handling

- Water & wastewater lift stations and small treatment units with remote Ethernet access

- Metals, chemicals, and food & beverage lines needing clear alarm management and trends

- Utilities and building services panels (pumps, HVAC, CHP) in distributed control architectures

One thing I appreciate is how it fits as a drop‑in replacement in many older HMI cutouts, reducing panel rework. A recent OEM told us they swapped to PP886H across a washdown area line; the IP‑rated front and 24 VDC simplicity kept downtime to a minimum.

Advantages & Value

- Reliable platform – Stable runtime and long lifecycle components help minimize unexpected stoppages.

- Interoperability – Works well with ABB AC500/AC 800M and, in many cases, third‑party PLCs via standard drivers.

- Lower total cost – Compared to a full panel PC, this HMI usually cuts power use, heat, and maintenance.

- Easy engineering – Panel Builder 600 speeds deployment and keeps project versions organized for service teams.

- Serviceability – USB backup/restore and common 24 VDC supply simplify field support.

Installation & Maintenance

- Cabinet & mounting – Install on a flat, rigid panel with the supplied gasket and clips. Maintain even torque to preserve the front IP seal.

- Power & wiring – Use a regulated 24 VDC SELV/PELV supply with proper grounding. Keep Ethernet and serial runs away from noisy power cables; use shielded twisted pair where practical.

- Ventilation – Provide airflow in the enclosure to keep ambient within the specified operating range, especially near VFDs or power supplies.

- Safety – De‑energize before service. Follow ESD practices when handling connectors and media.

- Routine care – Periodically back up the HMI project to USB, clean the touch surface with a non‑abrasive cloth, and review logs/alarms. Firmware updates from ABB can be applied during scheduled maintenance.

- Spares – Keeping a spare front gasket and an imaged USB stick typically reduces MTTR.

Quality & Certifications

- CE conformity for industrial environments

- UL/cUL listings (typical for Panel 800 series)

- RoHS compliance; manufactured under ISO 9001 quality systems

- Manufacturer’s standard warranty applies; our coverage is 365 days

Suggested Supporting Components

- 24 VDC DIN‑rail power supply (e.g., ABB CP‑E series) sized for the HMI and peripherals

- Industrial Ethernet switch (unmanaged or managed) for PLC/HMI/SCADA segmentation

- Shielded Ethernet and RS‑485 cabling with proper grounding hardware

- USB memory stick for project backups and recipe management

- Replacement panel gasket and mounting clips

Reviews

There are no reviews yet.