Description

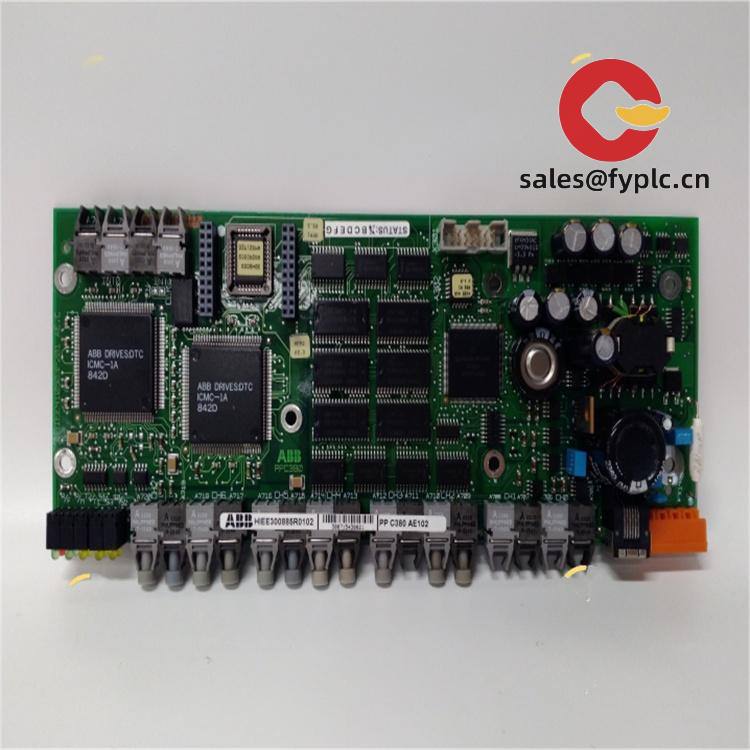

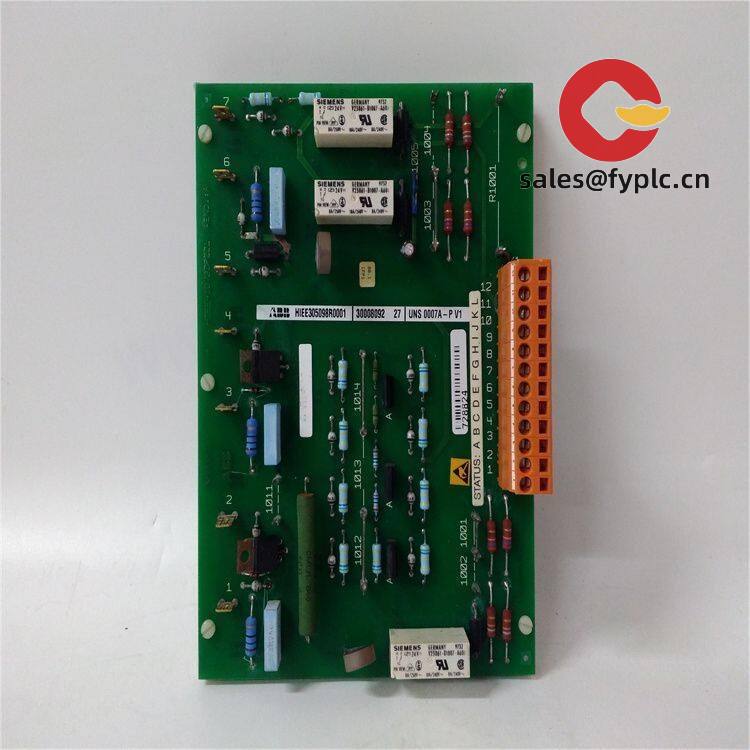

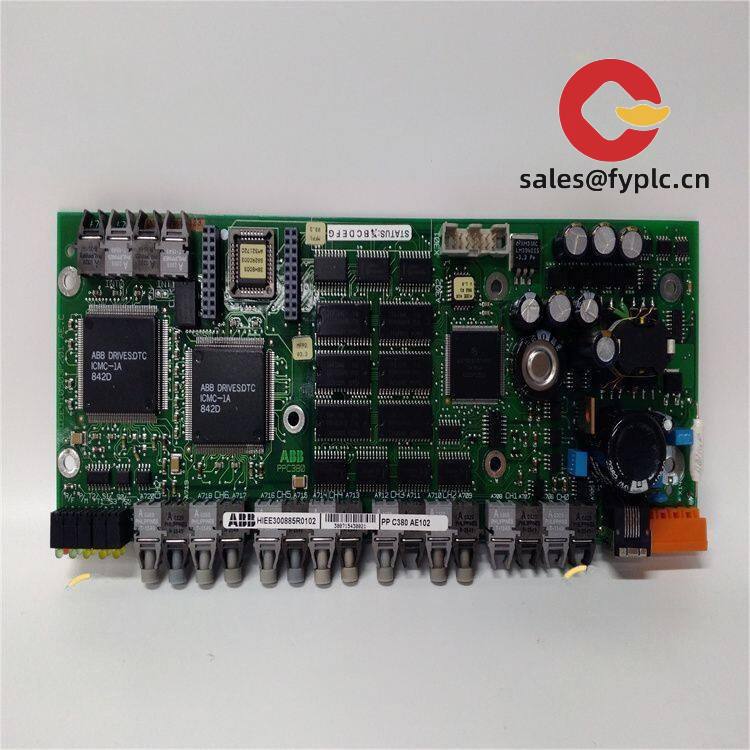

ABB PPC380AE102 HIEE300885R010 — High-Integrity Emergency Stop & Safety Logic Controller

Let’s cut to the chase: this isn’t just another PLC module—it’s ABB’s dedicated safety logic controller built for critical shutdown functions in process and power industries. I’ve seen it deployed in gas compressor skids where a 120ms response time isn’t optional—it’s what keeps the relief valve from lifting. It sits between field safety devices (like E-stops, light curtains, or turbine overspeed sensors) and final elements (valves, breakers, motor starters), handling SIL2-certified logic per IEC 61508 and IEC 61511.

Key Features

- Dual-channel, hot-standby architecture: One thing I appreciate is how it handles channel failure—no system halt, no manual switchover. The backup channel picks up within milliseconds, and you get a clear diagnostic event in the control system (via Profibus DP or Modbus RTU).

- Built-in diagnostics for all inputs/outputs: You might notice that every digital input has short-circuit and open-wire detection—and each output includes load monitoring. That means fewer “ghost faults” during commissioning, especially in humid offshore cabinets.

- Configurable via ABB’s S200 Safety Designer software: From my experience, engineers typically finish logic configuration in under two days—even with custom voting schemes (2oo3, 1oo2D). No ladder logic required; it’s function-block based, with drag-and-drop safety timers and latches.

- Integrated power supply with battery-backed RAM: Keeps your safety logic intact during brief AC dips (up to 20 ms) and retains configuration for >72 hours on internal supercapacitor—no external battery pack needed.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB PPC380AE102 (HIEE300885R010) |

| HS Code | 8537.10 — Boards, panels for industrial control |

| Power Requirements | 24 V DC ±15%, 1.2 A max (including I/O load); ripple ≤ 5% peak-to-peak |

| Dimensions & Weight | 125 × 120 × 145 mm (W×H×D), ~1.4 kg |

| Operating Temperature | −25°C to +60°C (derated above 45°C for full I/O capacity) |

| Signal Input/Output Types | 16 x 24 V DC safety-rated digital inputs (SIL2), 8 x 24 V DC safety outputs (2 A per channel, short-circuit protected) |

| Communication Interfaces | Profibus DP (slave, up to 12 Mbit/s), Modbus RTU (RS-485), plus local USB port for configuration |

| Installation Method | DIN rail (TS35-15/7.5), vertical mounting preferred; requires ≥50 mm clearance above/below |

Application Fields

This controller shows up where downtime equals risk—not just cost. Think turbine emergency trip systems in combined-cycle plants, burner management in refinery fired heaters, or shutdown logic for LNG transfer pumps. One customer in Norway told me they replaced a legacy relay panel with three PPC380AE102s across separate fire zones—and cut their annual proof-test time by 65%. It also works well in water/wastewater applications requiring pump run-dry protection and level-based cascade shutdowns.

Advantages & Value

If you’re evaluating this for procurement, here’s what stands out: First, ABB’s long-term parts availability—this model has been in production since 2019, and spare modules are still actively stocked globally (unlike some discontinued safety controllers we’ve had to source from eBay last year). Second, compatibility: it talks natively to ABB Ability™ System 800xA, but also integrates cleanly into Siemens PCS7 or Emerson DeltaV via standard Profibus gateways. Third, total cost: while the unit price is higher than basic I/O modules, the reduction in wiring (no need for external safety relays), faster loop-checking, and elimination of third-party certification audits for logic often delivers ROI inside 18 months.

Installation & Maintenance

Install it in an IP54-rated cabinet with forced ventilation—especially if ambient temps exceed 40°C. Keep signal cables (particularly safety inputs) separated from power lines by at least 200 mm, or use shielded twisted pair with drain wire grounded at controller end only. For maintenance: calibrate input thresholds annually using ABB’s handheld test tool (HIEE300886R001), wipe dust off heatsinks every 6 months, and update firmware before major turnarounds—ABB releases patches roughly twice a year, mostly addressing edge-case diagnostics (e.g., false “open circuit” alarms during rapid temperature swings).

Quality & Certifications

Certified for SIL2 per IEC 61508:2010 (TÜV Rheinland Certificate No. 984251133), compliant with EN ISO 13849-1 PL e, CE-marked, UL 508 listed, and RoHS 2011/65/EU compliant. ABB backs it with a standard 365-day warranty—covers defects in materials and workmanship, including replacement of failed I/O channels. Note: firmware updates and configuration support are included free for the first year post-purchase.

Our Order Placement Process and Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (we hold regional buffer stock in Rotterdam and Singapore)

• Lead time: Up to 4 weeks maximum for non-stock—rare, but possible during Q4 component shortages

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL Express (tracking provided); customs documentation included

Reviews

There are no reviews yet.