Description

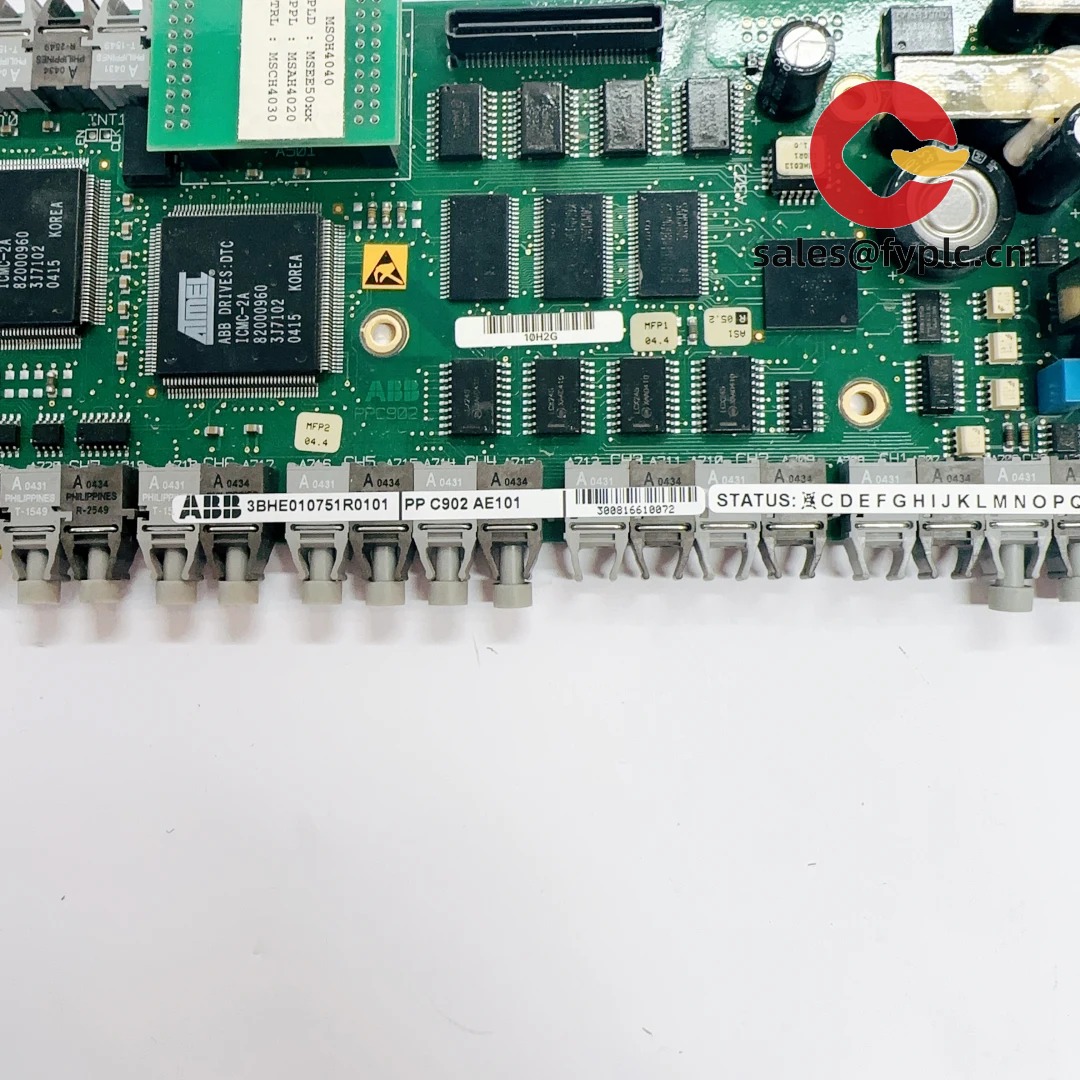

ABB PPC902AE101 (3BHE010751R0101) – Processor Board for High‑Reliability Control Systems

The ABB PPC902AE101, referenced by ABB part number 3BHE010751R0101, is a processor/CPU board from the PPC900 family, typically used as the central control board in ABB automation and drive control cabinets. From my experience, this model is favored as a like-for-like replacement in existing ABB systems where uptime and firmware continuity really matter. You might notice that it’s designed to slot straight into the system backplane, so there’s no need for external power or extra wiring—just a clean swap to get production back on track.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Testing: Functional check before shipment; photos and packing confirmation on request

Key Features

- OEM ABB module (3BHE010751R0101): Genuine processor board for the PPC900 series, ensuring firmware and hardware alignment.

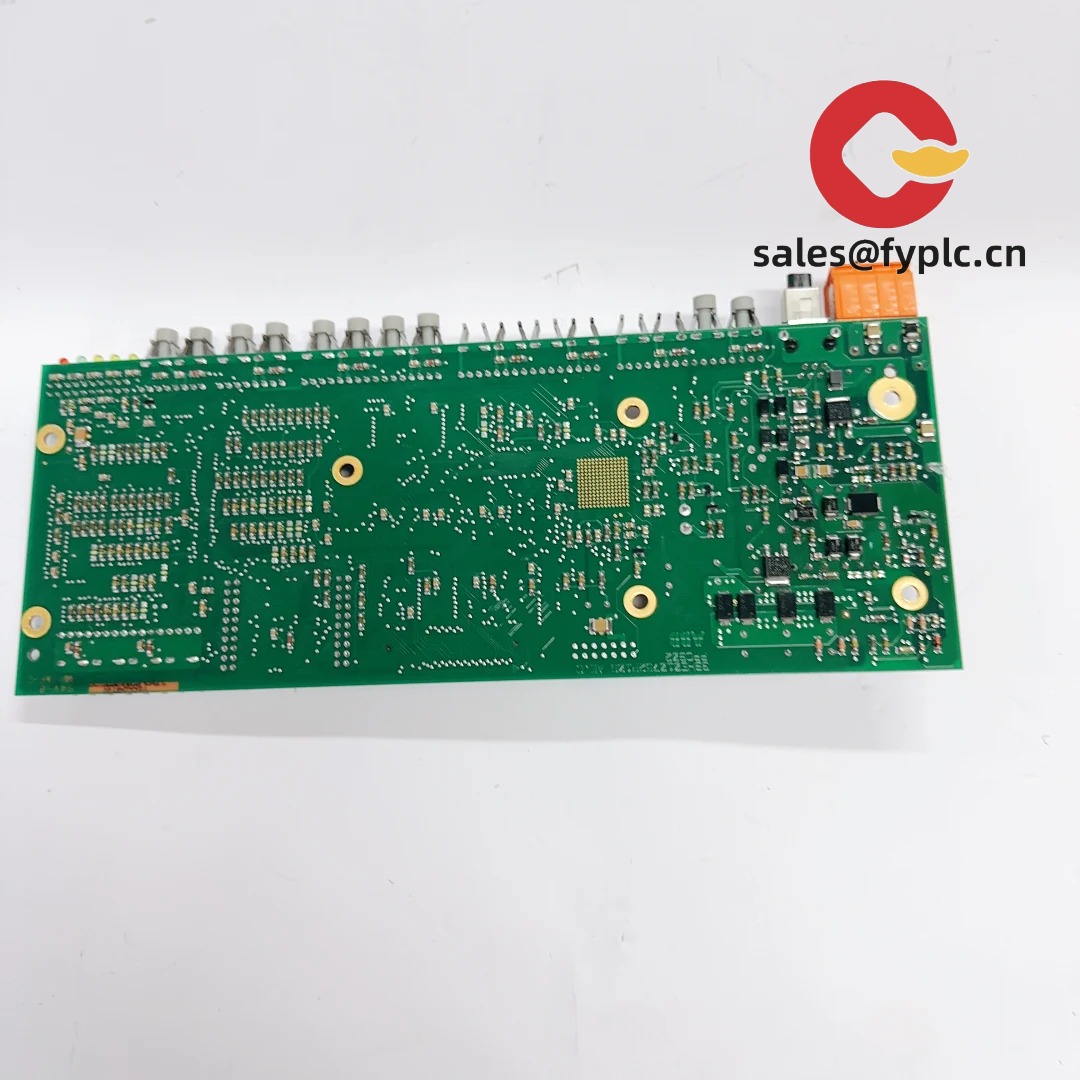

- Backplane-powered: Draws DC power from the system rack; no external PSU cabling, which typically speeds up swap‑outs.

- Drop‑in replacement: Designed for fast changeover in maintenance windows—helps minimize stop time in critical lines.

- System bus integration: Communicates via the ABB backplane; I/O is handled by dedicated modules, so no field rewiring needed.

- Service-friendly design: Front-edge access for service/diagnostics on most installations, depending on the rack and revision.

- Stable lifecycle support: Widely deployed in ABB DCS and drive control cabinets, so spares logistics are usually straightforward.

Technical Specifications

| Brand / Model | ABB PPC902AE101 (Part No. 3BHE010751R0101) |

| HS Code | 8537.10 (Programmable controllers and related control units) |

| Power Requirements | Supplied via system backplane (DC); no external power connection |

| Installation Method | Rack-mounted plug‑in board; secured with card guides/retainers in ABB cabinet |

| Signal I/O Types | No direct field I/O (handled by I/O modules); CPU handles control strategy and system comms |

| Communication Interfaces | Backplane system bus; front service/maintenance access depending on board revision |

| Operating Temperature | Typically 0…55 °C when installed in a compliant cabinet (follow ABB system manual) |

| Typical Role in System | Main CPU/processor board for ABB control/drive systems |

Application Fields

In many cases this board sits at the heart of ABB DCS nodes or drive control cabinets. Commonly seen in:

- Metals & rolling mills – coordinated drives and line control

- Pulp & paper – machine direction control and web handling

- Oil & gas – compressor/utility systems and package skids

- Power generation & utilities – balance-of-plant subsystems

- Chemicals & pharmaceuticals – continuous process control

Advantages & Value

- Reliability: Stabilized hardware platform that field techs trust—spare-on-shelf strategy usually pays off during unplanned stops.

- Compatibility: Works within the PPC900 ecosystem, helping retain existing logic, I/O structure, and cabinet wiring.

- Cost & downtime: Drop‑in replacement approach can cut changeover time, which in many plants is more valuable than the part cost itself.

- Supportability: Clear traceability via 3BHE010751R0101; makes firmware and revision alignment simpler for maintenance teams.

Maintenance feedback from a steel plant client: “Swapped the PPC902AE101 during a 2‑hour window. System booted on first try; no field I/O retesting needed. That saved our shift.”

Installation & Maintenance

- Cabinet environment: Use a clean, ventilated, and grounded cabinet; comply with ABB’s rack and clearance rules.

- ESD safety: Handle the board with ESD protection; isolate power and discharge the cabinet before removal/insert.

- Wiring & seating: No field wiring to the CPU; ensure the board is fully seated in the backplane and retaining screws are secured.

- Firmware alignment: Match firmware/loader revisions to the running system; back up application/programs prior to changeover.

- Routine care: Periodic dust cleaning with dry air; check connector condition; review event logs; consider scheduled firmware updates after validation.

Quality & Certifications

- CE compliance for industrial control environments

- RoHS conformity by production batch (where applicable)

- Manufactured under ISO 9001 quality systems (ABB)

- Warranty: 12 months from delivery (365 days)

If you’re replacing an existing PPC902AE101, sharing your current firmware/revision details typically helps us pre‑check compatibility and speed up shipment preparation. I’m happy to help with a quick matching review before you place the order.

Reviews

There are no reviews yet.