Description

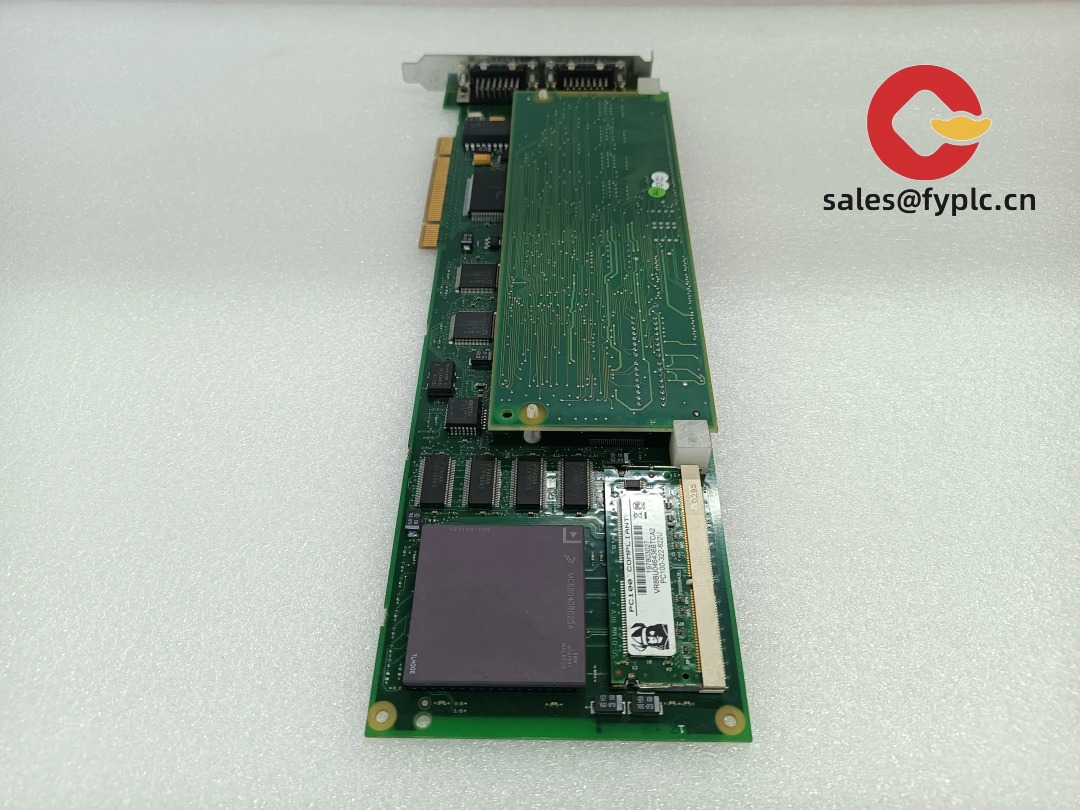

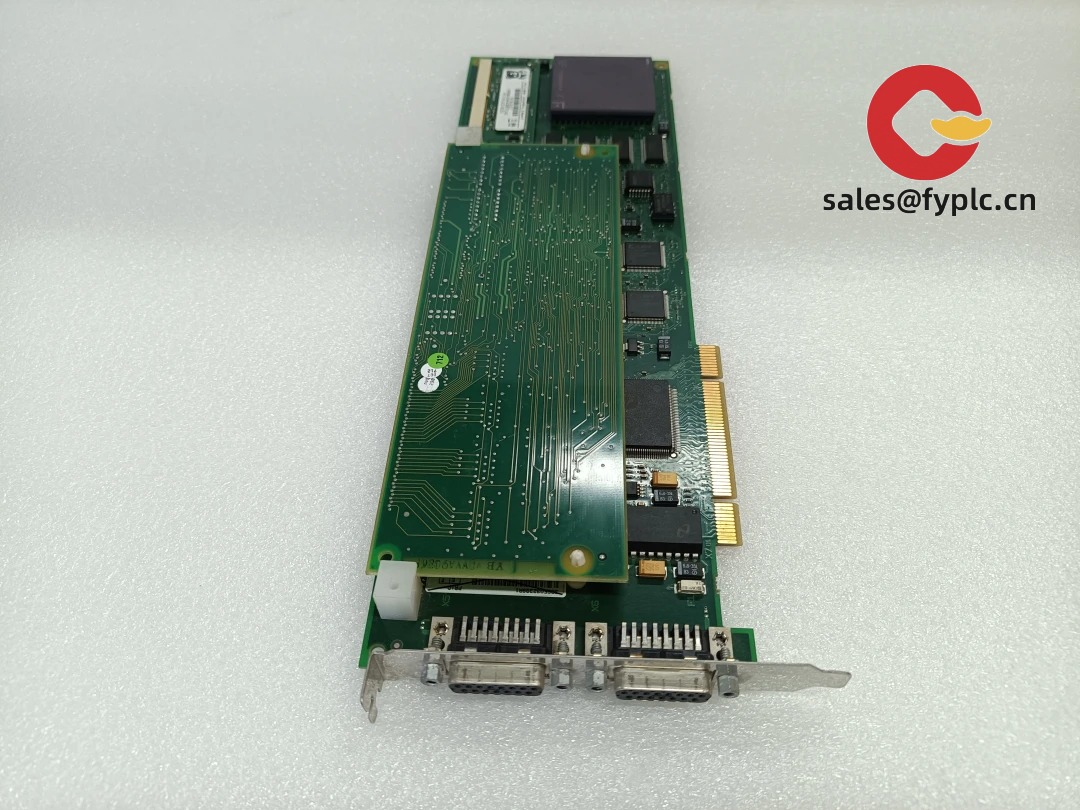

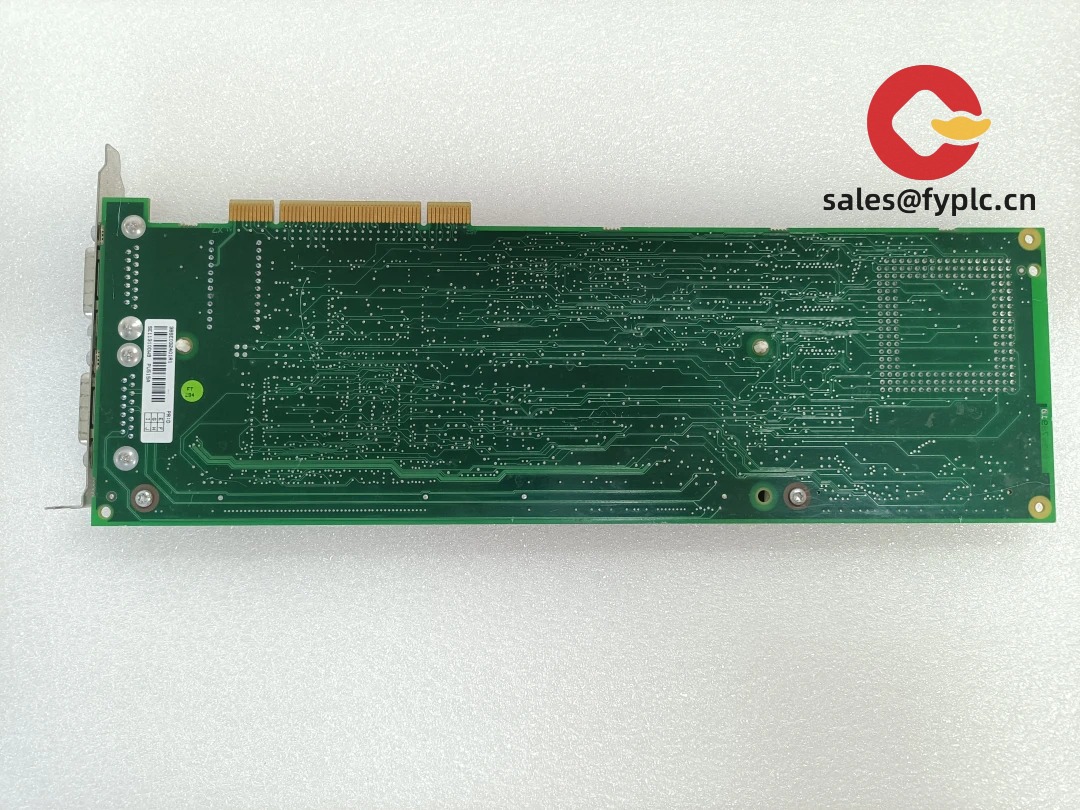

ABB PU515A RTA Board (3BSE032401R1) – Controller-internal interface board for ABB DCS maintenance and upgrades

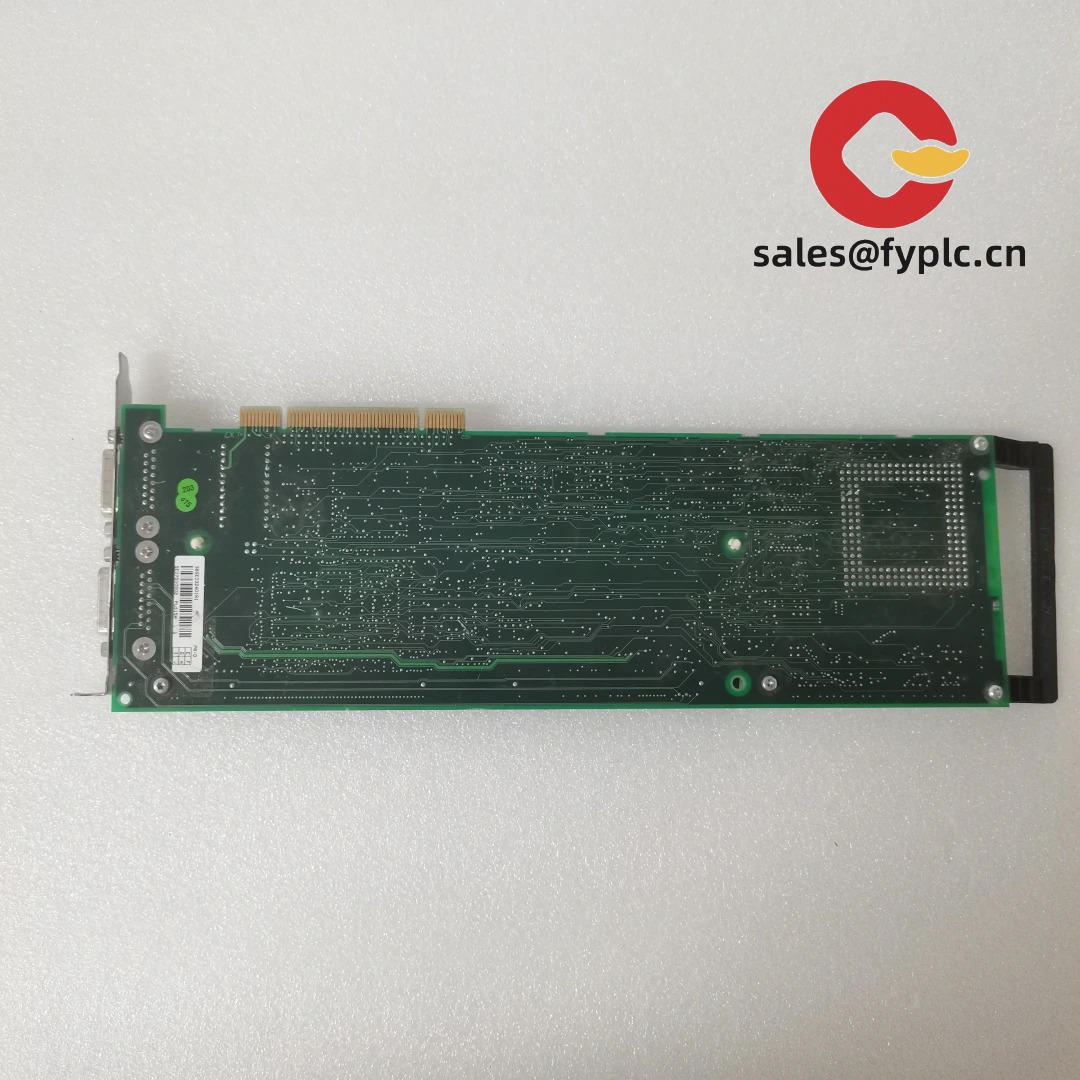

The ABB PU515A RTA Board, part number 3BSE032401R1, is a controller-internal module typically used in ABB distributed control systems to restore or extend internal real-time communication inside the CPU assembly. From my experience, engineers keep this board on hand to shorten downtime during controller maintenance, especially in plants running ABB 800xA/AC 800M-based architectures. You might notice that it doesn’t require field wiring—installation is done inside the controller housing, which tends to make swap-outs faster and less error-prone.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for ABB controller internals: Installs inside the CPU assembly; no external field wiring required.

- RTA function (controller backplane interface): Supports high-speed internal data exchange that, in many cases, is essential for stable runtime behavior.

- Backplane-powered: Draws power from the host controller—no separate power supply to manage.

- Service-friendly replacement: Swap typically takes minutes with ESD-safe handling, reducing shutdown time.

- Stable operation range: Built for industrial environments—commonly aligned to ABB controller temperature ranges.

- Traceable part number: Genuine ABB part 3BSE032401R1 for maintenance teams that require exact model matching.

Technical Specifications

| Brand / Model | ABB PU515A – RTA Board, Part No. 3BSE032401R1 |

| HS Code | 853890 (Parts for electrical control/switchgear) |

| Power Requirements | Powered via host controller backplane; no external supply |

| Operating Temperature | Typically 0 to +55 °C, aligned with ABB controller module ranges |

| Dimensions & Weight | Controller-internal board; lightweight module (generally < 0.2 kg) |

| Signal I/O Types | Internal high-speed backplane interface; no direct field I/O |

| Communication Interfaces | Internal RTA link within the controller; no user-accessible ports |

| Installation Method | Plug-in board inside the CPU housing; ESD-safe handling required |

Application Fields

In most cases, the PU515A is used for ABB DCS maintenance, spares stocking, and brownfield upgrades where controller internals need to be kept to original spec. Typical plants include:

- Chemicals and petrochemicals (continuous process control)

- Pulp & paper (machine control and drives integration)

- Power generation and utilities (boiler/turbine auxiliaries)

- Oil & gas (onshore terminals, compressor stations)

- Metals and mining (mill automation, material handling)

- Water & wastewater (plant-wide DCS and SCADA bridges)

Advantages & Value for Procurement

- Exact part matching: 3BSE032401R1 helps avoid compatibility risks during urgent maintenance.

- Reduced downtime: No external cabling—swap is typically quick with standard ESD procedures.

- System integrity: Keeps controller internals within ABB design parameters; fewer unknowns after replacement.

- Cost control: Extends life of existing ABB assets without a forced controller migration.

- Technical support: We can share field notes on handling, storage, and firmware compatibility checks if needed.

Installation & Maintenance Tips

- Cabinet environment: Keep ambient within controller-rated temperature; ensure clean, dry, and adequately ventilated enclosures.

- Power down safely: De-energize the controller and follow lockout/tagout before opening the housing.

- ESD precautions: Use a grounded wrist strap and antistatic mat; handle the board by its edges.

- Connector care: Inspect backplane connectors for dust or bent pins; do not force insertion.

- Firmware alignment: After replacement, verify controller firmware/runtime versions and perform a controlled restart as per site procedure.

- Routine checks: Periodically verify cabinet filters and cleanliness; re-seat connectors during scheduled shutdowns if communication anomalies appear.

- Storage: Keep spares in original ESD packaging, 5–30 °C, non-condensing humidity.

Quality & Certifications

- CE conformity (industrial environment)

- UL recognition (where applicable for the controller assembly)

- RoHS-compliant component materials

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days from shipment

Compatible and Supporting Components (commonly paired)

- ABB controller CPUs in the same family as the PU-series (e.g., used within ABB 800xA/AC 800M environments)

- ABB communication modules such as CI854A (PROFIBUS DP) when part of the overall system

- S800 I/O terminal bases and modules for field expansion, where relevant to the controller

One thing I appreciate is how this board helps teams keep legacy ABB nodes productive without introducing new wiring or topology changes. A maintenance engineer at a paper mill told us the swap “felt like a straightforward controller service task—no surprises, which is exactly what we want on a Friday night call-out.”

Reviews

There are no reviews yet.