Description

ABB REF542 1VCR007346 G0028 – Protection & Control Unit for Medium-Voltage Applications

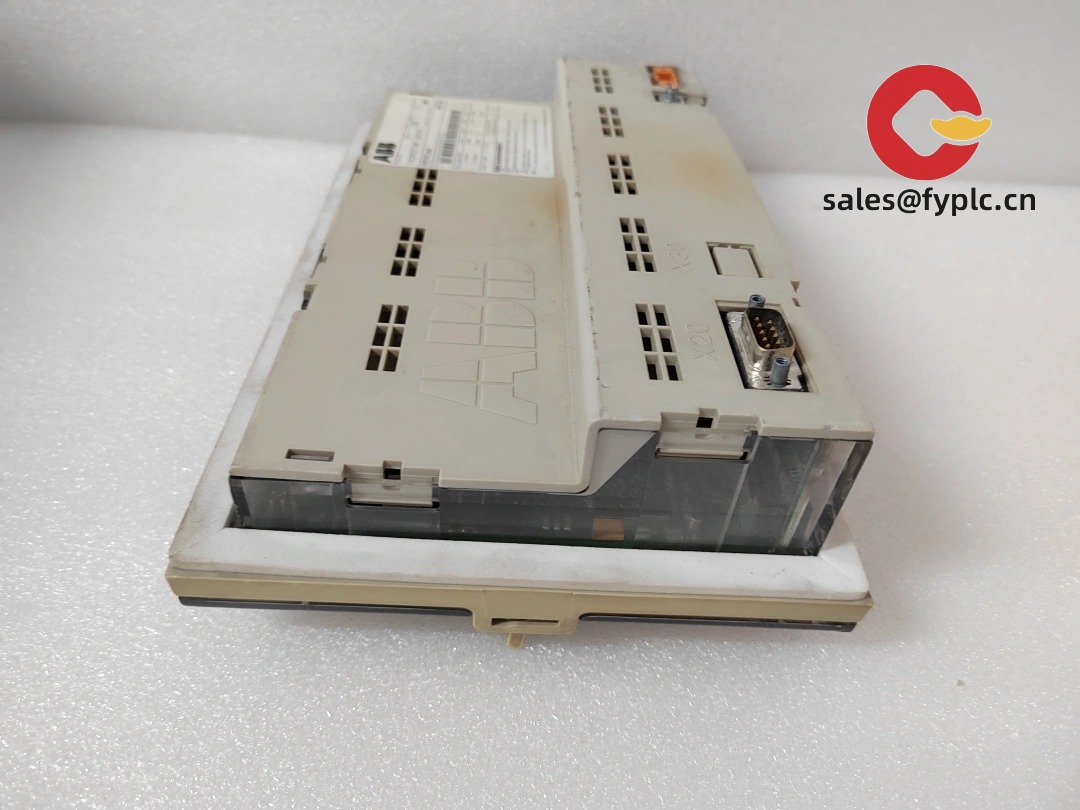

If you’re working on a substation automation upgrade or managing protection systems in industrial power networks, the ABB REF542 1VCR007346 G0028 typically shows up as a reliable choice. From my experience, it’s not just another IED—it’s built to handle both protection and control tasks in medium-voltage switchgear, which simplifies integration and reduces panel space.

Key Features

- Integrated protection and control – Combines overcurrent, earth fault, and thermal overload protection with local/remote control functions, so you don’t need separate units.

- Modular design – Allows customization of I/O modules depending on project needs; one thing I appreciate is how easy it is to adapt during retrofits.

- IEC 61850 compliance – Supports GOOSE messaging and Ethernet communication, making it compatible with modern digital substations.

- User-friendly HMI – The front panel includes a clear LCD display and intuitive navigation, which helps field engineers troubleshoot without pulling out manuals.

- Durable construction – Designed for harsh electrical environments; seems to hold up well under voltage transients and EMI noise typical in industrial plants.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / REF542 1VCR007346 G0028 |

| HS Code | 85371090 |

| Power Supply | 88–264 V AC/DC (wide-range input) |

| Dimensions (H×W×D) | 130 × 185 × 140 mm |

| Weight | Approx. 1.8 kg |

| Operating Temperature | -25°C to +70°C |

| Signal Inputs | Analog: CT inputs (1A or 5A); Digital: 12 binary inputs (wet/dry configurable) |

| Outputs | 6 relay outputs (including one alarm), programmable trip/logic functions |

| Communication Interfaces | RS-485 (Modbus RTU), Ethernet (IEC 61850-8-1, GOOSE) |

| Installation Method | Panel-mounted (standard 19” subrack or direct cubicle integration) |

Application Fields

This unit tends to show up in utility distribution networks and industrial facilities—think cement plants, mining operations, or water treatment stations where medium-voltage motors and feeders need reliable protection. In many cases, it’s used to replace older electromechanical relays while keeping existing switchgear enclosures. One customer mentioned using it in a retrofitted ring main unit where space was tight—the compact size made all the difference.

Advantages & Value

Procurement teams often favor this model because it reduces long-term maintenance costs. Since it supports standard protocols like IEC 61850 and Modbus, integration with SCADA systems is smoother than with proprietary alternatives. You might notice that spare part logistics are simpler too—ABB keeps these in production across multiple regions. And if your team already uses PCM600 for configuration, setup time drops significantly.

Installation & Maintenance

Install in a clean, dry cabinet with adequate ventilation—ideally meeting IP54 standards when mounted externally. Make sure DC supply ripple doesn’t exceed 5%, especially in older substations. Wiring should follow segregated routing practices: high-current and signal cables separated to minimize interference. For maintenance, we recommend checking firmware versions annually and recalibrating current inputs every 2–3 years, depending on operating stress. Field updates via PCM600 are usually trouble-free.

Quality & Certifications

Certified to major international standards: CE marked, UL listed (through system certification), compliant with IEC 60255 series for protection relays, and RoHS directive 2011/65/EU. The device also meets environmental requirements per IEC 60068 for vibration and climatic robustness. Comes with a 365-day warranty, covering defects in materials and workmanship under normal use.

Ordering Notes:

– Delivery: 1 week for in-stock units, no more than one month at latest

– Payment: 50% advance, balance before shipment

– Shipment: Via FedEx, UPS, or DHL—tracking provided upon dispatch

Reviews

There are no reviews yet.