Description

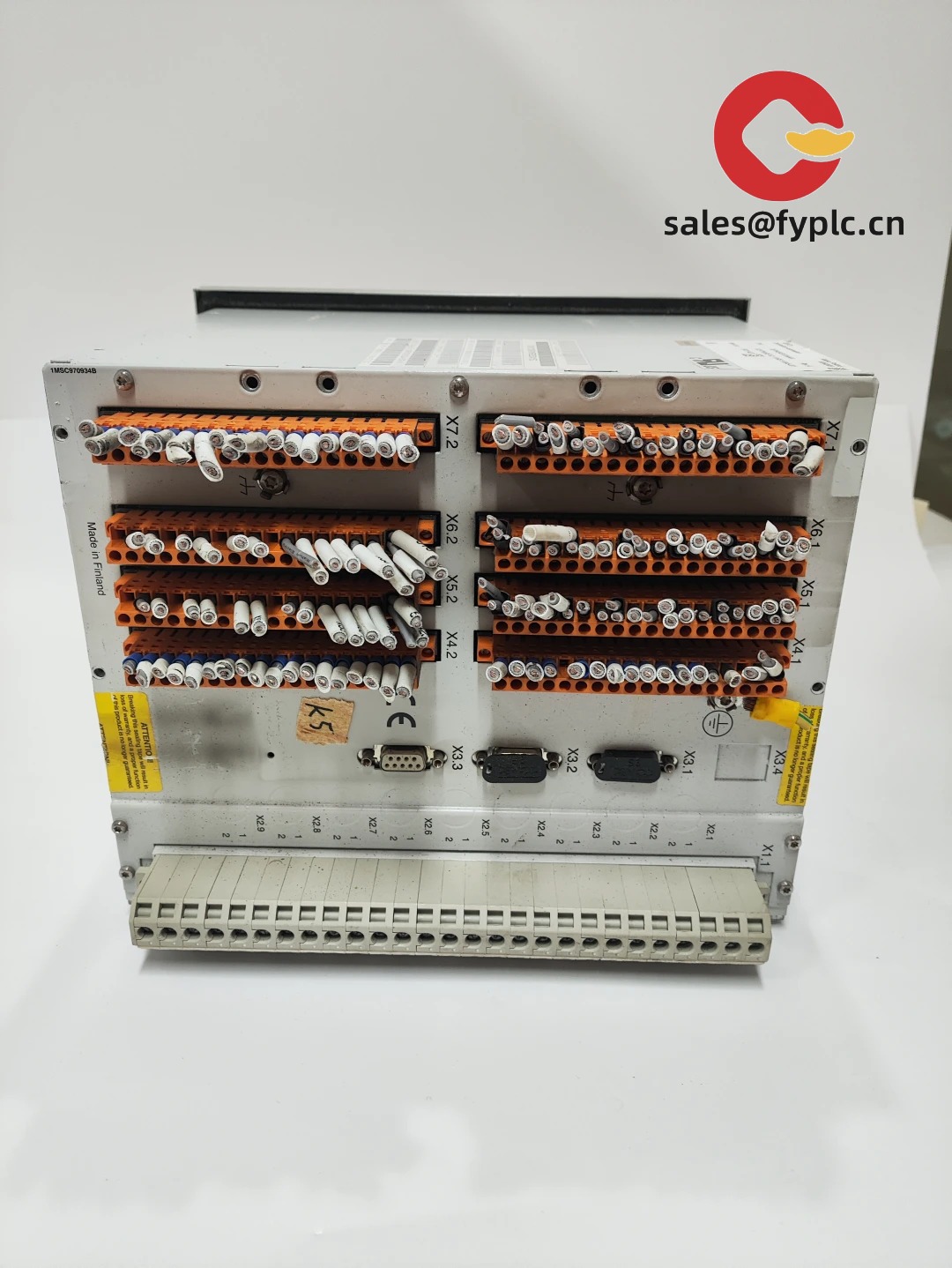

ABB REF545KB133AAAA – Feeder Protection and Bay Control for Medium-Voltage Switchgear

The ABB REF545 (REF54x platform) is a multifunction feeder protection and control terminal designed for medium-voltage networks. Model REF545KB133AAAA follows the familiar REF54x architecture with integrated bay control, comprehensive overcurrent/earth-fault protection, and a clear front-panel HMI for fast operation. From my experience, plants choose REF545 when they want dependable protection with solid interoperability to legacy SCADA—without overcomplicating day-to-day switching.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: typically 1 week if in stock; no more than 1 month latest

- Payment: 50% advance; full balance prior to delivery

- Express shipping: FedEx, UPS, DHL

- Packaging: anti-static, shock-resistant, moisture-protected for electrical equipment

Key Features

- Feeder protection suite – Typically includes phase/earth overcurrent (50/51, 50N/51N), directional earth fault (67N), thermal overload, under/overvoltage, and under/overfrequency options for MV feeders.

- Integrated bay control – Front HMI with single-line mimic, interlocking, and breaker/isolator command for safe, intuitive switching.

- Breaker failure and autoreclose – BFP and reclosing logic to improve system availability after transient faults.

- Event and disturbance records – Time-tagged events and fault records, typically exportable in COMTRADE for post-fault analysis.

- Flexible I/O – CT/VT measurement, binary inputs, and powerful output contacts to match most switchgear schemes.

- Multi-protocol communications – SPA-bus, IEC 60870‑5‑103, Modbus RTU, and LON (depending on option boards) for smooth SCADA/RTU integration.

- Reliable auxiliary supply – Wide-range AC/DC auxiliary input that fits common substation DC systems.

- Proven platform – REF54x family devices have long field history; spare parts and service know-how are broadly available.

Technical Specifications

| Brand / Model | ABB REF545KB133AAAA (REF54x feeder protection and bay control) |

| HS Code | 8536.49 (Electronic protective relays) |

| Power Requirements | Auxiliary 110–240 V AC or 110–250 V DC, 50/60 Hz (wide-range variant typical for REF545) |

| Operating Temperature | -5 to +55 °C (typical for REF54x family) |

| Signal Input Types | CT: 1 A / 5 A; VT: ~100/110 V AC nominal; Binary inputs: opto-isolated, common DC ranges (e.g., 24–250 V DC) |

| Output Types | Binary (relay) outputs, Form C contacts; typical rating up to 5 A at 250 VAC (resistive) |

| Communication Interfaces | RS‑485/RS‑232; SPA-bus, IEC 60870‑5‑103, Modbus RTU, LON (option-dependent) |

| Installation Method | Flush/panel-mounted on switchgear door; rear screw terminals; wiring per IEC 60255 practices |

Note: Exact I/O count and protocol set depend on the “KB133AAAA” optioning; we can verify against your wiring diagram before shipment.

Application Fields

- Medium-voltage feeder protection in AIS/GIS switchgear and RMUs

- Industrial power distribution (mining, metals, oil & gas, data centers, manufacturing)

- Utility distribution substations and ring networks

- Renewable integration feeders and CHP plants where reclosing and SCADA integration matter

One thing I appreciate is how the REF545 handles everyday operations—operators get a clear mimic and interlocking guidance, which in many cases reduces switching errors during busy maintenance windows.

Advantages & Value

- Reliability in service – Mature hardware with stable firmware; typically low nuisance trip rates when set correctly.

- Compatibility – Multi-protocol support eases integration with existing RTUs/PLCs and legacy SPA-bus networks.

- Lifecycle savings – Retrofitting REF54x within existing panels often minimizes re-wiring and downtime.

- Supportability – Settings and IED management tools are well known in the market, so knowledge transfer is straightforward.

A maintenance supervisor told us their crew cut fault-finding time by half after enabling disturbance recording and standardizing the I/O mapping across bays—seems to be a common win with this platform.

Installation & Maintenance

- Panel/cabinet – Mount on a rigid, grounded switchgear door with adequate ventilation; avoid high-vibration spots.

- Wiring – Use shielded twisted pairs for CT/VT secondaries and time-critical signals; verify CT polarity and burden; segregate power and communication wiring.

- Grounding – Single-point grounding of cable shields; maintain low-impedance protective earth per IEC 60255-27.

- Commissioning – Secondary injection for 50/51/67N pick-up and time checks; validate interlocks and trip circuits; document settings.

- Routine maintenance – Clean the HMI and terminals annually, check tightening torque, back up settings; update firmware where applicable and approved.

- Configuration – The REF54x family is typically engineered with ABB CAP 505; keep a controlled settings baseline for each bay.

Quality & Certifications

- Standards: Designed for protection relays to IEC 60255 series (measurement, insulation, EMC)

- Compliance: CE marked; RoHS compliance typical for the series; UL recognition may apply to certain variants

- Manufacturer quality systems: ISO 9001 production processes (typical for ABB protection devices)

- Warranty: 365-day warranty from us on this unit

If you share your one-line diagram or a picture of the existing relay terminal block, we can confirm the REF545KB133AAAA optioning (I/O map and protocol card) and pre-parameterize to shorten your outage window.

Reviews

There are no reviews yet.