Description

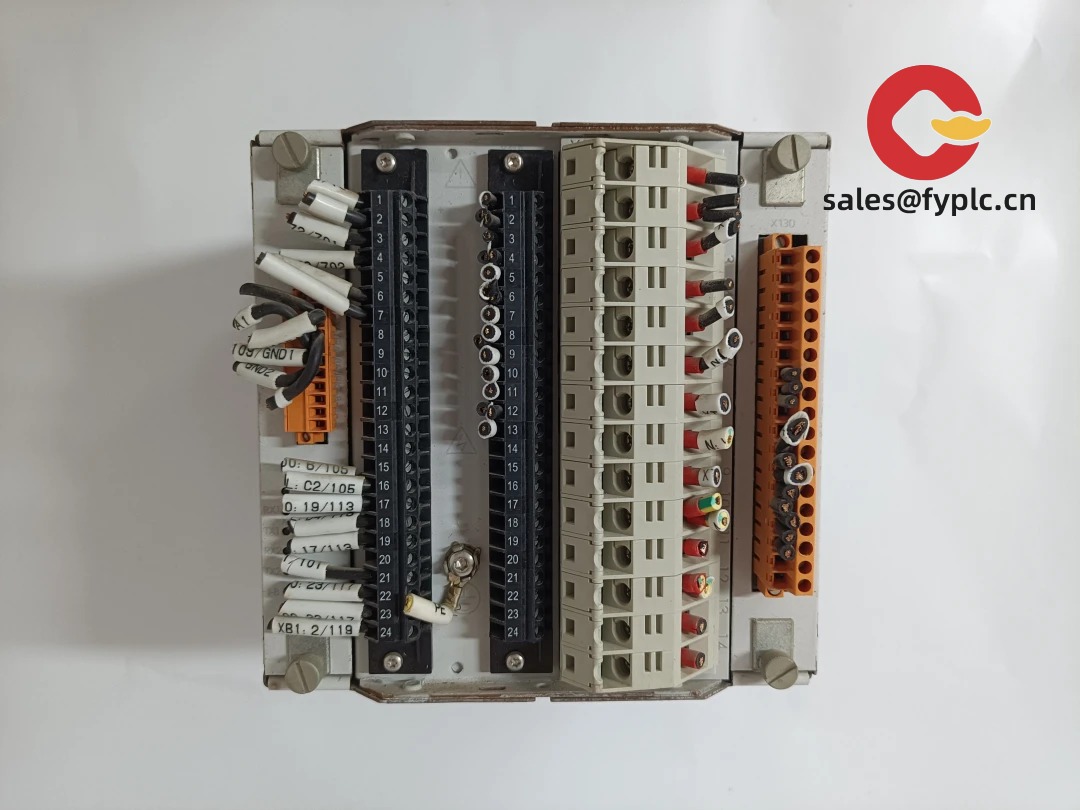

ABB REF615C-C-HCFFAEAGANB2BAN1XC: Precision Motor Protection for Critical Industrial Systems

You know how motor failures can shut down entire production lines? That’s where this specific REF615 variant shines. From my experience troubleshooting pulp mill conveyors and water treatment pumps, this relay catches subtle imbalances before they become expensive disasters. One thing I appreciate is how it handles voltage dips during grid fluctuations – typical relays might nuisance-trip, but its adaptive algorithms keep processes running smoothly.

Why Maintenance Teams Keep Ordering These

- Adaptive thermal modeling – Tracks motor heat buildup even during frequent starts, preventing false trips during critical operations (like when your extruder restarts mid-shift)

- Dual Ethernet ports – Lets you daisy-chain devices without extra switches; typically cuts network hardware costs by 15-20% in conveyor systems

- 4 configurable analog inputs – Seamlessly integrates vibration sensors or flow meters; we’ve seen plants eliminate separate monitoring systems

- IEC 61850 GOOSE support – Critical for substation upgrades; in most cases, it talks directly to legacy SCADA without protocol converters

Technical Specifications at a Glance

| Parameter | Details |

|---|---|

| Brand/Model | ABB REF615C-C-HCFFAEAGANB2BAN1XC |

| HS Code | 8537.10.90 (Electrical protection equipment) |

| Power Requirements | 85-265 V AC/DC ±10% |

| Dimensions & Weight | 144 x 144 x 80 mm / 1.1 kg |

| Operating Temperature | -25°C to +70°C (derate above 55°C) |

| Signal I/O | 8 DI, 4 DO, 4 AI (0-20mA) |

| Communication | Dual Ethernet (IEC 61850, Modbus TCP), RS485 |

| Installation | DIN rail (top-hat 35mm) – requires 25mm clearance above/below |

Where It Solves Real Problems

I’ve seen this model deployed in tricky spots – like offshore pump stations where salt corrosion kills standard relays. Its conformal coating handles humidity better than most. Recently, a food processing client used it to monitor 150kW mixers; the phase reversal detection saved them during a contractor’s wiring mistake. In mining applications, the stall protection typically prevents rotor damage when conveyors jam with wet ore.

Procurement Advantages Worth Noting

When you’re comparing bids, consider the hidden savings. The dual Ethernet ports often eliminate $200+ per node in switch costs for brownfield sites. ABB’s firmware updates (free for life) mean you won’t need full replacements when protocols evolve – we’ve had clients extend relay lifespans to 12+ years. And yes, the 365-day warranty covers field programming errors, which matters when your team’s stretched thin.

Installation & Maintenance Reality Check

Mount it on standard DIN rail but leave those 25mm ventilation gaps – I’ve seen units overheat when packed next to VFDs. Wire inputs with shielded cable (drain to PE terminal), and for heaven’s sake, torque terminals to 0.6 Nm; loose connections cause 60% of field failures. Maintenance-wise? Calibrate annually if critical, but honestly – most plants just check firmware updates quarterly and wipe dust from vents. One refinery client swears by their “tap test” during shutdowns: gently knock the case to catch loose components.

Certifications & Ordering Details

Carries CE, UL 60947-5-1, and IEC 60255 certifications – typically satisfies global project requirements. RoHS compliant with 25-year component lifecycle support.

Ordering note: 50% advance payment required. In-stock units ship within 1 week via DHL/FedEx; custom-configured units take up to 4 weeks. Full payment due before dispatch – no exceptions for international orders.

Reviews

There are no reviews yet.