Description

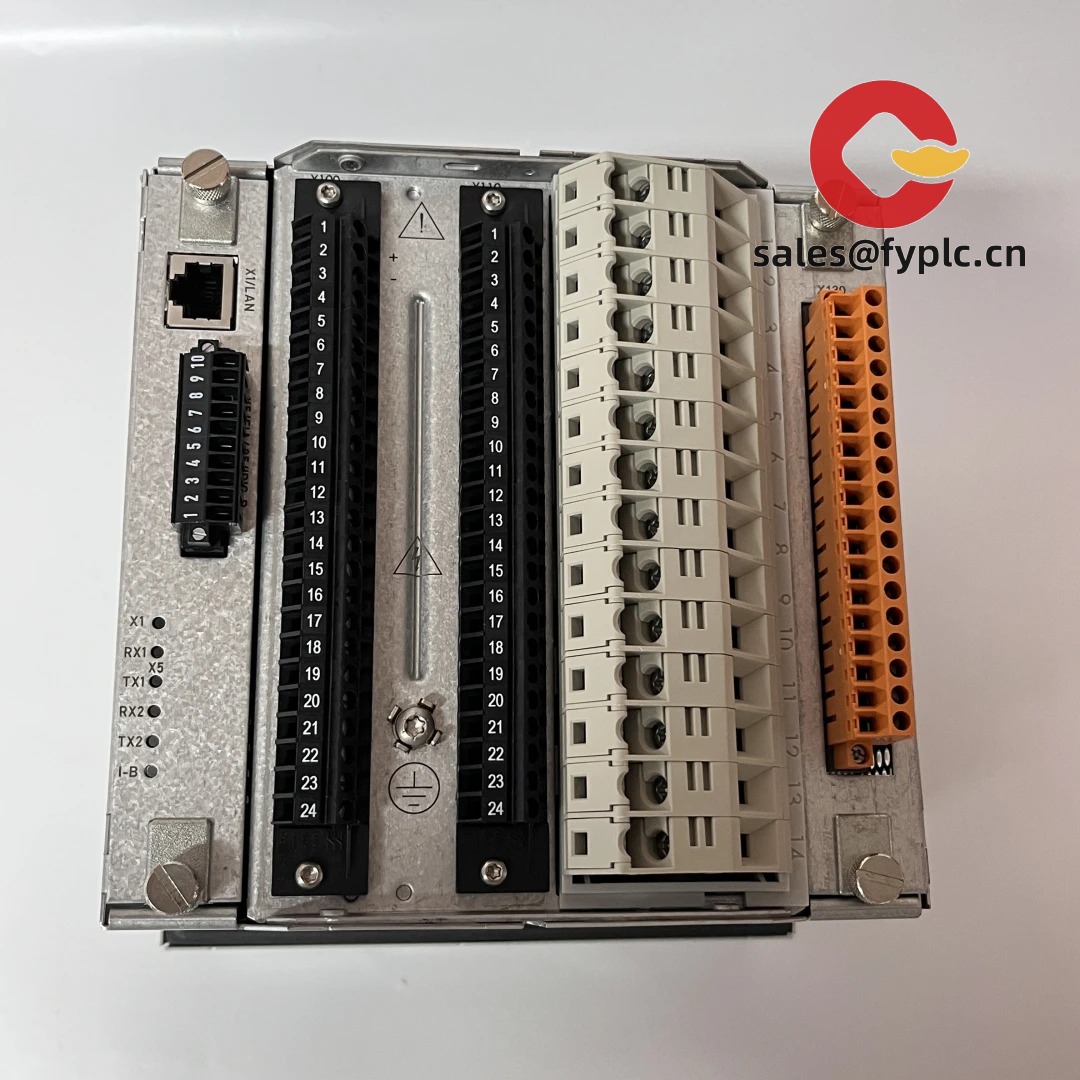

ABB REF615C-E-HCFEAEAGABC2BAA11E – Compact Feeder Protection Relay for Medium-Voltage Switchgear

The ABB REF615C-E-HCFEAEAGABC2BAA11E is part of ABB’s Relion 615 series, purpose-built for MV feeder protection and control. From my experience, it fits best in 11–33 kV distribution panels where utilities and industrial plants want rock-solid overcurrent, earth-fault and voltage/frequency functions with IEC 61850 communications baked in. You might notice that the 615 platform is widely used because commissioning is predictable and the logic tools are mature—typically that saves time when you’re standardizing bays across a substation.

Typical protection coverage includes 50/51, 50N/51N, 67/67N, 27/59, 81U/81O/81R, 79 and 50BF, plus breaker supervision and synch/check depending on the option string. The long option code on this unit indicates a factory-configured variant with Ethernet comms and a common MV feeder function set—ideal for ring main units, metal-clad switchgear, and retrofit projects.

Order Placement Process and Guarantees

-

- – Warranty period: 365 days from delivery

-

- – Delivery: typically 1 week if in stock; no more than 1 month latest

-

- – Payment terms: 50% advance payment; full balance prior to delivery

- – Express carriers: FedEx, UPS, DHL (export packing, shock-proof)

Key Features

- MV Feeder Protection Suite – Directional/non-directional overcurrent and earth-fault, voltage/frequency, autoreclose, and breaker failure for overhead lines and cable feeders.

- IEC 61850 Communications – Native Ethernet with GOOSE for fast interlocking; Modbus/DNP3 often available by order code for mixed-system plants.

- Programmable Logic – IEC 61131-style logic blocks help tailor bay functions without external relays; in many cases it removes the need for auxiliary logic relays.

- Flexible I/O and Sensor Inputs – Supports 1 A / 5 A CTs and standard VT inputs; multiple programmable binary I/O points for scheme control and status.

- Compact 615-Series Case – Designed for flush mounting in MV switchgear doors; seems to be a straightforward fit for both new panels and retrofits.

- Cybersecurity & Time Sync – Role-based access, event logs, and SNTP/IRIG-B time synchronization improve traceability during fault analysis.

- Event/Fault Records – Oscillography and disturbance records (COMTRADE) support faster troubleshooting and post-fault investigation.

Technical Specifications

| Brand / Model | ABB REF615C-E-HCFEAEAGABC2BAA11E (Relion 615 series) |

| HS Code | 85364900 (Electrical relays, other than ≤60 V) |

| Power Requirements | Aux supply typically 24–250 V DC or 100–240 V AC, 50/60 Hz; consumption ≤ 40 VA in most cases (per option) |

| Operating Temperature | -40 to +55 °C (typical for 615-series devices) |

| Signal I/O Types | CT inputs 1 A / 5 A; VT inputs (100–120 V nominal); programmable binary inputs (24–250 V DC); relay outputs (up to 250 VAC / 30 VDC) |

| Communication Interfaces | Ethernet 100BASE‑TX (RJ45) with IEC 61850; Modbus TCP/DNP3 via option set; time sync via SNTP/IRIG‑B (where fitted) |

| Installation Method | Flush/semiflush panel mounting in MV switchgear; rear terminal blocks; grounding per IEC 60255 |

| Dimensions & Weight | Compact 615-series case; typically ~177 × 177 × 160 mm (H×W×D); ~2.8 kg |

Application Fields

- Utility distribution feeders (overhead and cable) at 6–35 kV substations

- Industrial MV switchboards in mining, metals, oil & gas, data centers, and chemicals

- Ring Main Units (RMUs) and compact secondary substations

- Feeder bays with fast transfer, automatic reclose, and interlocking over IEC 61850 GOOSE

- Retrofit projects replacing legacy electromechanical or early numeric relays

Advantages & Value for Procurement

- Reliability – Field-proven 615 platform with robust self-supervision and disturbance recording. In many cases, this translates into fewer nuisance trips and faster fault isolation.

- Compatibility – IEC 61850 as standard and optional Modbus/DNP3 make integration with existing SCADA and PLC systems quite straightforward.

- Lifecycle Cost – Standardized hardware and firmware reduce spare holdings and training overhead. Typical commissioning is consistent across bays.

- Support & Tools – Widely available configuration tools and documentation; settings management and cloning simplify rollouts across multiple substations.

Real-world feedback: a regional utility standardized 20 panels on REF615 and cut commissioning time by roughly 25% because the logic templates and communication mappings were repeatable across sites. That seems to be the sweet spot of the 615 family.

Installation & Maintenance

- Panel/Cabinet – Install in clean, dry switchgear panels with adequate ventilation. Maintain clearance for cable bends and heat dissipation.

- Wiring – Use shielded twisted pairs for binary I/O and Ethernet as required. CT/VT wiring should follow polarity and burden limits; short the CTs during service.

- Grounding – Bond the relay case to the protective earth; follow IEC 60255 EMC practices to minimize induced noise.

- Settings & Testing – Upload settings via the vendor tool, verify interlocks with GOOSE simulation, and perform primary/secondary injection before energization.

- Routine Care – Back up settings/event logs, inspect terminals annually, clean the HMI and ventilation paths, and apply firmware updates during planned outages when applicable.

Quality & Certifications

- Conformity: CE marking; UL/cUL listing typically available for 615-series

- Standards: Designed to IEC 60255 (protection relays), IEC 61850 (communications), and relevant EMC/EMI directives

- Environmental: RoHS compliant; manufactured under ISO 9001 quality systems

- Warranty: 365 days (replacement or repair as per terms)

Recommended Accessories & Supporting Components

- ABB RTXP 18 test switch – for safe secondary injection and isolation during maintenance

- RJ45 industrial Ethernet patch cords or fiber media converters (if fiber segment is needed)

- Auxiliary CTs/VTs matched to protection settings where legacy instrument transformers are not within burden limits

- Label kits and terminal markers for faster bay-by-bay commissioning

Reviews

There are no reviews yet.