Description

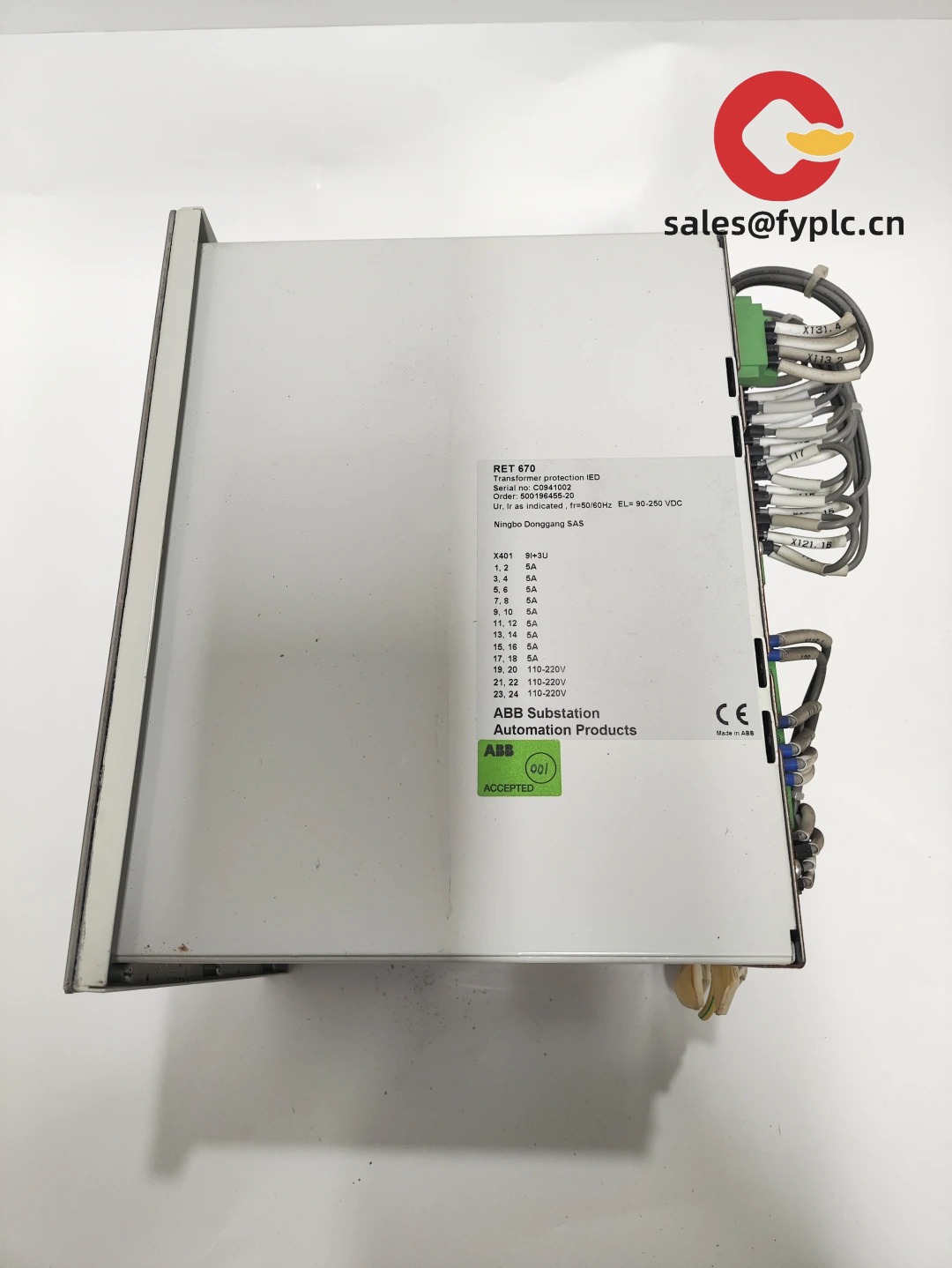

ABB RET670-1MRK002816-AB – High‑end Transformer Protection and Control IED for 2/3‑winding and Autotransformers

The ABB Relion RET670-1MRK002816-AB sits in ABB’s flagship 670 series and is typically used as the main differential protection and bay control for critical power transformers. From my experience, this variant is chosen when utilities need dependable transformer differential (87T) with fast backup functions, strong IEC 61850 performance, and clean integration into modern substation automation. You might notice that it’s not only about protection speed—the device also streamlines bay control, event recording, and time sync so commissioning is faster and fewer boxes are needed in the panel.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

- Order flow: Confirm model and configuration → Proforma invoice → Advance payment → Functional testing and packing → Balance payment → Express shipment with tracking

Key Features

- Transformer Differential (87T) with high stability – Multi‑slope restraint and second‑harmonic/inrush blocking help avoid false trips during energization, even with CT saturation.

- Comprehensive backup protection – Time/grading overcurrent, earth‑fault, over/under‑voltage, frequency, negative‑sequence and thermal overload functions typically included for robust redundancy.

- REF and winding‑specific protection – Restricted earth fault, neutral voltage displacement, and dedicated winding logic for 2‑ or 3‑winding and autotransformer schemes.

- On‑load tap‑changer (OLTC) supervision and control – Supports voltage regulation, tap position monitoring, and alarm logic; practical when the bay controller is consolidated into the relay.

- IEC 61850 Ed.2 with GOOSE/SMV – Process and station bus ready; PRP/HSR redundancy is available in many builds for zero‑time recovery networking.

- Extensive disturbance and event recording – Fault records, oscillography and sequence of events make post‑fault analysis faster and clearer.

- Time synchronization – SNTP native; many configurations support IRIG‑B or IEEE 1588 PTP for tight time stamping.

- Flexible I/O and CT/VT inputs – 1 A/5 A CTs and standard VT inputs, plus configurable binary I/O for interlocking and tripping logic.

- Cybersecurity and user management – Role‑based access, logging, and settings handling designed to align with utility cyber practices.

- Rugged substation design – Typically operates from −25°C to +55°C; meets IEC 60255 environmental and EMC standards in most cases.

Technical Specifications

| Brand / Model | ABB RET670-1MRK002816-AB (Relion 670 series) |

| HS Code | 8536.49 (Electrical relays, other) |

| Power Requirements | 24–250 V DC or 48–250 V AC (depending on power supply module; single or redundant supply options) |

| Dimensions & Weight | 19‑inch rack/panel flush case, approx. 4U height; weight varies by I/O build (typically 6–8 kg) |

| Operating Temperature | −25°C to +55°C (typical operation), short‑time up to +70°C depending on configuration |

| Signal I/O Types | CT inputs 1 A / 5 A; VT inputs (typically 100 V); binary inputs 24–250 V DC; high‑speed trip and alarm outputs |

| Communication Interfaces | IEC 61850 Ed.2 (GOOSE/SMV), 100Base‑TX/FX Ethernet; PRP/HSR redundancy in many builds; optional IEC 60870‑5‑103 / DNP3 / Modbus; front maintenance port |

| Time Synchronization | SNTP; IRIG‑B or IEEE 1588 PTP available depending on ordered variant |

| Installation Method | Panel flush or 19‑inch rack mounting; plug‑in terminal blocks for CT/VT, I/O and comms |

Application Fields

The RET670 is typically deployed as Main 1 or Main 2 protection in transmission and sub‑transmission transformer bays. It suits:

- 2‑winding and 3‑winding power transformers in AIS or GIS substations

- Autotransformers and generator step‑up (GSU) transformers

- Industrial utility systems where tight selectivity and fast differential protection are needed

- Projects transitioning to digital substation architectures (IEC 61850 process bus, SMV/GOOSE)

Advantages & Value

- Reliability that reduces risk – Proven 87T algorithms with inrush restraint and transient‑stable logic mean fewer nuisance trips and less downtime.

- Lifecycle flexibility – Modular I/O and protocol options help the device stay compatible as stations evolve; you typically avoid rip‑and‑replace.

- Reduced panel footprint – Combining protection and bay control can eliminate separate controllers and save wiring and cabinet space.

- Integration cost savings – Native IEC 61850 Ed.2 with PRP/HSR seems to cut engineering hours on redundant network designs.

- Technical support and spares – Widely adopted platform, so training, firmware, and replacement modules are easier to source in most regions.

Installation & Maintenance

- Panel and wiring – Install in a clean, dry cabinet (19‑inch rack or flush). Provide front clearance for HMI and rear clearance for CT/VT and Ethernet. Keep CT/VT leads short and tightly twisted; earth the CT secondary correctly.

- Power and grounding – Use the specified AC/DC supply range for the ordered power module; consider dual supplies for redundancy. Bond the case to the station earth bar with low‑impedance connections.

- Networking – For PRP/HSR, segregate A/B LANs; label ports clearly. Verify IEC 61850 datasets, GOOSE subscriptions and time sync before energization.

- Commissioning – Primary/secondary injection for 87T and REF; check slope/restraint settings and CT ratios; verify trip circuits and interlocks. Keep disturbance recorder enabled during initial energization.

- Routine maintenance – Annual settings review and relay self‑test logs; clean ventilation slots; verify time sync; apply vetted firmware updates during planned outages. Periodic calibration checks for analog channels are recommended.

- Safety – Isolate trip circuits before testing. Never open CT circuits under load. Follow site LOTO and arc‑flash procedures.

Quality & Certifications

- Designed and tested to IEC 60255 (protection relays and associated equipment)

- IEC 61850 Ed.2 interoperability (conformance tested on 670 family variants)

- CE marking; RoHS compliance; manufacturing under ISO 9001 quality systems

- Typical utility approvals available by region; UL/cUL conformity may depend on the exact build

- Manufacturer’s warranty is typically available; we provide 365‑day warranty on supply

A quick note from a recent customer: “We swapped a legacy transformer relay for RET670 and kept the existing CT/VT ratios. The differential stabilized immediately on energization, and GOOSE interlocking cut our copper by a lot. Commissioning was quicker than expected.” That matches what we often see on retrofit jobs—solid performance with predictable setup.

Reviews

There are no reviews yet.