Description

ABB RF522 3BSE000743R1 — High-Integrity Redundant Fieldbus Coupler for AC 800M DCS Systems

Let’s be honest—fieldbus couplers rarely get the attention they deserve until something goes sideways in a turbine control loop or a distillation column trips unexpectedly. The ABB RF522 (3BSE000743R1) is one of those unassuming but mission-critical modules that quietly keeps your AC 800M DCS running with redundancy baked in—not as an afterthought, but as core architecture. From my experience supporting brownfield upgrades in pulp & paper and offshore oil & gas plants, this unit shows up most often where uptime isn’t just preferred—it’s contractually mandated.

Key Features

- True hardware redundancy: Dual PROFIBUS DP-V1 masters on separate ASICs—so if one fails, the other takes over in under 100 ms, no reinitialization needed. One thing I appreciate is how cleanly it integrates with AC 800M’s built-in redundancy logic; no custom scripting required.

- Hot-swappable design: You can replace it mid-operation without shutting down the controller rack—critical during scheduled maintenance windows when process continuity matters more than convenience.

- Integrated diagnostics & LED status matrix: Real-time visibility into bus health, slave response times, and CRC error rates. A customer in Rotterdam told me they cut fieldbus troubleshooting time by ~40% just by watching the blinking pattern before even opening Control Builder.

- EMC-hardened for industrial environments: Rated for 2.5 kV surge immunity and operates reliably near VFDs or high-current switchgear—something you’ll notice matters most in retrofit installations where cable routing wasn’t originally optimized.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB RF522 / 3BSE000743R1 |

| HS Code | 8537.10.90 (Control panels for industrial automation systems) |

| Power Requirements | 24 V DC ±15%, max. 1.2 A (per channel); powered via AC 800M backplane |

| Dimensions & Weight | 125 × 112 × 120 mm (W × H × D), approx. 1.1 kg |

| Operating Temperature | 0 °C to +60 °C (derated above +45 °C for continuous operation) |

| Signal Input/Output | Dual isolated PROFIBUS DP-V1 master ports (9-pin D-sub, RS-485 physical layer) |

| Communication Interfaces | Backplane interface to AC 800M controller (via S800 I/O link); no external Ethernet or serial ports |

| Installation Method | DIN-rail mounted in ABB S800-compatible cabinets; requires AC 800M controller rack (e.g., PM866, PM891) |

Application Fields

This module typically appears in safety- and availability-sensitive applications: turbine/generator control in combined-cycle power plants, burner management systems in refineries, or batch sequencing in pharmaceutical cleanrooms. It’s not usually deployed in standalone PLC setups—its value shines when tied into ABB’s full AC 800M ecosystem, especially where PROFIBUS-connected motor starters, valve positioners, or weighing terminals need deterministic cycle times and fault containment. In many cases, engineers choose it specifically to avoid “single-point-of-failure” architectures—even if their current bus load doesn’t yet justify redundancy, they’re future-proofing against unplanned expansion.

Advantages & Value

If you’re evaluating procurement options, here’s what tends to tip the scale: First, compatibility isn’t theoretical—it’s validated down to firmware revision level. You won’t waste days chasing version mismatches between Control Builder M, S800 firmware, and the coupler itself. Second, while it’s not the cheapest coupler on the market, its mean time between failures (MTBF) exceeds 200,000 hours—so total cost of ownership drops significantly in high-availability sites where spares sit idle for years, then save a $500k/day production loss. And third, ABB’s global support network means spare units are often available regionally—no waiting for air freight from Sweden when your mill’s weekend shift depends on it.

Installation & Maintenance

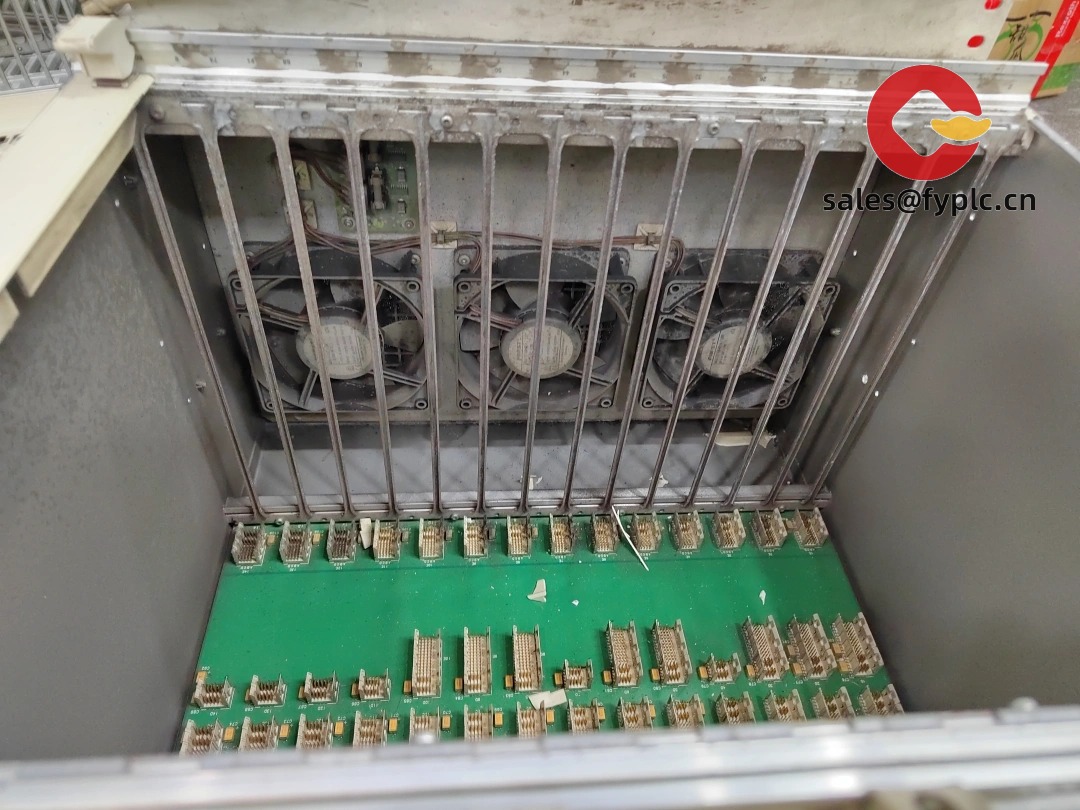

Mount only in ABB-certified cabinets meeting IP54 minimum (or higher in corrosive areas). Ensure ambient airflow around the module—don’t stack tightly beside heat-generating S800 analog input cards without spacing. Wiring must use shielded twisted-pair (STP) PROFIBUS cable with proper termination resistors (110 Ω at both ends of each segment). Avoid routing alongside 4–20 mA signal cables unless separated by ≥30 cm or grounded metal barrier. For maintenance: check LED status weekly; verify bus diagnostics monthly in System 800xA; update firmware only during planned outages—and always test redundancy failover *before* returning to service. Calibration isn’t applicable (it’s a digital interface device), but cleaning the heatsink fins every 12 months with compressed air helps sustain thermal performance.

Quality & Certifications

The RF522 carries CE (EN 61000-6-2/-4), UL 61010-1 (Industrial Control Equipment), ATEX II 2G Ex ib IIC T4 Gb (for Zone 1 installations), and RoHS 2015/863 compliance. It’s manufactured under ISO 9001:2015 and ISO 14001:2015 at ABB’s facility in Västerås, Sweden. Warranty is 365 days from date of shipment—standard across ABB’s S800 product line. We stock this model regularly; delivery is typically within 1 week if in stock, or no more than 30 days for special-order builds. Payment terms: 50% advance, balance before dispatch. We ship globally via FedEx, UPS, or DHL—with real-time tracking and insurance included.

Reviews

There are no reviews yet.