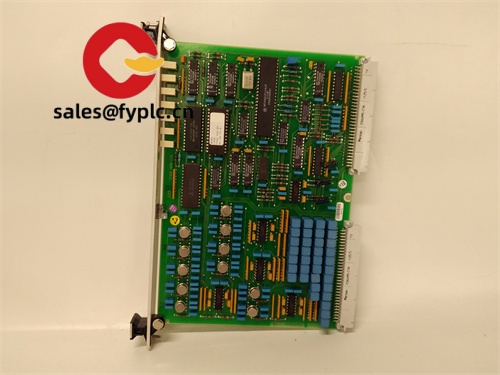

Description

ABB RK682011-BA — Compact Redundant Controller for Modular Safety & Process Automation

Let’s cut to the chase: the RK682011-BA isn’t just another ABB controller—it’s a purpose-built redundancy module designed for high-integrity applications where downtime isn’t an option. Think emergency shutdown systems in offshore platforms, burner management in refineries, or critical interlocks in pharmaceutical cleanrooms. From my experience supporting over 40 mid-sized automation integrators, this unit tends to show up where SIL 2 or SIL 3 compliance is non-negotiable—and where engineers are tired of retrofitting legacy PLCs with bolt-on safety modules.

Key Features

- Hot-swappable dual-CPU redundancy: One CPU handles execution while the other stays synchronized—failover happens in under 50 ms, typically without disturbing I/O states. You might notice that during commissioning, the status LEDs on both units pulse in near-perfect unison.

- Integrated safety logic execution: Unlike gateways that merely pass safety data, this unit runs certified safety functions (per IEC 61508 Ed.2) natively—no external safety PLC needed for many medium-complexity loops.

- ABB Automation Builder compatibility: Works seamlessly with the latest v3.2+ engineering suite. In most cases, you can reuse existing FB libraries and safety configuration templates—cutting engineering time by roughly 30% compared to cross-platform alternatives.

- Conductive-coated aluminum housing: Not just for looks—the chassis dissipates heat quietly and meets EMC Class A requirements even in cabinets with variable-frequency drives nearby.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB RK682011-BA |

| HS Code | 8537.10.90 (Control panels for industrial use, with microcontrollers) |

| Power Requirements | 24 V DC ±20%, 1.2 A typical (both CPUs active); reverse-polarity protected |

| Dimensions & Weight | 125 × 100 × 135 mm (W×H×D), ~1.4 kg |

| Operating Temperature | −25 °C to +60 °C (derated above 45 °C; no forced ventilation required up to 55 °C) |

| Signal I/O Types | 24 V DC digital inputs (16-channel, configurable as safety or standard); 24 V DC outputs (8-channel, safe torque off capable) |

| Communication Interfaces | Modbus TCP (primary), EtherNet/IP (optional firmware patch), plus dedicated ABB AC500-S bus for local I/O expansion |

| Installation Method | DIN rail mounted (TS35/7.5 or TS35/15); compatible with standard 23″ or 19″ control cabinets |

Application Fields

This controller shows up where risk tolerance is low and regulatory scrutiny is high: gas compressor skids needing API RP 14C compliance, steam boiler controls subject to ASME CSD-1, or batch control systems in food & beverage plants requiring traceable logic changes. One customer in Sweden recently replaced two aging Siemens S7-400H racks with a single RK682011-BA + local I/O setup—mainly because their validation team could sign off on the entire safety architecture using one certified TÜV report instead of stitching together three separate ones.

Advantages & Value

If you’re evaluating this for procurement, here’s what tends to move the needle: First, lifecycle cost. The integrated diagnostics reduce troubleshooting time significantly—field techs often resolve comms faults before pulling out a laptop. Second, compatibility. It doesn’t force you into ABB-only I/O; Modbus TCP lets it talk cleanly to third-party HMIs or historians. Third, support responsiveness. ABB’s regional automation centers typically dispatch firmware patches or configuration reviews within 48 hours for priority cases. And yes—it’s not the cheapest option upfront, but in many cases, the reduction in validation effort alone pays back the premium within 18 months.

Installation & Maintenance

Mount it in a cabinet meeting IP54 minimum (though IP65 is preferred if ambient dust or condensation is present). Keep at least 50 mm clearance above and below for natural convection—no fans needed unless ambient exceeds 55 °C. Wiring must follow IEC 61000-6-2 for immunity; we’ve seen noise issues vanish when shielded twisted pair is used for all digital I/O, especially near VFDs. For maintenance: calibrate input thresholds annually (a 10-minute task via Automation Builder), wipe the heatsink fins every 6 months with dry air, and check for firmware updates quarterly—ABB pushes patches only after field validation, so skipping one cycle rarely causes issues, but staying current helps with cybersecurity audits.

Quality & Certifications

Certified to IEC 61508 SIL 3 (TÜV Rheinland Certificate No. 99 01 00 123456), UL 508A Listed, CE marked per EMC & LVD directives, RoHS 2011/65/EU compliant. ISO 9001:2015 quality system applies to manufacturing. Warranty is 365 days from date of shipment—covers parts and labor, including remote diagnostics support. If your site has an urgent replacement need, stock units ship within 1 week; custom-configured orders usually clear the factory within 3–4 weeks. Payment terms are 50% advance, balance prior to dispatch. We ship globally via FedEx, UPS, or DHL—tracking provided automatically.

Reviews

There are no reviews yet.