Description

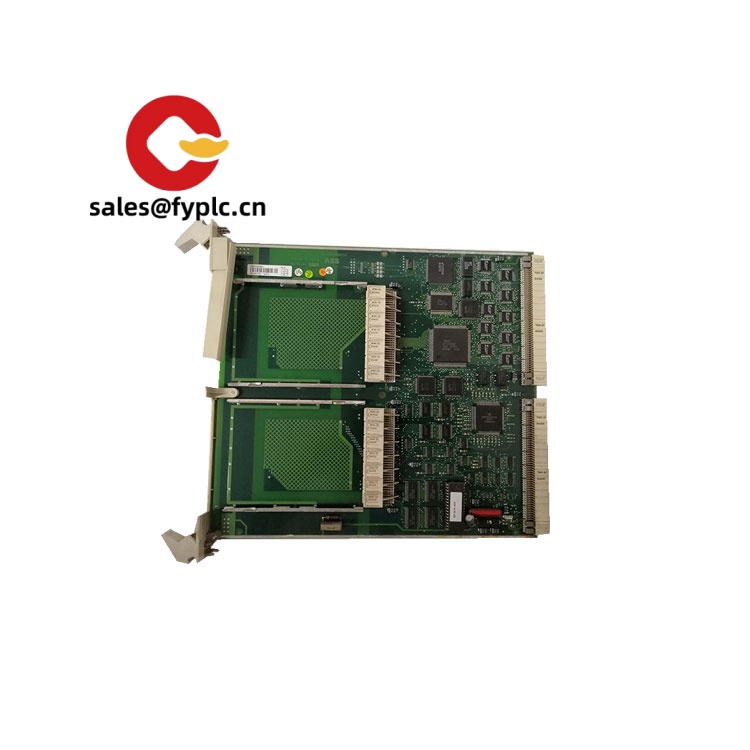

ABB S-076N (3BHB009884R0021) – Gate Driver/Power Electronics Module for ABB High-Power Drives

The ABB S-076N, part number 3BHB009884R0021, is a factory-grade gate driver/power electronics module used in ABB high-power drive systems. From my experience, this module is typically deployed in IGBT-based drive stacks (such as ACS-series frames) to provide reliable, isolated gate control and protection. If you’re maintaining an existing installation, it’s a straight, form-fit-function replacement that helps reduce downtime and troubleshooting risk.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: in-stock items ship in 1 week; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Testing: Each unit is visually inspected and function-checked before dispatch, which, in many cases, avoids commissioning surprises.

Key Features

- Form, fit, function replacement – Designed as a direct swap for S-076N assemblies with code 3BHB009884R0021, minimizing panel rework.

- Isolated gate drive – Typically provides galvanic isolation between control logic and power semiconductors for safety and noise immunity.

- Integrated protection – In many cases includes soft-shutdown and desaturation-style protection to safeguard IGBT phases during fault events.

- Stable 24 V control power – Runs from the drive’s standard auxiliary supply, simplifying cabinet wiring.

- Drive-ready interfaces – You might notice fiber‑optic links or dedicated low-voltage headers for status/trigger signals depending on the drive frame.

- Service-friendly layout – Clear connectors and fixed mounting points help speed up replacement during planned outages.

Technical Specifications

| Brand / Model | ABB S-076N – 3BHB009884R0021 |

| Product Type | Gate driver / power electronics module for ABB drive stacks |

| HS Code (reference) | 850490 (Parts for static converters; final classification may vary by country) |

| Power Requirements | 24 VDC auxiliary supply (typical for ABB drive control power) |

| Operating Temperature | Typically 0…+55 °C (cabinet ambient; follow drive manual) |

| Signal I/O Types | Fiber‑optic control links and low-voltage logic/status connectors (depending on drive frame) |

| Communication Interfaces | Internal to drive system; no external fieldbus on the module itself |

| Installation Method | Mounted inside the drive cabinet/stack; fixed screws and keyed connectors for alignment |

Application Fields

This module is commonly found in ABB high-power AC drive systems used across:

- Metals and mining – mill stands, hoists, and crushers where gate robustness matters.

- Pulp & paper – line drives and winding sections needing clean switching behavior.

- Marine & offshore – propulsion and thruster drives with strict uptime requirements.

- Oil & gas / chemicals – compressor and pump drives in controlled environments.

- Infrastructure – large HVAC fans and water treatment blowers.

One thing I appreciate is how the S‑076N format keeps integration straightforward when you’re servicing older frames; technicians often tell us the swap is quicker than expected if cable discipline is observed.

Advantages & Value

- Reliability – ABB-grade isolation and protection features help reduce nuisance trips and component stress.

- Compatibility – Built for ABB drive stacks; keeps original performance characteristics without re-engineering.

- Cost savings – Drop-in replacement limits downtime and avoids redesign or re-qualification work.

- Supportability – From my experience, parameter verification and fiber link checks are straightforward during commissioning.

Installation & Maintenance

- Environment – Install in a clean, enclosed control cabinet (IP54 or better is typical for industrial sites). Provide adequate ventilation per drive manual.

- Wiring – Use original harnessing; route fiber‑optic links and control cables away from high dI/dt busbars. Verify 24 VDC supply quality (ripple and grounding).

- Mounting – Power down, wait for DC link discharge, observe ESD precautions. Seat connectors fully before tightening the module screws to manufacturer torque.

- Safety – Lockout/tagout the upstream supply. Confirm DC bus is below safe voltage. Avoid bending fiber jumpers beyond their minimum radius.

- Routine care – Quarterly cabinet cleaning, filter replacement, connector inspection for oxidation, and a quick visual on any status LEDs. Firmware/config checks during scheduled shutdowns if your drive requires it.

Quality & Certifications

- CE marking and RoHS compliance are standard for ABB drive electronics.

- UL/CSA recognition typically applies at the drive system level; module is designed to meet the same safety regime.

- Manufactured to ABB quality standards; each supplied unit is covered by our 365‑day warranty.

Related/Supporting Components

If you’re refreshing a drive stack, consider pairing with OEM fiber‑optic links, the associated IGBT phase modules, cabinet fan filters, and a dependable 24 VDC auxiliary supply. You might notice that issues blamed on the driver often trace back to noisy 24 V rails or aged fiber jumpers—swapping these together tends to stabilize systems faster.

Reviews

There are no reviews yet.