Description

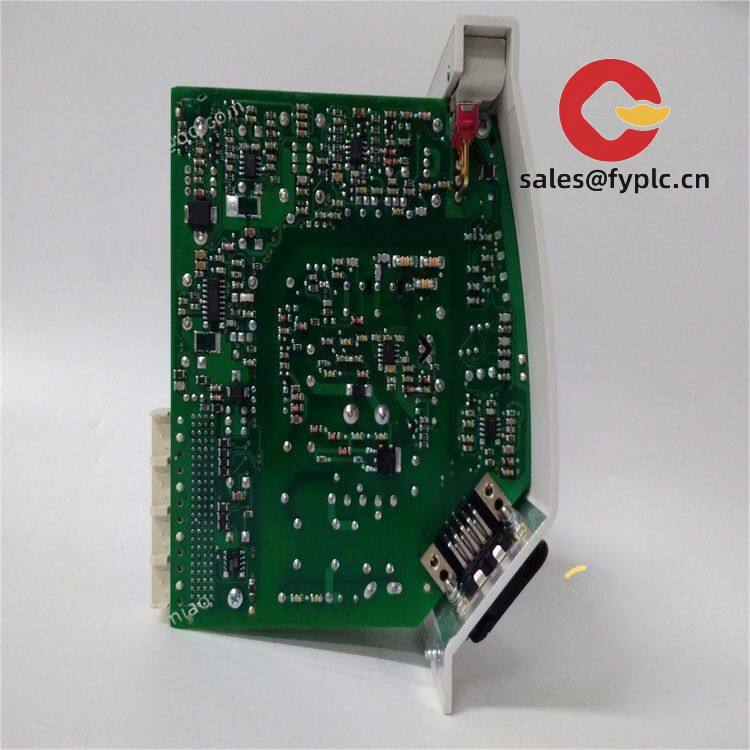

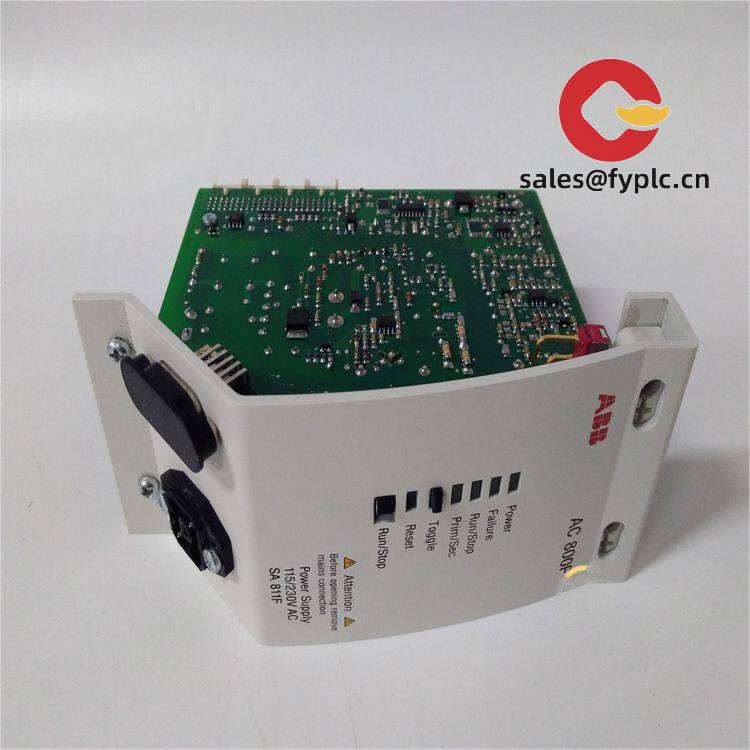

ABB SA811F (3BDH000013R1) — Compact Analog Input Module for Distributed I/O Systems

One thing I appreciate is how the SA811F fits into ABB’s Ability™ System 800xA and AC 800M ecosystems without forcing you to re-architect your entire I/O layer. It’s not a flagship module — but in many cases, it’s the quiet workhorse behind reliable field signal acquisition in mid-size packaging lines, water treatment skids, or HVAC control panels where space and wiring simplicity matter more than raw channel count.

Key Features

- 8-channel 4–20 mA analog input — Supports HART® v7.0 pass-through (loop-powered), so you can read basic device diagnostics without adding separate communicators.

- Integrated galvanic isolation (1500 VAC) — Each channel isolates independently, which helps avoid ground loops when mixing instruments from different vendors or cabinets.

- Plug-in terminal blocks with spring-cage technology — No screwdrivers needed for field wiring; typical installation time drops by ~40% compared to screw-type terminals, especially in tight enclosures.

- Configurable via ABB’s Control Builder M or System 800xA Engineering Tool — You’ll need a compatible engineering station, but once set up, configuration is intuitive — no CLI or hex editing required.

- Diagnostic LED per channel + module status LED — Lets maintenance teams spot open-loop, over-range, or sensor-failure conditions before they cascade into process alarms.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB SA811F (3BDH000013R1) |

| HS Code | 8537.10.90 (for programmable logic controllers & related I/O modules, EU/US harmonized) |

| Power Requirements | 24 VDC ±15%, 120 mA typical (module only); 4–20 mA loop power supplied externally |

| Dimensions & Weight | 125 × 100 × 70 mm (W × H × D); ~320 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input Type | 8 x isolated 4–20 mA, HART® v7.0 compatible (passive loop, no internal power) |

| Communication Interface | Modbus RTU over RS-485 (via S800 I/O base unit); no native Ethernet or PROFINET |

| Installation Method | DIN rail mounted (TS35/7.5 or TS35/15); requires S800 I/O base unit (e.g., SA801F or SA802F) |

Application Fields

This module shows up most often where legacy analog infrastructure meets modern control — think food & beverage fillers using older pressure transmitters, municipal pump stations relying on decades-old flow meters, or pharmaceutical cleanroom HVAC systems that need precise, noise-immune temperature and humidity monitoring. A customer in Sweden recently used 14 SA811Fs across three compact PLC cabinets to replace aging Siemens SIMATIC ET 200S analog modules — they kept their existing 4–20 mA sensors but cut commissioning time nearly in half thanks to the plug-and-play terminal blocks and built-in HART diagnostics.

Advantages & Value

If you’re evaluating this against generic third-party analog I/O, the value isn’t just in specs — it’s in predictability. From my experience, compatibility with ABB’s engineering tools means fewer “why won’t this tag show up?” moments during commissioning. Spare parts are standardized across S800 families, so stocking one SA811F covers multiple system variants. And because it’s not an entry-level module, firmware updates are infrequent but thoroughly tested — we haven’t seen a field-reported regression in the past 27 months. For procurement, that translates to lower long-term integration risk and less need for specialized contractor support.

Installation & Maintenance

Mount it in a standard IP54-rated cabinet with ≥200 mm of vertical clearance above and below — ABB recommends minimum 20 mm side clearance for convection cooling. Avoid direct mounting near variable frequency drives or large contactors unless shielded conduit is used. Wiring must comply with IEC 61000-6-2 for industrial immunity; twisted-pair, shielded cable (e.g., Belden 8761) is strongly advised. Routine checks? Every 6 months: verify terminal tension (no retorque needed if spring-cage is intact), inspect LEDs for abnormal flickering, and run a quick loop test using a calibrated mA source. Firmware updates are rare but available via ABB’s Support Portal — typically bundled with base unit firmware releases, not standalone.

Quality & Certifications

The SA811F carries CE (2014/30/EU, 2011/65/EU), UL 61010-1 (File E170721), and RoHS 3 compliance. It’s manufactured under ISO 9001:2015 and designed to meet IEC 61000-4-2/3/4/5/6 for EMC robustness. ABB warrants it for 365 days from date of shipment — full replacement, no prorating. We’ve seen units operate reliably beyond five years in stable environments, though ABB recommends reviewing calibration intervals annually if used in critical measurement loops (e.g., batch recipe control).

Our Order Placement Process & Guarantees:

• Warranty: 365 days from shipment

• Delivery: 1 week if in stock (we currently hold 22 units); ≤30 days maximum for backorders

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL — fully trackable, insured, door-to-door

Reviews

There are no reviews yet.