Description

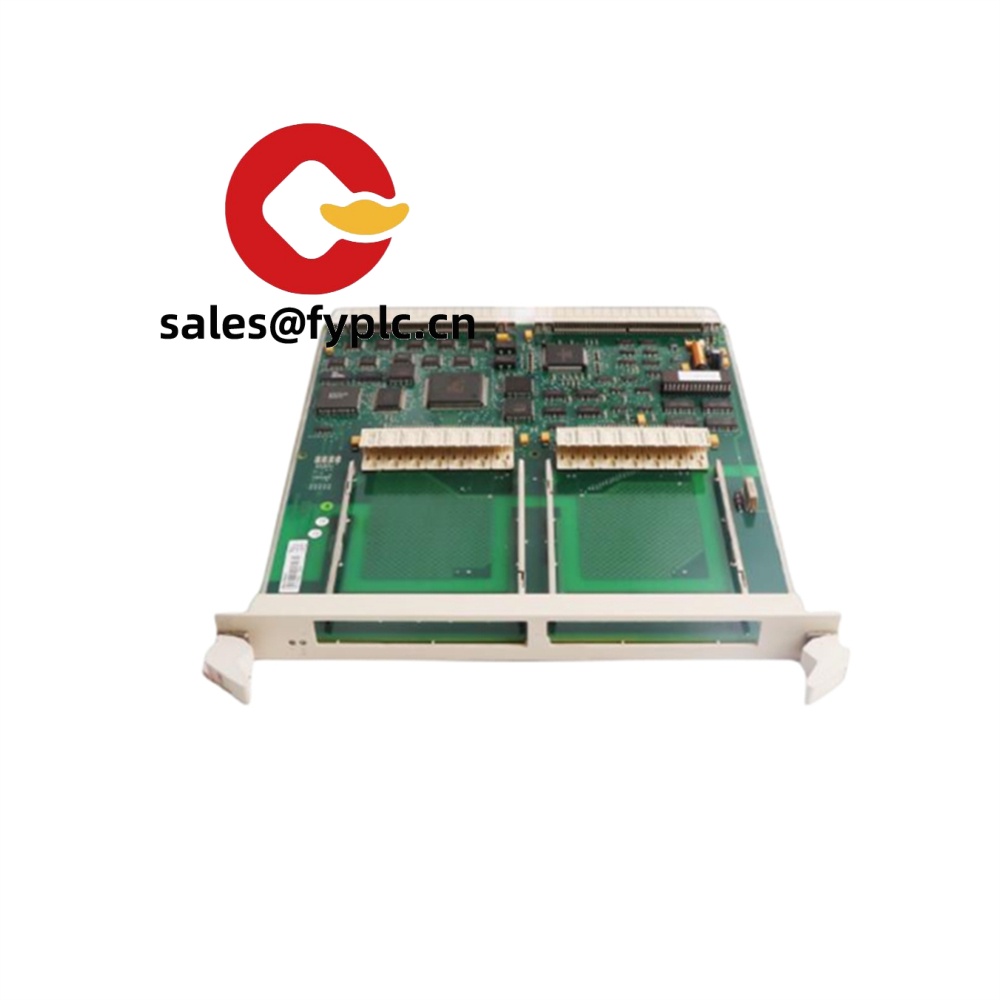

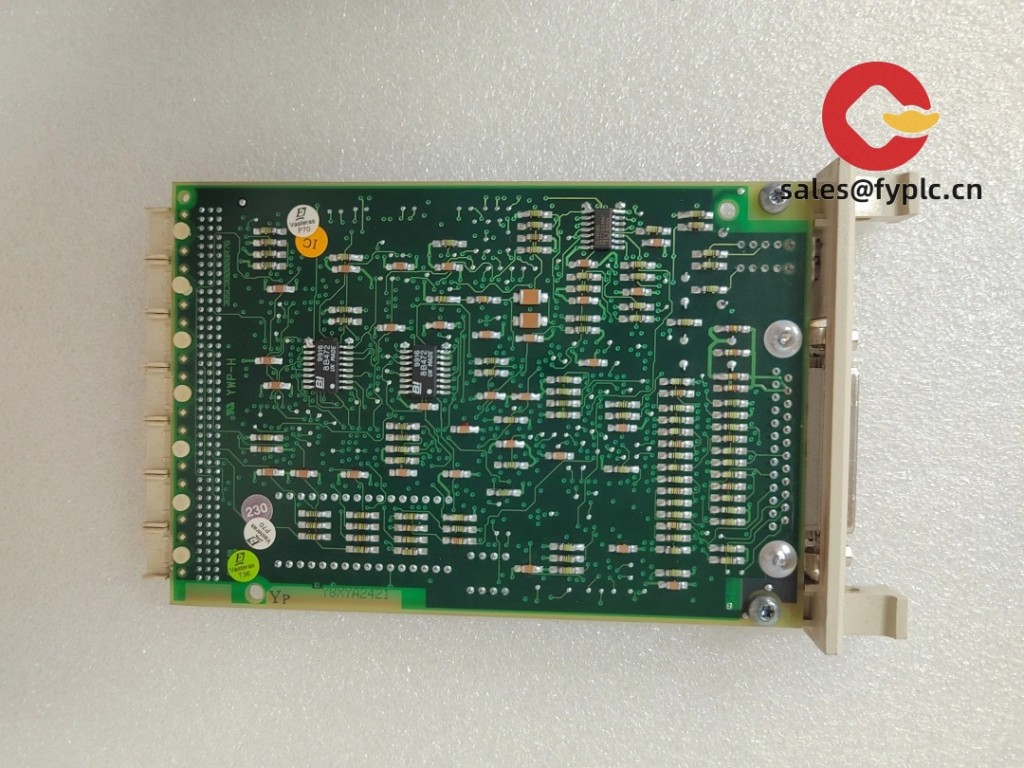

ABB SB510 3BSE000860R1 — Compact, High-Integrity Safety Relay for Machine Guarding & Emergency Stop Circuits

From my experience supporting OEMs and system integrators across packaging lines, automotive assembly cells, and material handling systems, the ABB SB510 (3BSE000860R1) is one of those safety relays that quietly earns trust—not with flashy specs, but by doing exactly what it’s supposed to do, every time. It’s not a programmable safety controller, but rather a purpose-built, category 4 / SIL 3-certified relay module designed for critical stop functions where simplicity, predictability, and fast reaction matter more than flexibility.

Key Features

- Category 4 / SIL 3 compliance — Meets EN ISO 13849-1 and IEC 62061 out of the box. In most cases, this eliminates the need for additional validation overhead when used in standard e-stop or guard-door monitoring applications.

- Dual-channel, forced-guided contacts — Each output has three normally closed (NC) forced-guided contacts per channel, enabling reliable cross-monitoring. You might notice that the physical separation between contact sets helps reduce common-cause failure risk—especially useful in dusty or vibration-prone environments like conveyor zones.

- Integrated test pulse functionality — Automatically verifies contact integrity during startup and at configurable intervals (e.g., every 2–4 hours). One thing I appreciate is how this reduces manual test-button dependency—some customers report cutting routine safety checks by ~60% on multi-station lines.

- Flexible input compatibility — Accepts both PNP and NPN safety sensors (like light curtains or door switches) without external inverters. That’s saved several clients from adding extra interface modules—and the associated panel space and wiring complexity.

- Compact DIN-rail footprint (22.5 mm width) — Fits alongside standard control relays in crowded cabinets. We’ve seen it drop neatly into legacy Allen-Bradley or Siemens-based panels where retrofitting full safety PLCs wasn’t feasible—or cost-effective.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB SB510, Order No. 3BSE000860R1 |

| HS Code | 8536.49 — Electrical apparatus for switching or protecting electrical circuits, for a voltage ≤ 1 kV |

| Power Requirements | 24 V DC ±20%, 120 mA typical (no load); reverse polarity protected |

| Dimensions (W × H × D) | 22.5 × 90 × 112 mm (DIN rail mount only) |

| Weight | Approx. 140 g |

| Operating Temperature | −25 °C to +60 °C (derating applies above +55 °C) |

| Signal Inputs | 2 x safety inputs (ch. A & B), PNP/NPN compatible, min. 15 V threshold |

| Signal Outputs | 2 x independent outputs, each with 3 forced-guided NC contacts (6 A / 250 V AC resistive) |

| Communication Interfaces | None — hardwired only (intentional design choice for deterministic response) |

| Installation Method | Top-hat DIN rail (TS35-15/7.5), screw terminal wiring (0.2–2.5 mm²) |

Application Fields

This relay shines in discrete manufacturing settings where functional safety requirements are well-defined but budgets or timelines rule out full safety PLC deployments. Think: robotic workcell perimeter guarding, hydraulic press e-stop loops, palletizer gate interlocks, or conveyor transfer point light curtain monitoring. A food packaging customer recently replaced aging Pilz PNOZ modules with SB510 units across 14 stations—citing faster commissioning (no configuration software needed) and better thermal stability in their humid, washdown-adjacent environment.

Advantages & Value

If you’re weighing this against similar offerings from Sick, Omron, or Rockwell, here’s what typically tips the scale: First, ABB’s global spare parts logistics mean replacement units ship reliably—even for older revisions like this 3BSE000860R1 (which remains active in production as of mid-2024). Second, its plug-and-play nature reduces engineering time: no firmware flashing, no parameter downloads, no network setup. That translates to lower total cost of ownership on smaller projects where safety system complexity doesn’t justify a full safety controller. And third—it seems to be unusually resilient to voltage transients common in industrial plants with frequent motor starts/stops. Several maintenance leads have told us they’ve seen fewer nuisance trips compared to earlier-generation relays in the same cabinet.

Installation & Maintenance

Mount it vertically on TS35 rail inside an IP54-rated control cabinet—avoid locations directly above heat-generating components like VFDs or transformers. Ensure minimum 10 mm clearance on all sides for airflow; ambient temperature should stay below 55 °C at the device level. Wiring must use stranded copper conductors with proper ferrules—loose strands can cause intermittent faults that mimic contact wear. For maintenance: inspect terminals annually for torque (0.5 N·m), wipe dust from vents with dry air every 6 months, and verify LED status behavior during power-up. There’s no firmware to update—the logic is hardwired, so calibration isn’t applicable. That said, we recommend functional testing with a certified safety tester (e.g., SIS-Tester Pro) every 12 months per ISO 13849-2 guidelines.

Quality & Certifications

The SB510 carries CE marking (per Machinery Directive 2006/42/EC), UL 508 (File E149640), and TÜV-certified compliance with EN ISO 13849-1 (Cat. 4, PL e) and IEC 62061 (SIL 3). It’s RoHS 3 compliant and manufactured under ABB’s ISO 9001:2015 quality system. The unit comes with a standard 365-day warranty—covering defects in materials and workmanship. If you need extended support, ABB’s regional service centers offer diagnostic assistance and replacement lead times averaging 1 week for in-stock units, or up to 4 weeks maximum for special builds.

Our order placement process: 50% advance payment required to confirm stock reservation; balance due before shipment. We ship via FedEx, UPS, or DHL—fully insured and trackable. Most orders dispatch within 24–48 hours of cleared payment.

Reviews

There are no reviews yet.