Description

ABB SB512 — Compact Safety Relay for Dual-Channel Emergency Stop & Guard Monitoring

One thing I appreciate is how the SB512 fits into tight control cabinets without sacrificing functionality—it’s ABB’s go-to safety relay for mid-complexity machines where you need certified SIL 3 / PL e performance but don’t want to over-engineer with a full safety PLC. From my experience supporting packaging lines and CNC tool changers, this unit consistently handles stop-category 0/1 logic, light curtain muting, and door guard interlocking—no external logic required.

Key Features

- Pre-configured safety functions: Built-in logic for E-stop monitoring (dual-channel), safety door switches, and reset latch—no programming needed. You might notice that even first-time users get it wired and running in under 20 minutes.

- Diagnostic LED feedback: Clear per-channel status (OK, fault, short-circuit, open-circuit) plus a dedicated “Safety Output Active” indicator—cuts troubleshooting time by half compared to older relays without visual diagnostics.

- Flexible input compatibility: Accepts standard 24 VDC safety sensors (EN ISO 13850 compliant), including mechanical switches, magnetic reed units, and semiconductor-based guards—no external voltage converters needed in most cases.

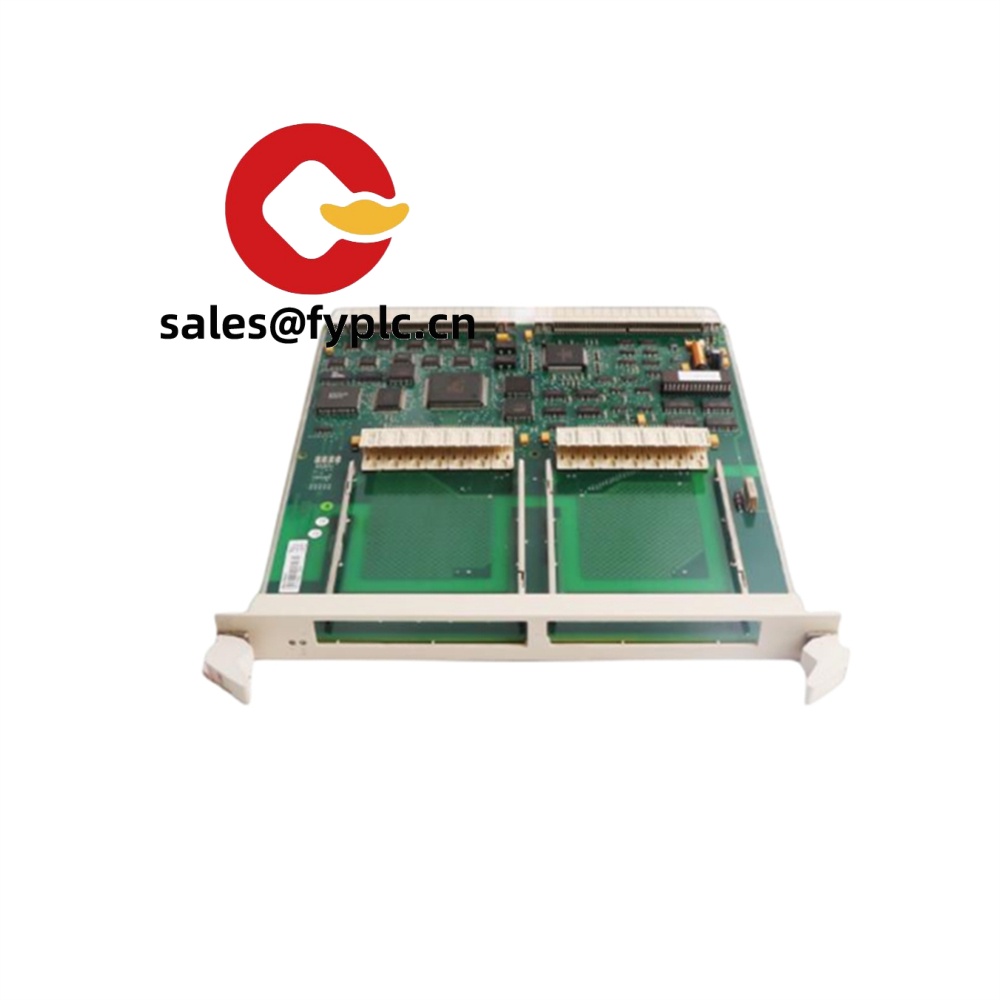

- Force-guided relay outputs: Two independently monitored, positively driven contacts (1NC + 1NO per channel) with mechanical linkage—certified to EN 60947-5-1 and verified during factory test.

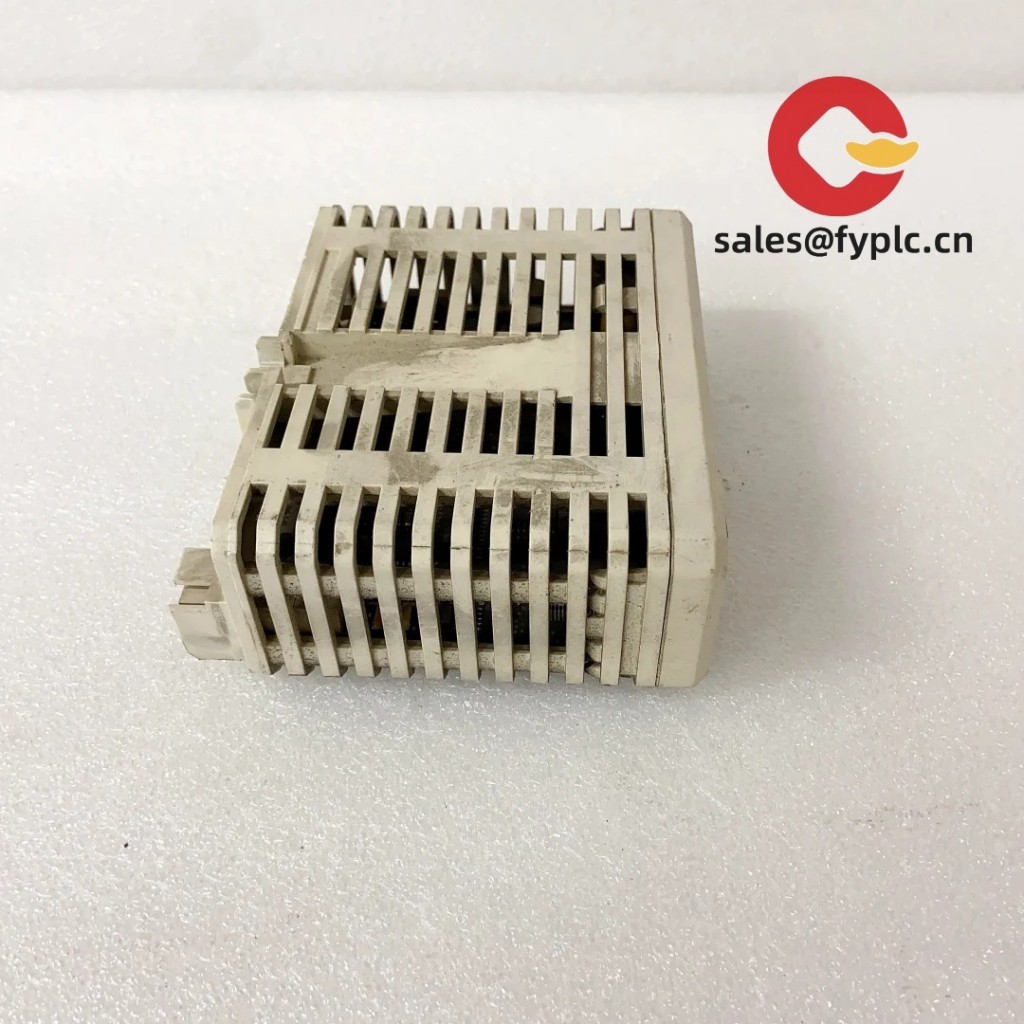

- DIN rail mount, space-saving footprint: Only 22.5 mm wide (half the width of legacy ABB S200 series). Fits alongside standard signal conditioners or I/O modules without crowding terminal strips.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB SB512 |

| HS Code | 8536.49.00 (Electromechanical relays for a voltage ≤ 1 kV) |

| Power Requirements | 24 VDC ±20%, 25 mA typical (no auxiliary supply needed) |

| Dimensions (W × H × D) | 22.5 × 90 × 112 mm (DIN rail mounted) |

| Weight | Approx. 120 g |

| Operating Temperature | −20 °C to +55 °C (derating applies above 40 °C) |

| Signal Input Type | 2 × safety-rated inputs (ch. A & B), 24 VDC, category 4 / SIL 3 / PL e compliant |

| Output Type | 2 × force-guided relay outputs (each: 1NO + 1NC), 250 VAC / 30 VDC, 6 A resistive |

| Communication Interfaces | None (standalone device); status signals only via LEDs and hardwired outputs |

| Installation Method | Top-hat DIN rail (TS35-15 or TS35-7.5), screw terminal wiring (0.14–1.5 mm²) |

Application Fields

This relay shows up frequently on semi-automated assembly stations, robotic workcells with removable access panels, and small-to-midsize packaging machinery—especially where OEMs need fast CE marking turnaround. One customer in Germany recently used six SB512 units across a modular carton-packing line: two for E-stop circuits, three for hinged safety doors with key-operated locks, and one for muting a light curtain during pallet transfer. It appears that its plug-and-play nature reduces validation effort significantly versus custom-configured safety controllers.

Advantages & Value

- No software licensing or configuration tools: Saves engineering hours and avoids version-compatibility headaches—ideal when your controls team doesn’t have dedicated safety-certified staff.

- Built-in cross-monitoring: Detects welded contacts or short circuits between channels—a subtle but critical feature missing in many budget relays. In practice, this has prevented at least two near-miss incidents on client sites where older relays failed silently.

- Global spare parts availability: Unlike niche safety brands, ABB maintains regional stock of SB512 across EU, NA, and APAC—so replacement isn’t held up by 12-week lead times.

- Cost-efficient scaling: At ~$195/unit (in volume), it sits between basic relays (~$90) and entry-level safety PLCs (~$650+), offering the best balance for applications needing dual-channel redundancy but not complex logic.

Installation & Maintenance

Mount it vertically on a clean, unpainted TS35 DIN rail inside an IP54-rated cabinet—avoid locations near heat sources (>40 °C ambient) or high-vibration zones (e.g., directly beside servo drives). Use ferrules on all wires and torque terminals to 0.5 N·m. For safety integrity, verify output contact resistance annually (should be <100 mΩ), and inspect LEDs quarterly for consistent brightness—dimming can indicate aging internal components. Firmware updates aren’t applicable (it’s hardware-logic based), but ABB does issue occasional revision kits for contact wear compensation; these are free and field-installable in under 5 minutes.

Quality & Certifications

Certified to EN ISO 13849-1 (PL e, Category 4), EN 62061 (SIL 3), UL 508, and RoHS 3 compliant. Carries full CE marking with EU Declaration of Conformity available upon request. All units undergo 100% functional testing before shipment—including forced-contact stress verification and dielectric strength testing at 2.5 kV AC. Warranty is 365 days from date of delivery, covering material and workmanship defects. If a unit fails under normal use, we replace it—not repair it—within 3 business days of receiving the RMA.

Our Order Placement Process & Guarantees:

• Delivery: 1 week for in-stock units (SB512 is typically held in EU and US distribution centers)

• Max lead time: 4 weeks—never longer, even during peak season

• Payment: 50% advance, balance before dispatch

• Shipping: Fedex, UPS, or DHL Express (tracking provided); customs documentation included

• Warranty: Full 365-day coverage—no exclusions for industrial use

Reviews

There are no reviews yet.