Description

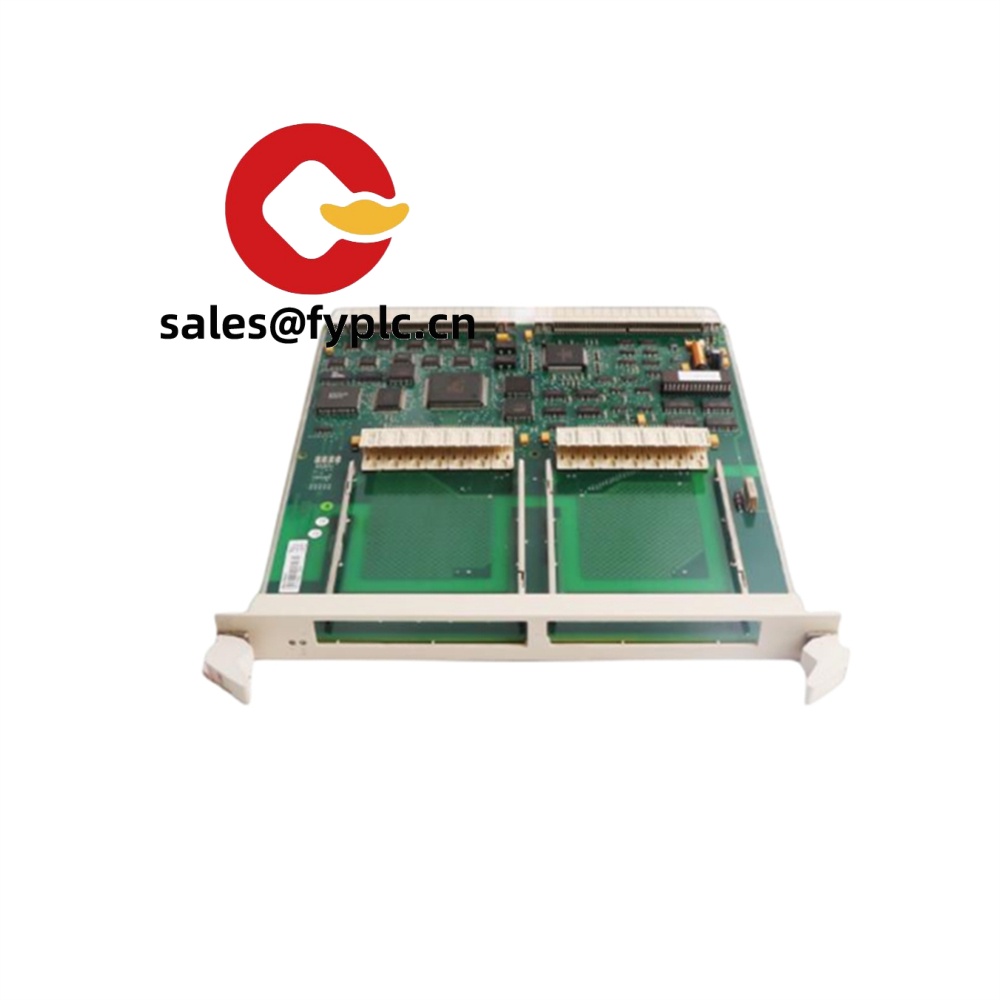

ABB SC513 – High-Performance Servo Controller for Precision Motion Control

If you’re working on automated assembly lines or CNC machinery, the ABB SC513 is one controller that tends to stand out—not because it shouts, but because it delivers. From my experience supporting integration teams in packaging and metal forming, this module strikes a balance between responsiveness and durability, especially in environments where cycle times matter and downtime isn’t an option.

Key Features

- Precision servo control: Manages up to 4 axes with high-speed position feedback loops—typically used in pick-and-place units or robotic arms needing tight path accuracy.

- Integrated diagnostics: Real-time fault logging helps reduce troubleshooting time. One customer mentioned it cut their mean repair time by nearly 30% after switching from a legacy Allen-Bradley setup.

- Modular design: Designed to snap into ABB’s Symphony Plus rack system, which makes field replacement straightforward without rewiring everything.

- Firmware flexibility: Supports online tuning and parameter backup, so upgrades don’t require full recalibration—a small thing, but it seems to save hours during maintenance windows.

- EMC resilience: Shielded circuitry helps maintain signal integrity even in electrically noisy areas like stamping plants or welding cells.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / SC513 |

| HS Code | 85371090 |

| Power Requirements | 24 VDC ±10%, max draw 2.1 A |

| Dimensions & Weight | 120 mm × 180 mm × 55 mm / 0.8 kg |

| Operating Temperature | 0°C to +55°C (with derating above 45°C) |

| Signal I/O Types | Digital inputs (24V), analog outputs (±10V), encoder feedback (TTL/RS422) |

| Communication Interfaces | Profibus DP, optional Modbus RTU via expansion card |

| Installation Method | DIN-rail mounted, compatible with IP20 control cabinets |

Application Fields

The SC513 shows up most often in mid-tier automation setups—think cartoning machines, rotary indexing tables, or laser cutting systems where motion coordination matters more than sheer speed. It’s not built for gigahertz-level updates, but in many cases, it’s more than enough. We’ve seen it deployed successfully in food processing lines where washdown conditions rule out less-sealed alternatives, thanks to its conformal coating and stable firmware under humidity swings.

Advantages & Value

Procurement teams tend to appreciate the long-term availability of ABB’s SC series—unlike some vendors that discontinue models every few years, these controllers often remain supported for over a decade. Compatibility with existing Symphony I/O modules also reduces migration costs. While not the cheapest on day one, the total cost of ownership typically improves due to fewer field failures and accessible spare part networks across Europe and North America.

Installation & Maintenance

Mount it in a standard industrial control cabinet—minimum clearance of 50 mm on each side for airflow. Avoid placing near VFDs or transformers generating strong EMI unless shielded conduit is used. Wiring should follow star grounding practices to prevent ground loops, especially when linking multiple servos. For maintenance, check terminal torque every 18 months, clean dust buildup semi-annually, and consider quarterly firmware audits to catch version drift across machines.

Quality & Certifications

Certified to CE, UL 508I, and RoHS standards. Built under ISO 9001-controlled processes at ABB facilities in Germany and China. The unit comes with a 365-day warranty, covering defects in materials and workmanship. No registration required—just proof of purchase.

Delivery: 1 week for in-stock units, never exceeding one month.

Payment: 50% upfront, balance before shipment.

Shipped via FedEx, UPS, or DHL—your choice.

Reviews

There are no reviews yet.