Description

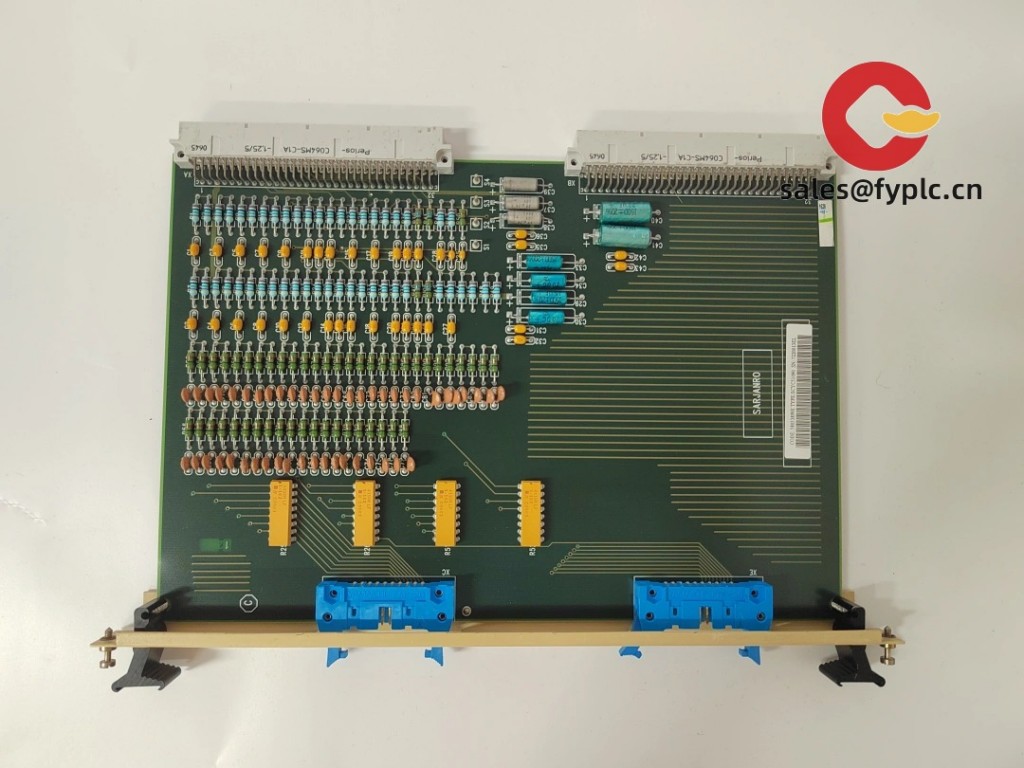

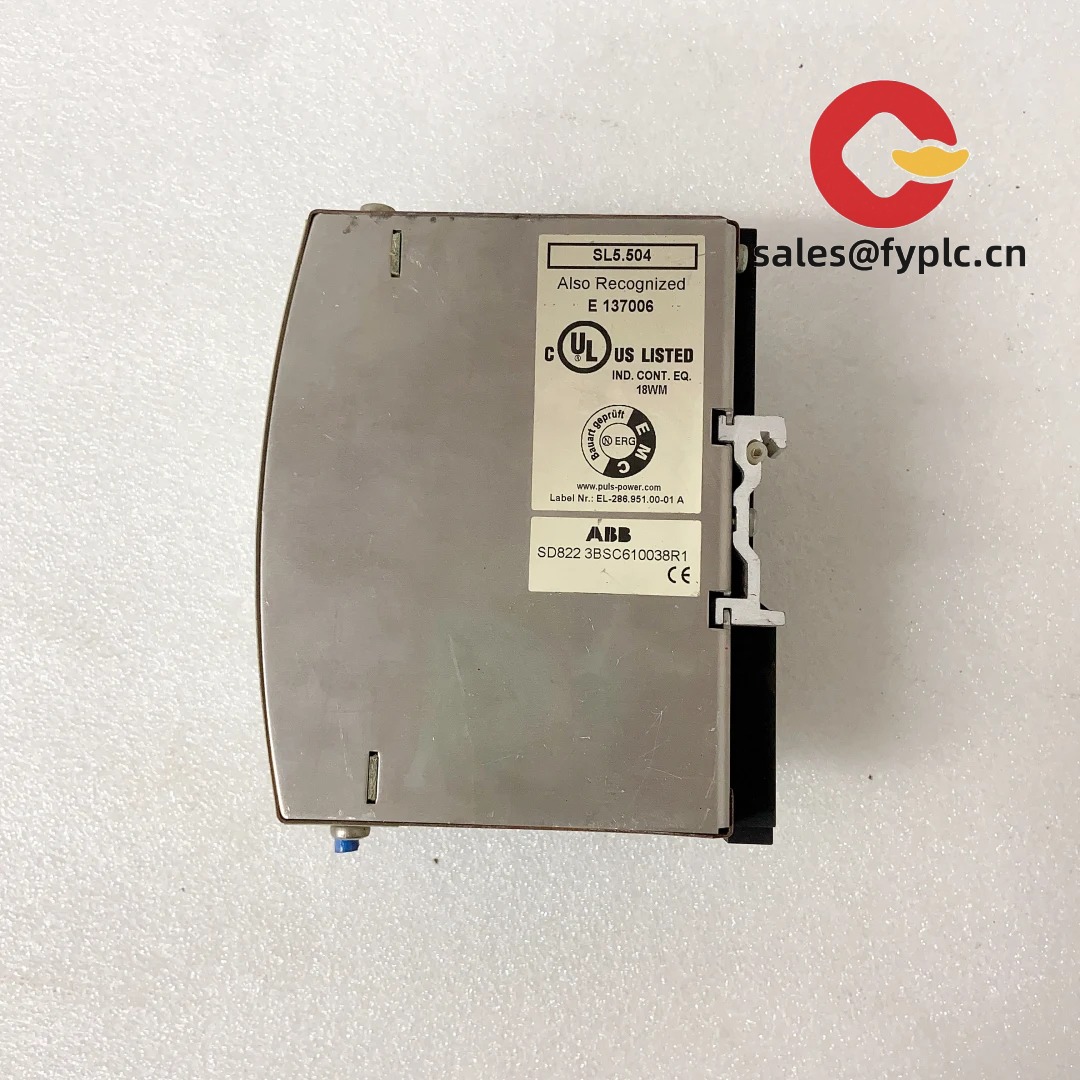

ABB SD822 (3BSC610038R1) – Reliable S800/Advant Digital I/O Module for Discrete Control

The ABB SD822 (3BSC610038R1) is part of the ABB S800/Advant I/O family, designed for dependable discrete signal handling on machine lines, process skids, and plant utilities. From my experience, it’s a straightforward fit when you need robust digital I/O in an ABB 800xA, Advant Master, or AC 800M environment. One thing I appreciate is how it slots into standard TU8xx terminal bases, so swapping or expanding channels typically takes minutes and doesn’t require rewiring the entire cabinet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- S800/Advant compatible – Works within ABB 800xA/Advant architectures using TU8xx terminal bases and standard ModuleBus power.

- Hot-swappable module – Swap the module with the system powered; in most cases, it minimizes downtime during maintenance.

- Channel status LEDs – Quick visual diagnostics; you’ll notice issues faster during commissioning and routine checks.

- Galvanic isolation – Improves noise immunity and protects the controller side from field disturbances.

- Diagnostics and fault reporting – Typical S800 diagnostics help you pinpoint wiring faults or channel issues with less guesswork.

- DIN-rail installation with TU8xx – Clean, compact installation that scales easily as I/O counts grow.

Technical Specifications

| Brand / Model | ABB SD822 (3BSC610038R1) |

| HS Code | 8538.90 (Parts suitable for use with switching/protective apparatus) |

| Power Requirements | Powered via S800 ModuleBus from TU8xx base; nominal 24 VDC system supply, typical module consumption < 3 W |

| Dimensions & Weight | Single-width S800 form factor; typically ~122 × 45 × 102 mm; approx. 0.2 kg |

| Operating Temperature | 0 to +55 °C (industrial cabinets); storage typically -40 to +70 °C |

| Signal I/O Types | Digital I/O within the S800/Advant family; commonly used for 24 VDC discrete signals (channel count and thresholds per SD822 variant) |

| Communication Interfaces | S800 ModuleBus via TU8xx base; no external fieldbus port on the front of the module |

| Installation Method | Plug-in module for TU8xx terminal units; DIN-rail mounted assemblies; IP20 cabinet use |

Application Fields

You’ll typically see the SD822 in discrete control applications where uptime and easy maintenance matter:

- Packaging and assembly lines – monitoring sensors, limit switches, and interlocks

- Oil & gas skids – valve packs, compressor skids, and burner management auxiliaries

- Water & wastewater – pump stations, blower control, and MCC interfacing

- Power and utilities – auxiliary systems, dampers, and balance-of-plant I/O

- Metals and mining – conveyor logic, chute gates, and safety circuits (non-SIL)

- Building and data centers – plant utilities and discrete alarms into 800xA

A maintenance lead told me they replaced an SD-series module during a shift change and were back online in under five minutes—no rewiring, just a clean plug-in on the existing TU base. That’s the kind of field practicality that tends to stick.

Advantages & Value

- Reliability – Proven S800 platform stability; reduced nuisance trips thanks to isolation and noise immunity.

- Compatibility – Matches ABB 800xA/Advant ecosystems, leveraging existing TU8xx bases and ModuleBus power.

- Lower lifecycle cost – Hot-swap capability and standard wiring reduce service time and spares logistics.

- Scalable – Add channels by extending TU bases; the footprint stays compact.

- Supportable – Documentation and diagnostics are mature, which, in many cases, shortens troubleshooting.

Installation & Maintenance

- Cabinet and mounting – Install on DIN rail with TU8xx terminal units (e.g., TU810 series). Allow ventilation space; typical enclosure IP54+ for industrial areas.

- Power & grounding – Provide clean 24 VDC system power; bond cabinet ground; keep I/O commons and shields consistent with ABB wiring rules.

- Wiring – Use appropriate conductor sizes (commonly 0.5–2.5 mm²). Route high-voltage and high-noise cables separately from I/O lines.

- Safety – De-energize field circuits when working on terminals. Observe ESD precautions when handling the module.

- Commissioning – Verify channel status via LEDs and the control system diagnostics. Confirm channel mapping in 800xA/Advant configuration.

- Routine maintenance – Periodically check terminal tightness, clean dust with dry air, and review diagnostics. Firmware updates generally apply to controllers; I/O modules typically require no firmware handling.

Quality & Certifications

- CE compliant for industrial environments

- UL/cUL listed (industrial control equipment, where applicable)

- RoHS compliant materials

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty practice typically applies alongside a 365-day seller warranty

Note: Channel count and thresholds can vary across SD822 variants. If you need exact per-channel specs or the recommended TU base for your panel, share your current controller and I/O list and I’ll match it precisely.

Reviews

There are no reviews yet.