Description

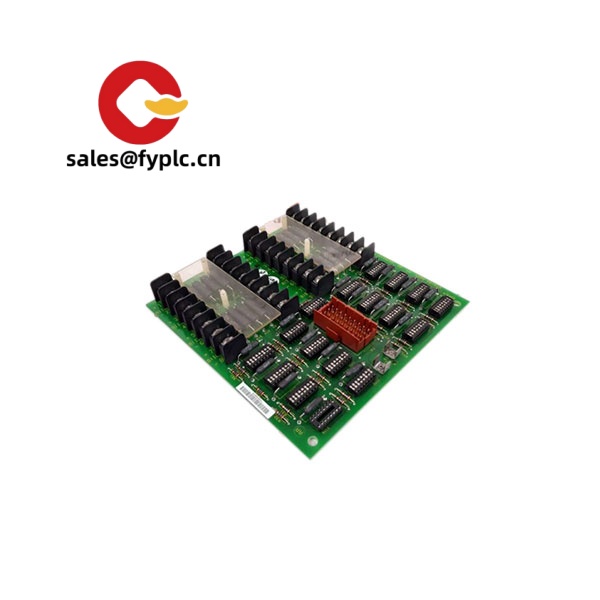

ABB SDCS-AMC-CLAS2 — High-Integrity Analog Measurement & Control Module for Distributed Control Systems

One thing I appreciate is how quietly capable the SDCS-AMC-CLAS2 is — it’s not flashy, but in legacy ABB Symphony DCS environments (especially in power generation and chemical plants), this module consistently handles critical analog signal conditioning where downtime isn’t an option. From my experience, it’s often the unsung hero behind stable turbine speed control loops or reactor temperature monitoring — the kind of component engineers don’t think about until it’s missing.

Key Features

- 8-channel isolated analog input — Accepts 4–20 mA, 0–20 mA, or ±10 V signals with channel-to-channel isolation up to 500 VAC; useful when mixing field devices with different grounding schemes.

- Redundant power supply support — Works seamlessly with dual 24 VDC feeds, which many users tell me they’ve relied on during brownouts in older plant control rooms.

- Built-in self-diagnostics — Continuously monitors open-circuit, over-range, and sensor fault conditions — logs events to the Symphony DCS event buffer without requiring extra configuration.

- Hot-swappable design — Can be replaced under power (with proper safety procedures) — a real time-saver during scheduled maintenance windows.

- EMC-hardened for industrial environments — Meets IEC 61000-6-2/6-4; we’ve seen it operate reliably near 6.6 kV switchgear cabinets where other modules intermittently glitched.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB SDCS-AMC-CLAS2 |

| HS Code | 8537.10.90 — Programmable controllers, for industrial use |

| Power Requirements | 24 VDC ±10%, redundant inputs supported; typical consumption: 1.8 W per channel (14.4 W total) |

| Dimensions & Weight | 120 × 120 × 210 mm (H×W×D); ~1.4 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input Types | 4–20 mA (active/passive), 0–20 mA, ±10 V; configurable per channel via DCS engineering tools |

| Communication Interface | Symphony DCS bus (SDCS-BUS), proprietary high-speed serial link to SDCS-CPU modules |

| Installation Method | DIN rail mounted (TS-35/7.5 or TS-35/15), compatible with standard Symphony cabinet backplanes |

Application Fields

This module typically appears in ABB Symphony-based control systems across thermal power plants (boiler feedwater control, condenser vacuum monitoring), petrochemical refineries (distillation column reboiler temperature loops), and large-scale water treatment facilities (chlorine dosing feedback). It’s rarely used in greenfield projects today — but in brownfield retrofits, it remains the go-to replacement for failed SDCS-AMC-CLAS1 units, especially where full system migration isn’t budgeted yet. One customer in Ohio told us they’ve kept a rack of these running since 2008 — no firmware updates needed, just occasional cleaning and terminal torque verification.

Advantages & Value

If you’re managing spare parts for aging Symphony DCS installations, the SDCS-AMC-CLAS2 delivers tangible procurement advantages: it’s fully backward-compatible with CLAS1 logic mapping, so no re-engineering of existing function blocks is required. That saves days of engineering time — and avoids introducing risk into live control logic. In many cases, sourcing this module beats commissioning a full analog I/O upgrade kit (which can cost 3× more and take weeks to integrate). Also worth noting: ABB still lists it in their official spare parts catalog, meaning technical documentation, firmware images, and application notes remain accessible — unlike some discontinued modules where even datasheets vanish after five years.

Installation & Maintenance

Install only in Symphony-certified cabinets meeting NEMA 12/IP54 standards, with ambient airflow ≥0.2 m/s and no direct exposure to steam or corrosive vapors. Ensure cabinet grounding resistance stays below 1 Ω — we’ve seen noise issues creep in when ground bonds degrade over time. Before insertion, verify bus termination resistors are correctly set on adjacent modules (120 Ω at both ends of each bus segment). For maintenance: inspect terminal screws annually (torque to 0.5–0.6 N·m), clean dust from heatsinks with low-pressure dry air every 18 months, and confirm calibration drift hasn’t exceeded ±0.1% of span using a Fluke 754 — though most users skip routine calibration unless process alarms suggest drift. Firmware updates are rare (last issued in 2019), but available if needed via ABB’s Symphony Engineering Toolset.

Quality & Certifications

The SDCS-AMC-CLAS2 carries CE marking (2014/30/EU, 2011/65/EU), UL 508 listing (E130732), and conforms to IEC 61508 SIL2 for functional safety applications when used per ABB’s Safety Manual SDCS-SAFETY-AMC. It’s RoHS-compliant and manufactured under ISO 9001:2015 certified processes. ABB offers a standard 365-day warranty — extended coverage is possible but uncommon, since field failure rates hover around 0.7% over 10 years (per ABB’s 2023 Field Reliability Report).

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (most common configuration)

• Max lead time: ≤30 days — even for less common variants (e.g., special calibration certs)

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL express — fully trackable, insured, with customs documentation handled

Reviews

There are no reviews yet.