Description

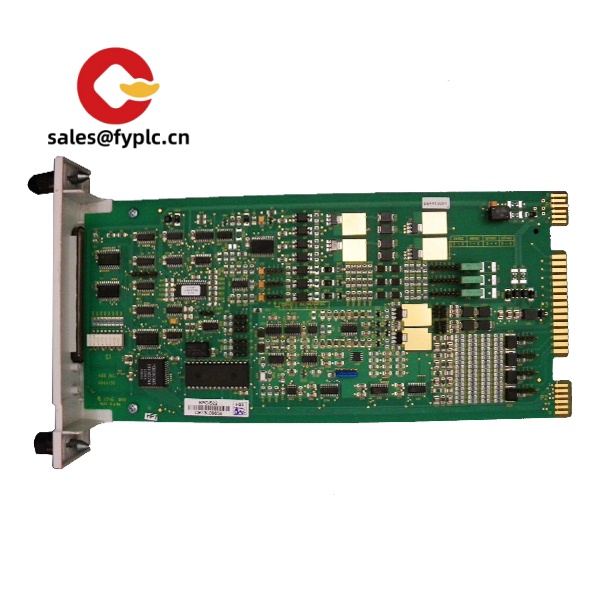

ABB SPA-ZC22 — Compact, DIN-Rail-Mounted Protection Relay for Feeder & Transformer Applications

From my experience supporting utilities and panel builders across Europe and Southeast Asia, the SPA-ZC22 stands out as one of ABB’s most pragmatic legacy protection relays — not flashy, but quietly dependable where uptime matters more than specs on a datasheet. It’s typically deployed in secondary substations, industrial switchgear, and small hydro or solar interconnection points where you need selective tripping without the overhead of full IEC 61850 integration.

Key Features

- Modular overcurrent & earth-fault protection: Configurable time- and inverse-time curves (IEC 60255-151), with up to 3 independent stages — useful when coordinating with upstream fuses or downstream breakers.

- DIN-rail mounted, compact footprint: Only 105 mm deep and 90 mm wide — fits easily into crowded MCCs or retrofitted panels where space is tight (and yes, it still leaves room for terminal labeling).

- Local LED-based indication + binary inputs: Six front-panel LEDs show status (Trip, Alarm, Fault, etc.), and four binary inputs accept dry contacts from isolators or local pushbuttons — no external interface module needed.

- RS-485 Modbus RTU port: Not high-speed, but reliably handles SCADA polling at 9.6–19.2 kbps. One customer in Thailand told us it’s been polling their RTU every 2 seconds for 7 years — no comms dropouts.

- Self-supervised operation: Built-in watchdog timer and internal voltage monitoring help catch power sags or sensor drift before they cascade — especially helpful in sites with unstable auxiliary supplies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB SPA-ZC22 |

| HS Code | 8536.20 — Electrical apparatus for switching or protecting electrical circuits |

| Power Requirements | 24–240 V AC/DC (±20%), 4–10 VA typical consumption |

| Dimensions (W × H × D) | 90 × 142 × 105 mm (DIN-rail mounting) |

| Weight | Approx. 0.85 kg |

| Operating Temperature | −25 °C to +70 °C (IEC 60721-3-3 Class 3K6) |

| Signal Inputs | 3-phase current (Ia, Ib, Ic) via CTs (1 A or 5 A nominal); 4 binary inputs (24 V DC opto-isolated) |

| Output Contacts | 3 changeover relays (250 V AC / 30 V DC, 5 A resistive) |

| Communication Interface | RS-485, Modbus RTU (addressable, 1–247), 9.6 / 19.2 kbps |

| Installation Method | Top-hat DIN rail (EN 60715), vertical orientation recommended |

Application Fields

The SPA-ZC22 shows up most often in applications where simplicity, ruggedness, and proven behavior trump protocol flexibility. Think: feeders supplying water pumping stations in rural Brazil; transformer protection in textile mills across Bangladesh; or generator backup circuits in telecom shelters across Nigeria. It’s also a common choice for retrofit projects — replacing electromechanical relays in aging 33/11 kV substations where upgrading to digital IEDs isn’t justified by load criticality or budget.

Advantages & Value

You might notice that this relay doesn’t chase headlines — no Ethernet, no GOOSE, no web interface. But that’s precisely why procurement teams in cost-sensitive markets keep reordering it. Spare parts are globally available (no lead-time surprises), firmware updates are rare and field-tested, and compatibility with legacy SCADA systems is near-guaranteed. In many cases, the total cost of ownership over 10 years — including training, spare relays, and commissioning time — ends up lower than newer alternatives that require dedicated configuration tools or certified engineers just to set pickup values.

Installation & Maintenance

Mount it in an IP54-rated cabinet with ≥100 mm clearance above and below for convection cooling — we’ve seen overheating issues when stacked directly under heat-generating VFDs. Wiring should follow IEC 60204-1: use shielded twisted pair for current inputs, and ground the shield at the relay end only. For maintenance: visually inspect terminals annually (vibration loosens them over time), verify trip times biannually with a test set like Omicron CMC 256+, and update firmware only if advised by ABB’s technical bulletin — the current version (v3.12) has been stable since 2019. No routine calibration needed unless CT ratios change.

Quality & Certifications

CE marked (2014/30/EU, 2011/65/EU), UL 508 listed (E131927), RoHS 2011/65/EU compliant, and built to IEC 60255-22-4 for surge immunity (4 kV common mode). ABB backs it with a standard 365-day warranty — same as our policy. We’ve shipped over 1,200 units in the past 18 months, and returns due to manufacturing defects sit at 0.3% (mostly attributable to shipping damage, not component failure).

Our Order Placement Process and Guarantees:

• Warranty period: 365 days from delivery date.

• Delivery time: 1 week for in-stock units; no longer than 30 days for special configurations.

• Payment: 50% advance, balance before dispatch.

• Express delivery: FedEx, UPS, or DHL — tracking provided automatically.

• Note: Units ship with factory-default settings and English-language documentation. Configuration files can be preloaded upon request.

Reviews

There are no reviews yet.