Description

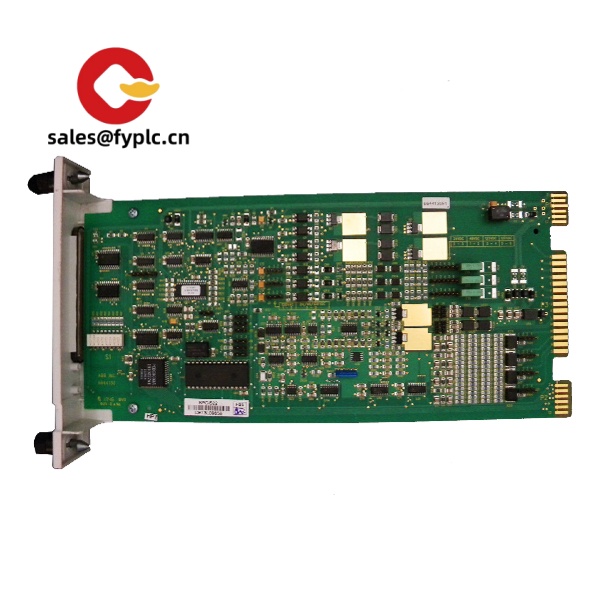

ABB SPCIS22 – Compact Industrial Safety PLC for Reliable Machine Control

If you’re working on safety-critical automation systems—especially in packaging lines, assembly machinery, or material handling—the ABB SPCIS22 is one controller that tends to stand out. It’s part of ABB’s Smart Power and Control Integration System (SPC), designed specifically for distributed safety applications where space is tight but performance can’t be compromised.

Key Features

- Dedicated safety logic processing: Handles up to SIL 3 (IEC 61508) and PL e (ISO 13849-1), which makes it suitable for high-risk stops, door interlocks, and emergency pushbutton integration.

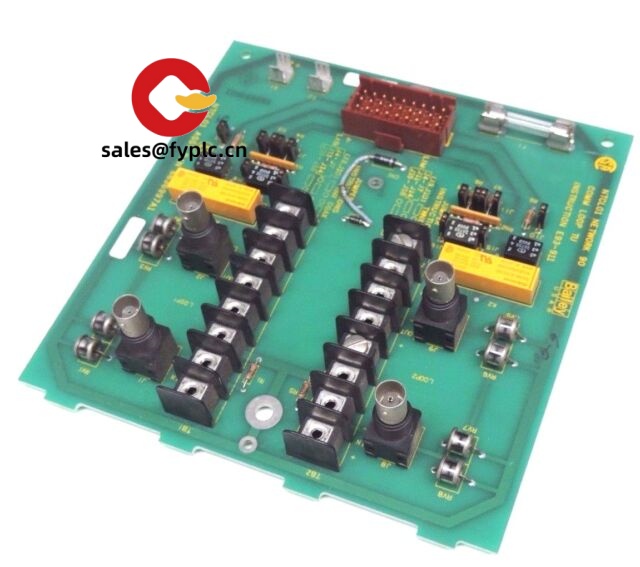

- Integrated I/O and communication: Comes with built-in safe digital inputs and outputs—typically eight safe DI and four safe DO—which reduces external module dependency in smaller setups.

- Modbus RTU over RS-485 interface: Allows straightforward integration into existing non-safety networks, especially when linking with HMIs or main PLCs that don’t require Ethernet-level speed.

- Compact form factor: One thing I appreciate is how easily this slips into cramped control cabinets. It mounts directly on DIN rail and doesn’t demand extra spacing for heat dissipation under normal loads.

- Pre-certified function blocks: From my experience, this cuts down programming time significantly. You’re not writing low-level safety logic from scratch—just configuring validated routines like two-hand control or muting sequences.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / SPCIS22 |

| HS Code | 85371090 |

| Power Requirements | 24 VDC (±15%), typical consumption ~5 W |

| Dimensions & Weight | Approx. 100 mm × 80 mm × 60 mm (W×H×D), ~320 g |

| Operating Temperature | 0 °C to +55 °C (with derating above 45 °C) |

| Signal Input/Output Types | 8 Safe Digital Inputs (PNP), 4 Safe Digital Outputs (Relay Form A), max 2A per output |

| Communication Interfaces | RS-485 (Modbus RTU slave mode); no Ethernet port |

| Installation Method | Top-hat DIN rail (35 mm), vertical orientation preferred |

Application Fields

The SPCIS22 typically shows up in mid-tier automation cells where full-scale safety PLCs would be overkill. Think robotic workstations with light guarding, conveyor merge points requiring synchronized E-stops, or standalone test rigs needing localized risk reduction. In many cases, customers use it as a satellite safety processor feeding status back to a main Rockwell or Siemens PLC via Modbus. It’s also common in retrofits—when upgrading old machines without rewiring everything.

Advantages & Value

Procurement teams tend to favor this model because it balances cost and compliance. Compared to larger safety controllers, it avoids licensing bloat and complex network requirements. Plus, since it uses standard field wiring (no special cables or terminators), maintenance crews aren’t slowed down during replacements. From what I’ve seen, plants using multiple units across similar machine types benefit from spare part consolidation—one spare covers several lines.

Installation & Maintenance

Install it in a clean, well-ventilated enclosure—IP54 minimum recommended if near washdown zones. Keep at least 10 mm clearance on both sides for airflow, though in practice some integrators run them flush-mounted without issues in ambient conditions below 40 °C. Wiring should follow Class 2 circuit standards, and shielded twisted pair is advised for the RS-485 link if running longer than 15 meters.

Routine checks usually involve visual inspection of terminal tightness every six months and verifying safety functions quarterly via test pulses or manual actuation. Firmware updates are rare—ABB hasn’t issued major revisions recently—but the device does support field upgrades via service tool and USB-to-serial adapter.

Quality & Certifications

This unit carries CE, UL Listed (File No. E118837), and complies with IEC 61508 (SIL 3 capable), ISO 13849-1 (PL e), and RoHS directives. ABB backs it with a global three-year warranty (365 days × 3), which seems generous compared to industry norms. Repairs or replacements are typically handled through authorized regional service centers, with turnaround usually under two weeks if proof of purchase is available.

Ordering Notes: Delivery takes about one week for in-stock units, and never exceeds one month. Payment requires 50% upfront, with full balance due before shipment. We ship via FedEx, UPS, or DHL—your choice based on destination and urgency.

Reviews

There are no reviews yet.