Description

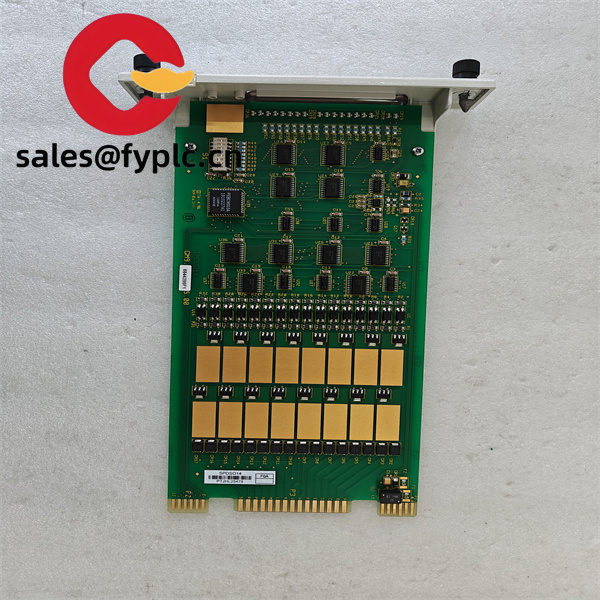

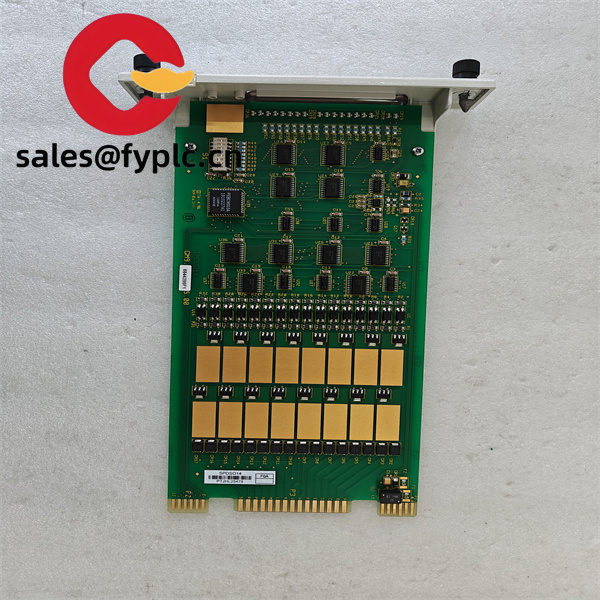

ABB SPDSO14 switch output submodule

SPDSO14

| Label |

Specification |

| Model Number |

SPDSO14 |

| Brand |

ABB |

| Type |

Digital Output Slave Module |

| Dimensions |

3.7 cm x 31.3 cm x 17.7 cm |

| Weight |

0.2 kg |

| Power Supply |

DC 24V |

| Number of Outputs |

16 |

| Connection Type |

Terminal Block |

| Operating Temperature |

– 25 °C to + 60 °C |

| Storage Temperature |

– 40 °C to + 85 °C |

| Output Current per Channel |

250 mA at 24 VDC, 125 mA at 48 VDC |

| Isolation |

Each channel is optically isolated |

| Application Compatibility |

Works with Symphony Plus controller; suitable for a wide range of industrial applications like manufacturing, process control |

| Mounting Options |

Can be mounted on a DIN rail |

The ABB SPDSO14 module comes with a host of features that make it stand out in industrial environments. Its 16 – channel configuration offers substantial flexibility for controlling a variety of field devices. Whether it’s actuators, solenoids, relays, or other equipment crucial for industrial processes, the SPDSO14 can manage them effectively. Each channel is optically isolated, which is a significant advantage in industrial settings where electrical interference is common. This isolation helps prevent electrical noise from affecting the output signals, ensuring stable and reliable operation of the connected devices.

SPDSO14

The module is designed to handle different voltage levels with specific current ratings. It can switch 24 VDC at 250 mA and 48 VDC at 125 mA per channel. This versatility allows it to be used in diverse applications with varying power requirements. The ability to cable – connect to solid – state relays on the NT DO 02 termination unit or, optionally, to a relay assembly for driving electromechanical relays further expands its application scope.

The ABB SPDSO14 is well – equipped to operate in harsh industrial conditions. With an operating temperature range from – 25 °C to + 60 °C, it can function reliably in environments where extreme temperatures are the norm. This is crucial for industries such as steel manufacturing, where high – temperature environments are common, or in cold storage facilities in the food and beverage industry. Additionally, its storage temperature range of – 40 °C to + 85 °C ensures that the module can be stored safely in different conditions before installation.

In terms of physical design, the SPDSO14 has a compact structure. Measuring 3.7 cm x 31.3 cm x 17.7 cm and weighing only 0.2 kg, it can be easily integrated into existing control systems without taking up excessive space. The terminal – block connection type simplifies the wiring process, making installation and maintenance more straightforward. Technicians can quickly connect and disconnect wires as needed, reducing the time spent on system setup and troubleshooting.

The ABB SPDSO14 finds extensive use in multiple industrial sectors. In manufacturing plants, it plays a vital role in controlling conveyor belts, robotic arms, and other automated machinery. For example, in an automotive assembly line, the SPDSO14 can be used to control the solenoids that operate pneumatic valves, which in turn control the movement of robotic arms used for tasks like welding, painting, and part assembly. By providing precise digital output control, it ensures the smooth and coordinated operation of these complex manufacturing processes, improving production efficiency and product quality.

SPDSO14

In process control industries such as chemical plants and oil refineries, the SPDSO14 is used to manage various valves and pumps. In a chemical reaction process, it can control the opening and closing of valves to regulate the flow of different chemical substances, ensuring that the reaction proceeds as expected. In an oil refinery, it can be used to control the pumps that transfer crude oil or refined products, maintaining the integrity of the refining process and ensuring safe and efficient operations.

SPDSO11 – A related module that may have a different number of output channels or slightly different electrical specifications. It could be a more basic option for applications with lower output requirements or simpler control needs.

SPDSI14 – This is a digital input module from ABB. In an industrial system, the SPDSO14 can work in tandem with the SPDSI14. The SPDSI14 can be used to receive digital input signals from sensors, switches, or other devices, and the SPDSO14 can then use this information to generate appropriate output signals to control actuators or other equipment.

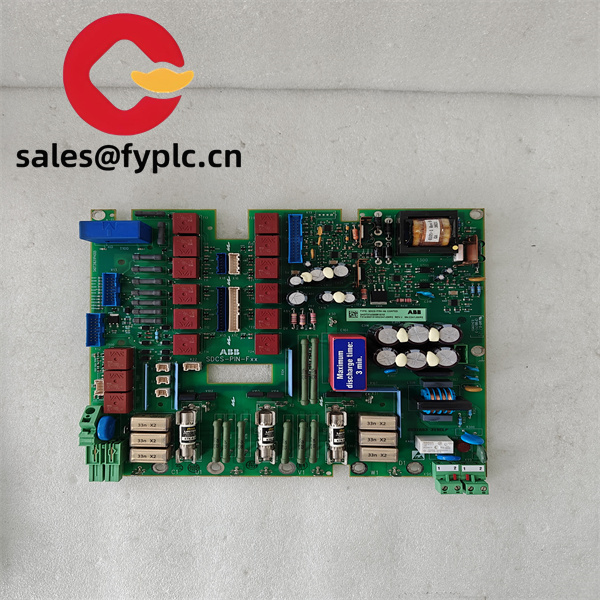

CI840 – A field – bus communication interface module. In a larger industrial control system, the SPDSO14 can communicate with other components, including controllers, through the CI840. The CI840 enables communication over the PROFIBUS – DPV1 field – bus, which can be used to send control commands to the SPDSO14 and receive status information from it.

NT DO 02 – The termination unit that the SPDSO14 can cable – connect to. The combination of the SPDSO14 and NT DO 02 provides a complete solution for driving solid – state relays in industrial applications.

TU846 and TU847 – These are terminal units related to the CI840. Although not directly integrated with the SPDSO14 in the same way as the NT DO 02, in a comprehensive industrial control setup, all these components can be part of a larger system where the SPDSO14 interacts with other elements through various communication and connection methods.

Installing the ABB SPDSO14 requires following a few key steps. First, when mounting it on a DIN rail, ensure that the rail is securely installed and free from any damage. The SPDSO14 should be firmly attached to the rail to prevent vibrations from affecting its performance. When making electrical connections to the terminal blocks, use appropriate wire gauges according to the current ratings of the module. Tighten the screws on the terminal blocks properly to ensure good electrical contact and prevent loose connections that could lead to intermittent operation or overheating.

SPDSO14

For long – term maintenance, regular inspections of the SPDSO14 are essential. Visually check the module for any signs of physical damage, such as cracks in the casing or burnt – out components. Monitor the output signals regularly to ensure that they are operating as expected. If there are any issues with the output, check the wiring connections first and then refer to the module’s troubleshooting guide provided by ABB. Periodically clean the module to remove dust and debris, especially in environments where these can accumulate easily, as this can affect the module’s heat dissipation and electrical performance over time.

ABB offers a reliable warranty and comprehensive support for the SPDSO14 module. The company’s extensive documentation, including user manuals, technical reference guides, and application notes, can assist users in understanding the module’s functionality, installation, and maintenance. In case of any technical problems, ABB’s technical support team is available to provide remote assistance or, if necessary, on – site support. This level of support gives industrial users confidence in the SPDSO14 module, knowing that they have access to the resources needed to keep their industrial control systems running smoothly.

For more information, please click below to learn more:

Reviews

There are no reviews yet.