Description

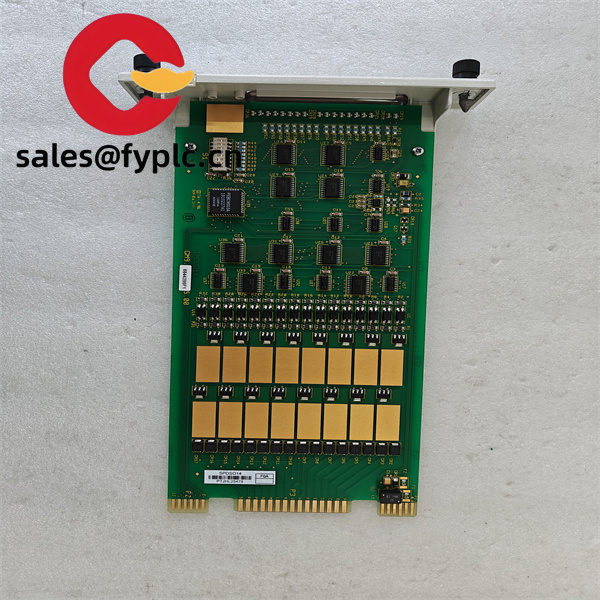

ABB SW-190148 Deionization Tank Unit Module

SW – 190148

The ABB SW – 190148 showcases remarkable functional strengths and design advantages that set it apart in real – world industrial environments. This module has been engineered to deliver lightning – fast data processing speeds, ensuring that information is relayed between different components of an industrial system in the blink of an eye. In a manufacturing setup where split – second decisions can impact production output, the SW – 190148 enables seamless communication, reducing delays and improving overall efficiency.

| Label |

Specification |

| Model Number |

SW – 190148 |

| Brand |

ABB |

| Type |

Industrial Control and Data Interaction Module |

| Input Voltage |

24V DC |

| Operating Temp |

-25°C to 65°C |

| Communication Method |

Ethernet, Profibus DP, Modbus RTU |

| Mounting |

DIN Rail |

| Weight |

1.2 kg |

| Certifications |

CE, UL, ISO 9001 |

| Dimensions |

180mm x 120mm x 60mm |

| IP Rating |

IP20 |

| Protocols Supported |

TCP/IP, UDP, S7 Communication |

Its resilience is truly commendable. Built to withstand harsh industrial conditions, the ABB SW – 190148 can endure electrical interference, mechanical vibrations, and wide temperature variations without skipping a beat. Operators benefit from its high – level interoperability as well. It integrates effortlessly with a plethora of ABB and third – party devices, making it a flexible choice for system upgrades or expansions. The robust build quality not only enhances its lifespan but also minimizes the need for frequent maintenance, translating into significant cost savings for industrial enterprises over time.

SW – 190148

The ABB SW – 190148 is a versatile solution that finds extensive use across multiple industrial sectors. In power plants, it plays a crucial role in the Supervisory Control and Data Acquisition (SCADA) systems. Here, the SW – 190148 monitors and controls various electrical parameters, such as voltage, current, and frequency, in real – time. By providing accurate and timely data, it helps operators detect potential issues early and take corrective actions, ensuring the stable and reliable supply of electricity.

In automotive manufacturing plants, the ABB SW – 190148 is an essential part of the production line automation. It coordinates the operation of robotic arms, conveyor belts, and other automated machinery, ensuring that each component works in harmony. This not only increases production speed but also improves product quality by reducing errors and inconsistencies in the manufacturing process. Its reliability and performance contribute significantly to the smooth running of these complex industrial operations.

SW – 190148

ABB SW – 190147 – A more compact variant suitable for space – constrained industrial applications, offering similar basic functionality.

ABB SW – 190149 – An advanced model with enhanced processing power, ideal for handling complex data – intensive tasks in large – scale industrial setups.

ABB PM866AK01 – A controller module that pairs perfectly with the SW – 190148, enabling more comprehensive control over industrial processes.

ABB AI810 – An analog input module that works in tandem with the SW – 190148 to expand the system’s data acquisition capabilities.

ABB DO810 – A digital output module that complements the SW – 190148, allowing for precise control of industrial equipment.

ABB CI840 – A communication interface module that can be integrated with the SW – 190148 to enhance the system’s connectivity and data transfer efficiency.

ABB SB822 – An interface module that shares similar communication features with the SW – 190148 and can be used in combination for more complex industrial automation scenarios.

Installing the ABB SW – 190148 requires following a set of precise procedures. When mounting it on the DIN rail, make sure the rail is securely fastened and properly grounded to prevent electrical interference. Ensure that the module is firmly attached to the rail to avoid any vibrations that could disrupt its operation. When making electrical connections, carefully follow the wiring diagrams provided in the user manual. Use high – quality cables and ensure that all connections are tight to avoid loose connections, which could lead to data transmission errors or system malfunctions.

For long – term operation, regular maintenance of the ABB SW – 190148 is crucial. Periodically inspect the module for any signs of physical damage, such as cracks in the casing or loose connectors. Monitor its operating temperature and status indicators regularly to detect any potential issues early. Clean the module regularly to remove dust and debris, especially in environments where these particles tend to accumulate. If any problems arise, ABB provides detailed troubleshooting guides and technical support to help users resolve issues promptly and keep the module running smoothly.

SW – 190148

ABB instills confidence in customers with its unwavering support for the SW – 190148. The company offers a reliable warranty that underscores its belief in the product’s durability. In case of any technical glitches, users can rely on ABB’s extensive global support network. Whether it’s accessing detailed product documentation, seeking remote technical assistance, or arranging for on – site support, ABB ensures that customers have all the resources they need. This commitment to customer assurance, combined with the proven performance of the ABB SW – 190148, makes it a trusted choice for industrial automation and control system applications.

For more information, please click below to learn more:

Reviews

There are no reviews yet.