Description

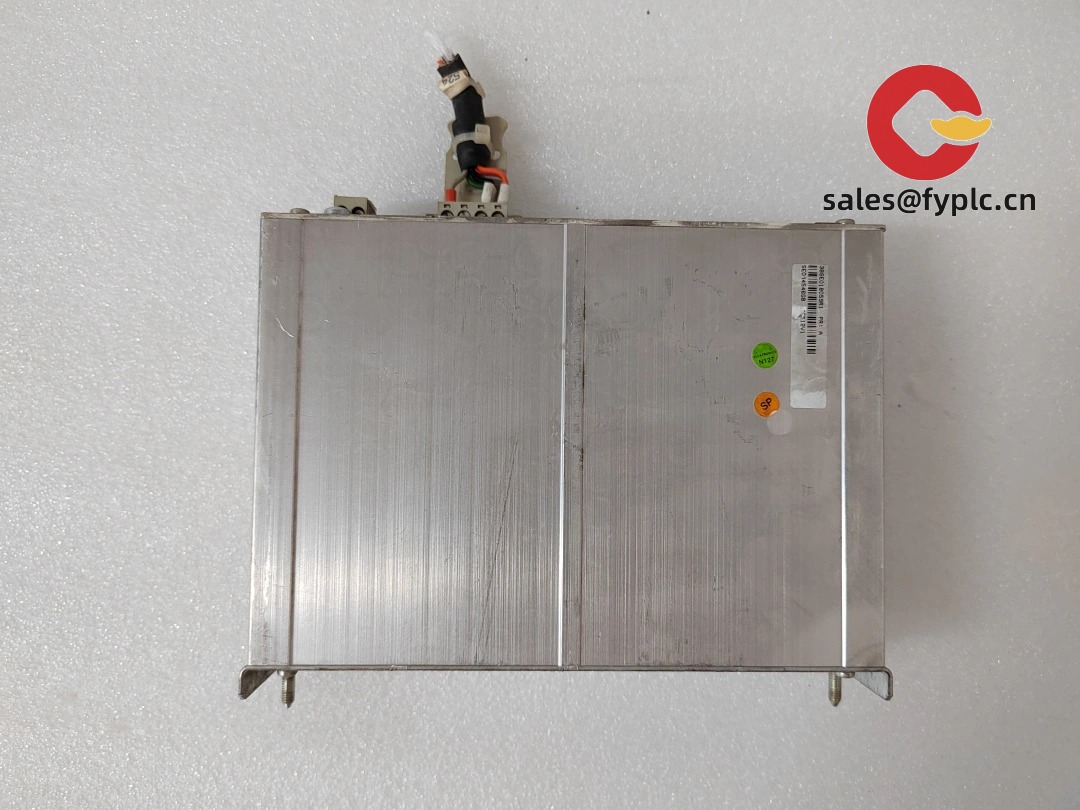

ABB TC512V1 (3BSE018059R1) — High-Integrity Analog Input Terminal for ABB Ability™ System 800xA

Let’s cut to the chase: the TC512V1 isn’t just another analog input module—it’s the go-to terminal when you need precise, galvanically isolated 4–20 mA signal acquisition in safety-critical or high-noise industrial environments. I’ve seen it deployed in offshore compressor stations where EMI from VFDs would normally wreak havoc on readings—and yet, field technicians consistently report stable, drift-free measurements over multi-year intervals. It’s designed specifically for integration into ABB’s System 800xA DCS cabinets, but it also shows up surprisingly often in retrofitted legacy control rooms where engineers are extending the life of existing 800xA I/O racks without swapping out entire backplanes.

Key Features

- 8-channel, 16-bit resolution analog input — Each channel supports 4–20 mA with HART pass-through (read-only), and includes individual galvanic isolation (500 V AC test voltage). In practice, this means you can mix field devices from different zones—say, a pressure transmitter in Zone 1 and a level sensor in Zone 2—without grounding loops or cross-talk.

- Integrated diagnostics & status LED per channel — Not just “OK/FAIL”: it indicates open-circuit, over-range, under-range, and sensor fault conditions separately. One customer in a Finnish pulp mill told us they cut loop-check time by ~40% during commissioning because they could spot a faulty 2-wire transmitter before even touching the wiring.

- Direct compatibility with ABB CI854/CI855 communication interfaces — No firmware bridging or configuration converters needed. You drop it into an 800xA I/O rack, scan it in Control Builder M, and it appears as a native device—no custom GSD files or third-party drivers.

- Wide operating temperature range with conformal coating option — Standard units run from −25°C to +70°C, but many users opt for the factory-applied conformal coating (order code suffix “-C”) when installing near steam traps or in unconditioned offshore switchrooms. From my experience, that coating makes a tangible difference in long-term reliability—especially in high-humidity coastal refineries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB TC512V1 (3BSE018059R1) |

| HS Code | 8537.10 — Boards, panels for industrial control systems |

| Power Requirements | Supplied via backplane (24 V DC ±15%, max. 1.2 A per module) |

| Dimensions & Weight | 135 × 120 × 125 mm (W × H × D); ~850 g |

| Operating Temperature | −25°C to +70°C (standard); −40°C to +70°C with conformal coating (-C variant) |

| Signal Input Type | 8 channels, 4–20 mA DC, 2-wire or 4-wire, HART® v6/v7 read-only |

| Communication Interface | ABB proprietary I/O bus (via CI854/CI855 interface modules); no Ethernet or Modbus native |

| Installation Method | DIN-rail mounted (TS35) inside ABB 800xA I/O cabinets; requires compatible backplane (e.g., S800 I/O rack) |

Application Fields

This module shines where signal integrity and system-level traceability matter more than raw speed. Think offshore oil & gas platforms monitoring wellhead chokes, pharmaceutical cleanroom HVAC loops where regulatory audit trails demand HART-readable tags, or large-scale power generation sites integrating turbine vibration sensors into 800xA for predictive maintenance dashboards. It’s less common in high-speed packaging lines (where you’d lean toward TC522V1 or fast-scan modules), but it’s become almost standard in brownfield upgrades—especially when clients want to reuse existing 4–20 mA infrastructure while moving to modern DCS visualization and alarm management.

Advantages & Value

- No hidden integration tax — Unlike some third-party analog modules, there’s zero cost for ABB engineering support licenses, custom CFC blocks, or certified firmware updates. Configuration lives entirely within Control Builder M.

- Inventory efficiency — Because it shares the same mechanical footprint and mounting as TC511V1 and TC513V1, spares planning gets simpler—many customers stock just one rail-mount bracket and swap modules as needed.

- Long-term TCO edge — While list price sits slightly above generic alternatives, field data suggests 30–50% lower failure rate over 5 years in harsh environments. That translates to fewer unplanned shutdowns—and fewer emergency freight charges for overnight replacements.

- Support continuity — ABB still actively supports this model (as of Q2 2024), including firmware patches for new HART device descriptions and compatibility updates for System 800xA v6.1+.

Installation & Maintenance

Mount only in ABB-certified S800 I/O cabinets with forced-air ventilation (min. 0.3 m/s airflow across module face). Avoid direct proximity to heat-generating components like power supplies or motor starters—leave at least 75 mm clearance above/below. Wiring must use shielded twisted-pair (e.g., Belden 8761), with shields terminated *only* at the TC512V1 end (floating at field device side) to preserve galvanic isolation.

Routine maintenance is light: visual inspection every 6 months for dust buildup (use low-pressure dry air—not compressed shop air with moisture/oil), and verify channel diagnostics during annual loop checks. Firmware updates aren’t required unless adding new HART device types—but if you do update, always back up the current configuration first. Calibration isn’t user-performed; it’s factory-set and traceable to NIST standards. Should drift exceed specs (±0.05% of span), return to ABB-authorized service center.

Quality & Certifications

CE marked (2014/30/EU EMC, 2014/35/EU LVD), UL 61010-1 listed (File E224010), RoHS 2011/65/EU compliant, and ISO 9001:2015 certified production. ABB warranties the TC512V1 for 365 days from shipment date against defects in materials and workmanship. Warranty claims require proof of purchase and module serial number—no restocking fees if returned within 30 days of delivery.

Our order placement process & guarantees:

• Delivery: 1 week for in-stock units (we typically hold 12–18 units globally); longest lead time is 4 weeks.

• Payment: 50% advance, balance before dispatch.

• Shipping: Fedex, UPS, or DHL Express—fully trackable, insured, and customs-cleared.

• Warranty: Full 365-day coverage—no fine print on environmental conditions or installation method.

Reviews

There are no reviews yet.