Description

ABB TC520 — Compact Temperature Controller for Precision Process Loops

One thing I appreciate is how the TC520 fits where bigger controllers can’t—think tight-panel retrofits in aging HVAC control cabinets or small-batch food processing lines where space and wiring simplicity matter more than flashy displays. It’s not a full-featured DCS node, but it reliably handles single-loop temperature regulation with surprising flexibility. A customer in southern Germany recently replaced three legacy Omron E5CC units with TC520s on their jacketed fermentation tanks—and reported smoother ramp-up profiles and fewer manual tweaks during seasonal ambient shifts.

Key Features

- Auto-tuning PID + adaptive gain scheduling — Learns process dynamics over time; especially useful for loads with variable thermal mass (e.g., batch ovens or extruder barrels).

- Universal input (thermocouple/J/K/T/E/N/R/S, RTD Pt100/Pt1000, 0–10 V / 4–20 mA) — No jumper changes needed; configuration done via front keys or optional ABB EDS software.

- Dual relay outputs (SPDT, 3 A @ 250 VAC) — Handles both heating and cooling control in one unit—no external interlock logic required in many cases.

- Local display with intuitive 4-button interface — Bright LED, readable at 3 m; menus avoid nested layers, which helps maintenance techs who only touch it quarterly.

- Optional Modbus RTU (RS-485) — Not built-in by default; requires ordering suffix “-M” (e.g., TC520-M). In practice, most users adding comms go this route rather than upgrading to a full AC500 controller.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB TC520 (standard version, no comms) |

| HS Code | 9032.20 — Electronic temperature controllers, industrial type |

| Power Requirements | 20–230 VAC/VDC ±10%, 50/60 Hz; consumption ≤ 5 VA |

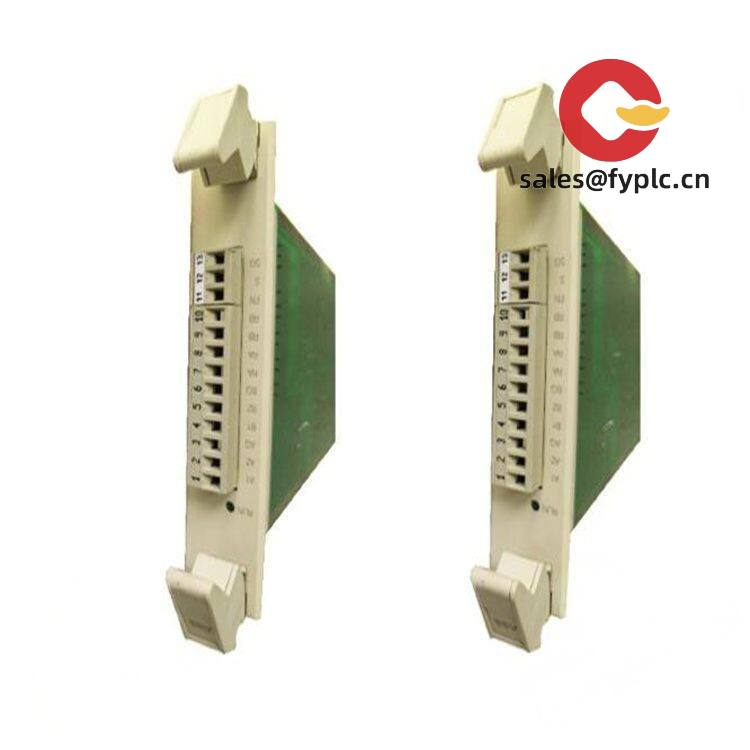

| Dimensions & Weight | 96 × 48 × 115 mm (DIN rail mount), ~280 g |

| Operating Temperature | −10 °C to +60 °C (derating starts above 50 °C) |

| Signal Input Types | Thermocouples (J/K/T/E/N/R/S), RTDs (Pt100/Pt1000), 0–10 V, 0–20 mA, 4–20 mA |

| Output Types | 2 × SPDT relays (3 A / 250 VAC); optional SSR output (-S suffix) or analog retransmission (-R) |

| Communication Interfaces | None standard; Modbus RTU via RS-485 with TC520-M variant |

| Installation Method | Top-hat DIN rail (TS35), vertical orientation recommended; IP20 enclosure |

Application Fields

The TC520 shows up most often where precision matters but budgets don’t justify full PLC integration: sterilization autoclaves in medical device plants, drying zones on coating lines, thermal oil circuits in plastic injection molding, and even lab-scale pilot reactors. It’s also common in OEM equipment—like those compact steam irons used in textile pre-treatment lines—where vendors embed it as a certified, drop-in thermal regulator. From my experience, it tends to underperform only when paired with very slow-response sensors (e.g., large-well thermowells in high-viscosity fluids), where loop tuning gets sluggish without external derivative action.

Advantages & Value

If you’re comparing controllers for a mid-volume production upgrade, the TC520 offers real procurement advantages: ABB’s global spare parts network means replacement modules ship fast—even from regional hubs in Dubai or São Paulo. Compatibility with existing ABB signal conditioners (like the MBS series) reduces engineering overhead. And because it shares firmware architecture with the TC510 and TC530, training and documentation reuse is straightforward across sites. One client cut their average commissioning time per loop by ~35% after switching from custom-programmed micro-PLCs to TC520s—mostly due to eliminating ladder logic validation steps.

Installation & Maintenance

Mount it in a well-ventilated cabinet meeting IEC 61439-1 standards—avoid stacking directly above heat-generating drives. Keep sensor wiring shielded and separated from power cables (minimum 20 cm gap, or use separate conduits). For safety: always disconnect power before terminal access, and verify sensor continuity before first power-on—open-circuit faults can trigger false alarms that lock out outputs. Routine maintenance is light: check relay contacts annually if cycling >10×/hour; clean display vents every 6 months in dusty environments; firmware updates are rare (ABB typically issues <2 per year), but when available, they’re applied via USB-to-RS232 adapter and free EDS software.

Quality & Certifications

CE marked (2014/30/EU, 2014/35/EU), UL 61010-1 listed (E47652), RoHS 3 compliant, and tested to IEC 61000-4 immunity standards (surge, ESD, burst). ABB backs it with a 365-day warranty—no registration required, just keep your invoice. In most cases, failed units are replaced outright rather than repaired, which keeps downtime predictable.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from shipment date

• Delivery: 1 week for in-stock units (most TC520 variants held in EU warehouse)

• Max lead time: 4 weeks for special configurations (e.g., TC520-M-S)

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express — fully tracked, door-to-door

Reviews

There are no reviews yet.