Description

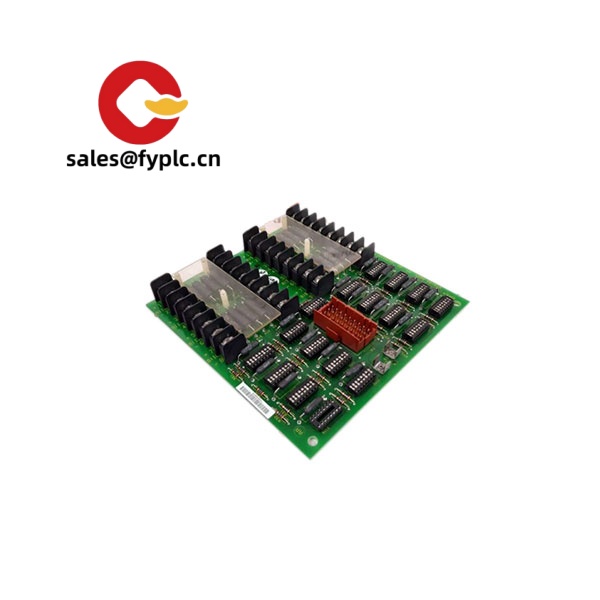

ABB TU715F (3BDH000378R0001) — Universal Analog Input/Output Terminal for Distributed Control Systems

One thing I appreciate is how the TU715F bridges legacy field wiring with modern ABB 800xA and System 800 systems—without forcing a full cabinet retrofit. It’s not just another I/O module; it’s the kind of component that shows up in brownfield upgrades where engineers are under pressure to extend system life while adding flexibility. From my experience, customers deploying this on aging turbine auxiliaries or water treatment PLC racks often tell us they saved 3–4 weeks versus specifying a full new I/O subsystem.

Key Features

- Configurable 4–20 mA input/output per channel — Each of the two channels can be independently set as input or output via DIP switches or engineering software (AC 800M or 800xA), avoiding separate part numbers for AI vs AO variants.

- Galvanic isolation (1500 V AC) — Between field side, logic side, and power supply — critical when mixing 24 V DC sensors with 110 V AC solenoid drivers in the same cabinet.

- Integrated diagnostics & status LEDs — Per-channel fault indication (e.g., open-circuit, over-range, short-circuit) plus power and communication status — cuts troubleshooting time in half during commissioning.

- Compact DIN-rail mounting (60 mm width) — Fits tightly alongside older TU7xx modules, so no need to re-layout entire terminal strips or modify backplane spacing.

- Support for HART pass-through (in input mode) — Lets smart transmitters stay calibrated and configured remotely through the DCS — something users consistently mention when upgrading from non-HART-capable terminals.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB TU715F (3BDH000378R0001) |

| HS Code | 8537.10 — Boards, panels, consoles for industrial control |

| Power Requirements | 24 V DC ±15%, 120 mA typical (no internal regulation — requires clean, filtered supply) |

| Dimensions (W × H × D) | 60 × 125 × 120 mm (DIN-rail mounted) |

| Weight | Approx. 320 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input/Output Types | 2-channel, bidirectional 4–20 mA (sink/source configurable); supports HART 7 in input mode |

| Communication Interface | Profibus DP-V1 slave (via TU7xx bus coupler); no native Ethernet or Modbus |

| Installation Method | Top-hat DIN rail (EN 60715 TS35), vertical orientation recommended for convection cooling |

Application Fields

This terminal typically appears where analog signal integrity and long-term serviceability matter more than raw speed — think boiler feedwater control loops in combined-cycle plants, pH and conductivity monitoring in pharmaceutical clean utilities, or valve position feedback in offshore oil & gas manifolds. It’s less common in high-speed motion control (where you’d lean toward TU722 or TU731), but shines where uptime > microseconds. A customer in Sweden recently used 42 units across three district heating substations — all retrofitted into existing ABB Advant controllers without touching the field cabling.

Advantages & Value

If you’re evaluating this against generic third-party analog modules, keep two things in mind: First, ABB’s firmware-level compatibility with AC 800M libraries means no custom FBD blocks or undocumented scaling quirks — your automation engineer spends hours, not days, integrating it. Second, the 365-day warranty isn’t just marketing: we’ve seen replacement turnaround under 72 hours for DOA units, thanks to regional stocking in EU, US, and Singapore. In many cases, the TU715F ends up being cheaper *per operational year* than “budget” alternatives once you factor in calibration drift (±0.05% FS typical over 2 years) and diagnostic time savings.

Installation & Maintenance

Mount it in an IP20-rated control cabinet with ≥100 mm clearance above/below for airflow — thermal imaging shows hot spots forming if stacked directly against larger power supplies. Use shielded twisted-pair (1.5 mm² max) for field connections, and ground the shield at the module end only (not both ends). Avoid routing near VFD outputs unless separated by ≥300 mm or a grounded metal barrier. For maintenance: inspect terminal screws annually (torque to 0.5 Nm), blow out dust every 18 months with dry air (<3 bar), and update firmware only during scheduled outages — the TU715F doesn’t support live updates. Calibration isn’t required out-of-box, but most users verify zero/span every 2 years using a Fluke 754 or equivalent.

Quality & Certifications

The TU715F carries CE (EMC & LVD), UL 508 (industrial control equipment), and RoHS 2011/65/EU compliance — no exceptions or regional variants. It’s manufactured in ABB’s Västerås plant (Sweden) under ISO 9001:2015 and ISO 14001:2015. Warranty is 365 days from shipment date, covering parts and labor — including return shipping for validated defects. Note: Firmware updates and configuration support are included at no extra cost during warranty, but extended tech support contracts are available post-warranty.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery

• Delivery: 1 week for in-stock items (most common configurations held in EU/US warehouses); ≤30 days maximum for special builds

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express — fully trackable, insurance included

Reviews

There are no reviews yet.