Description

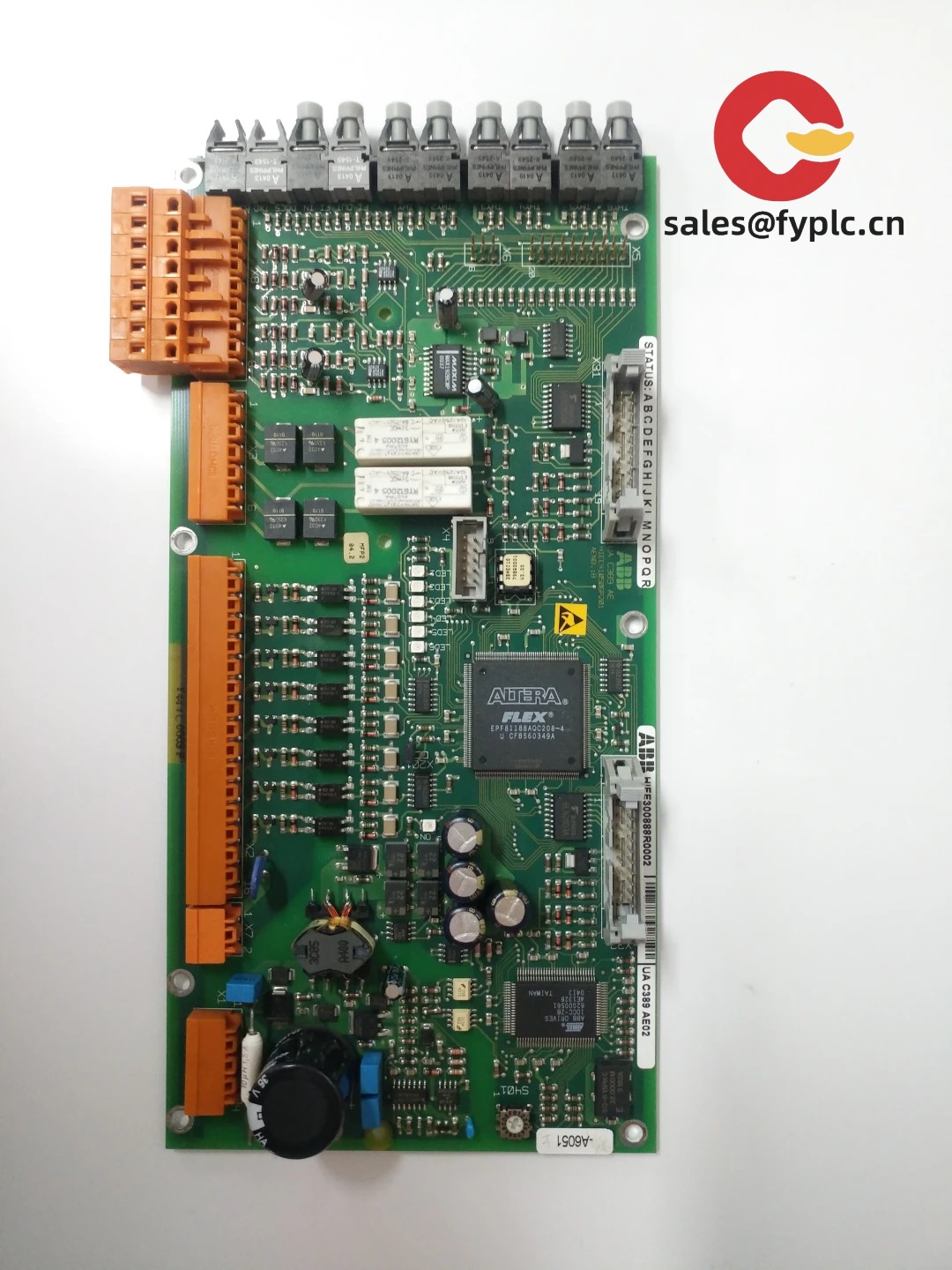

ABB UAC389AE02 (HIEE300888R0002) – System Communication Module for Advant DCS Upgrades and Maintenance

The ABB UAC389AE02, identified by article number HIEE300888R0002, is a plug-in system module used in ABB Advant DCS environments, typically within Advant Master/Advant Controller installations. From my experience, it’s selected when plants need a dependable communication/interface module to keep legacy nodes stable, especially during phased upgrades or when matching existing firmware and hardware revisions is critical to avoid re-engineering. You might notice that AE02 indicates a specific hardware revision that many engineers prefer to keep consistent across a node for predictable performance.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Advant DCS compatibility – Used in Advant Master/Advant Controller systems, ideal for sustaining installed bases without major rewiring.

- Revision-matched module (AE02) – The HIEE300888R0002 variant aligns with AE02 hardware, which in many cases simplifies interchangeability and configuration.

- Backplane-powered – No separate field power; the module receives power through the system rack, reducing wiring complexity.

- System communications role – Designed to handle controller/system-side communications; no direct field I/O, which keeps signal integrity managed by the DCS architecture.

- Service-friendly form factor – Rack plug-in construction for straightforward swap-out during scheduled downtime; ESD-safe handling recommended.

- Long-term lifecycle support – Commonly used to maintain legacy nodes so plants can upgrade on their own schedule.

Technical Specifications

| Brand / Model | ABB UAC389AE02 – HIEE300888R0002 |

| Product Type | Advant DCS system communication/interface module |

| HS Code | 853890 (Parts for industrial control apparatus) |

| Power Requirements | Supplied via system backplane; no external field power required |

| Operating Temperature | Typically 0 to +55°C (industrial cabinet environment) |

| Signal I/O Types | No direct field I/O; functions as a system/communication module |

| Communication Interfaces | Backplane system interface; front service/maintenance port may be present depending on configuration |

| Installation Method | Rack-mounted, plug-in module for Advant DCS system racks |

| Typical Use | Maintaining/expanding Advant nodes, revision-matched replacements, and spares strategies |

Application Fields

Plants running ABB Advant DCS typically use the UAC389AE02 when they need reliable node communications without shifting platform. It’s common in:

- Pulp & paper (continuous processes, web handling)

- Metals and mining (rolling, drives coordination)

- Oil & gas and petrochemical (unit control, utilities)

- Power generation and water treatment (balance-of-plant, auxiliaries)

A maintenance engineer told us they kept a pair of AE02 spares on the shelf to mirror their installed base revisions—this seemed to reduce integration time during unplanned outages.

Advantages & Value

- Reliability – Proven in long-running Advant systems; revision stability is a real benefit when uptime matters.

- Compatibility – AE02 variant aligns with many existing configurations, typically minimizing re-qualification work.

- Cost control – Keeps legacy assets productive without a forced migration project.

- Technical support – Guidance on revision matching, handling procedures, and basic commissioning steps.

Installation & Maintenance

- Cabinet and rack – Install in the designated Advant rack within a ventilated, industrial cabinet (typically 19-inch). Maintain clear airflow front and rear.

- Power and wiring – Module is backplane-powered. Verify rack supply health and grounding before insertion. Use ESD protection and handle by edges.

- Swap procedure – Many sites power down the affected node before replacement; some systems allow controlled online swap, but follow site procedures and risk assessments.

- Configuration/firmware – Keep hardware revision and configuration consistent with the engineering database. Firmware alignment, where applicable, should match your validated build.

- Routine care – Periodically inspect connectors, clean dust with dry air, and check diagnostic LEDs/alarms during shutdown windows.

- Safety – Lock-out/tag-out where required. Confirm I/O impact is isolated before any module change to avoid process upsets.

Quality & Certifications

- Manufacturer quality systems typically aligned with ISO 9001

- CE marking for industrial control environments (common for ABB Advant modules)

- RoHS/UL conformity may vary by production period; check per lot if you have strict compliance requirements

- Warranty: 365 days hardware warranty from shipment

If you’re matching an existing node, share your installed part code and rack position. One thing I appreciate is how much downtime can be saved by confirming revision and configuration upfront—it usually turns a weekend job into a short maintenance window.

Reviews

There are no reviews yet.