Description

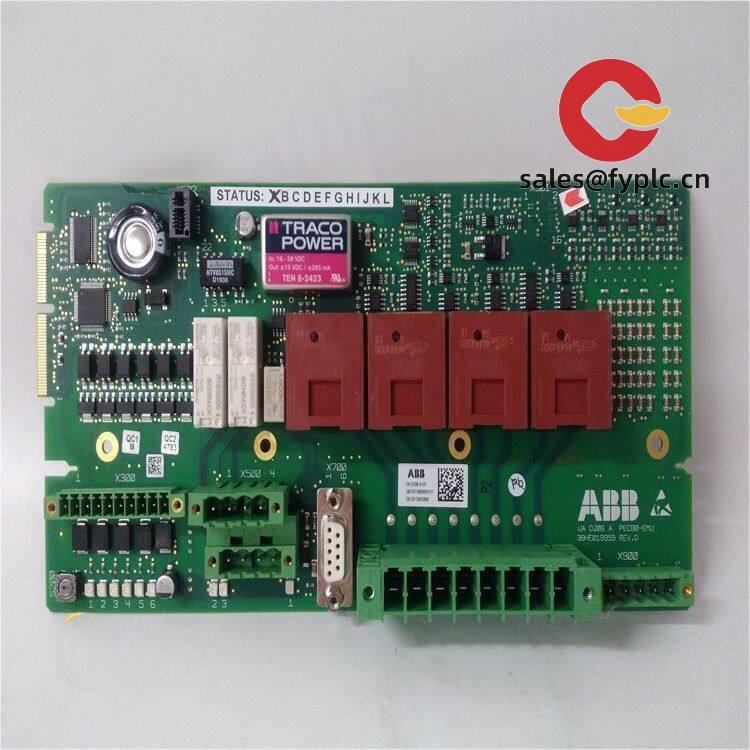

ABB UAD206A101 (3BHE019958R0101) – Mixed I/O Interface Board for ABB Industrial Control and Excitation Systems

The ABB UAD206A101, part number 3BHE019958R0101, is a plug-in I/O interface board used widely in ABB high-performance control platforms—typically in AC 800PEC-based power electronics, drives, and UNITROL excitation systems. From my experience, this module is selected as a reliable analog/digital front-end: it gathers field signals, conditions them, and feeds the control CPU via the ABB backplane. You might notice that sites running rolling mills, marine propulsion drives, wind converters, or synchronous generator excitation often keep this board as a critical spare to minimize downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Mixed-signal I/O front-end: Handles both analog measurement and digital status/control signals for ABB control systems.

- Backplane communication: Connects to the host controller via ABB’s backplane bus; no field wiring directly to Ethernet ports, which keeps noise down in many cases.

- Industrial-grade design: Built for 24/7 environments; conformal coating variants are typically available for harsh conditions.

- Service-friendly layout: Plug-in replacement with guided connectors—maintenance teams usually swap it in minutes when the cabinet is prepared.

- Signal conditioning onboard: Isolation and filtering stages (as applicable) help stabilize readings in noisy motor rooms.

- Diagnostics indicators: Status LEDs (where present) speed up commissioning and fault tracing.

- Compatibility-first approach: Commonly applied with ABB AC 800PEC and UNITROL platforms to maintain system-level compatibility and lifecycle continuity.

Technical Specifications

| Brand / Model | ABB UAD206A101 (3BHE019958R0101) |

| HS Code | 8538.90 – Parts for switching/protection/controls of heading 8535–8537 (industrial control parts) |

| Power Requirements | Supplied via host system backplane (typically derived from 24 VDC cabinet supply) |

| Signal I/O Types | Mixed analog and digital channels; exact channel count depends on board revision and application setup |

| Communication Interfaces | Proprietary backplane interface to ABB controller; no direct fieldbus on the front edge for this board |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated cabinet per ABB guidelines |

| Installation Method | Plug-in PCB module; mounts in ABB card frame/backplane with retention screws |

| Dimensions & Weight | Compact form-factor board; consult the system drawing for exact footprint and mass |

Application Fields

This board shows up in power electronics controls where fast, deterministic I/O is needed. Typical environments include:

- AC/DC drive cabinets (steel and paper lines, mining conveyors, marine propulsion)

- UNITROL-based generator excitation and power plant auxiliaries

- Wind and test-bench converters using AC 800PEC control

- High-performance motion or rolling mill stands where robust noise immunity is essential

A maintenance lead from a paper mill told me they swapped a UAD206A101 in under 20 minutes during a night shift—no software changes, just careful ESD handling—and the drive line was back at speed before the next reel change. That’s typically the kind of low-drama service event plants want.

Advantages & Value

- Reliability: ABB boards like this are built for continuous operation and stable signal integrity.

- Compatibility: Designed to work within ABB control ecosystems (AC 800PEC / UNITROL), reducing integration risk.

- Lifecycle support: Keeps legacy and current cabinets serviceable—cost savings versus wholesale redesign.

- Maintenance speed: Plug-in architecture shortens MTTR, which in many cases saves far more in downtime costs than the part itself.

- Quality traceability: Clear part coding (3BHE019958R0101) supports documentation and spare part management.

Installation & Maintenance

- Cabinet conditions: Install in a clean, ventilated enclosure; maintain airflow paths and avoid heat sources directly beneath the board.

- Grounding & shielding: Bond cabinet PE properly; route shielded signal cables with single-point grounding to minimize noise.

- Backplane integrity: Inspect card guides and connectors; reseat with even pressure and secure retention screws.

- ESD handling: Use wrist straps and antistatic packaging; avoid touching component pins or analog front-end areas.

- Routine checks: Quarterly visual inspection for dust, discoloration, or loose connectors; clean with dry air per site policy.

- Firmware/config: If the application uses controller-resident firmware parameters, back up settings before replacement; restore and verify I/O scaling after swap.

Quality & Certifications

- CE marking: Conforms as part of the complete ABB system

- ISO 9001 manufacturing: Produced under ABB’s quality management system

- RoHS: Typically compliant for standard variants

- Warranty: 365 days (exchange/repair per inspection)

Supporting Components (Commonly Paired)

- ABB AC 800PEC controller and carrier backplane (host CPU and rack)

- UNITROL excitation platform components (for generator applications)

- Shielded cable sets and terminal adapters for analog/digital field wiring

- Filtered 24 VDC power supply modules and EMC cabinet accessories

Note: Channel counts and exact I/O mapping can vary by system configuration and board revision. If you share your cabinet type and controller setup, I can match the UAD206A101 to the correct backplane slot and provide a wiring/commissioning checklist.

Reviews

There are no reviews yet.