Description

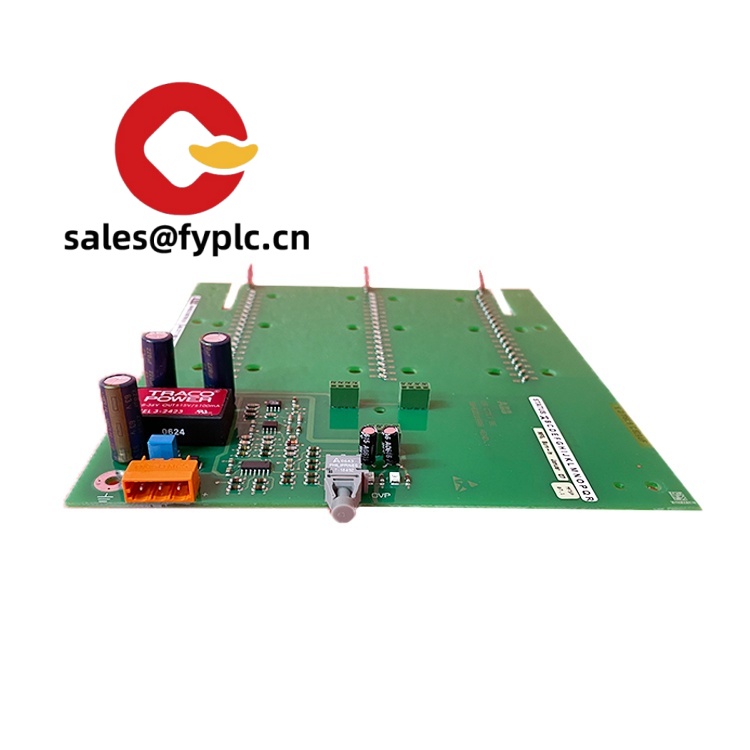

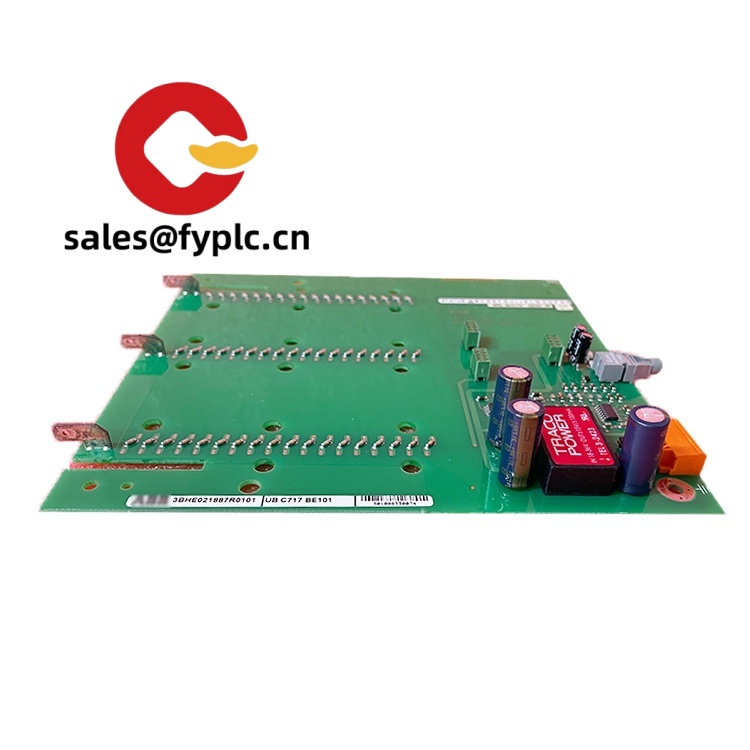

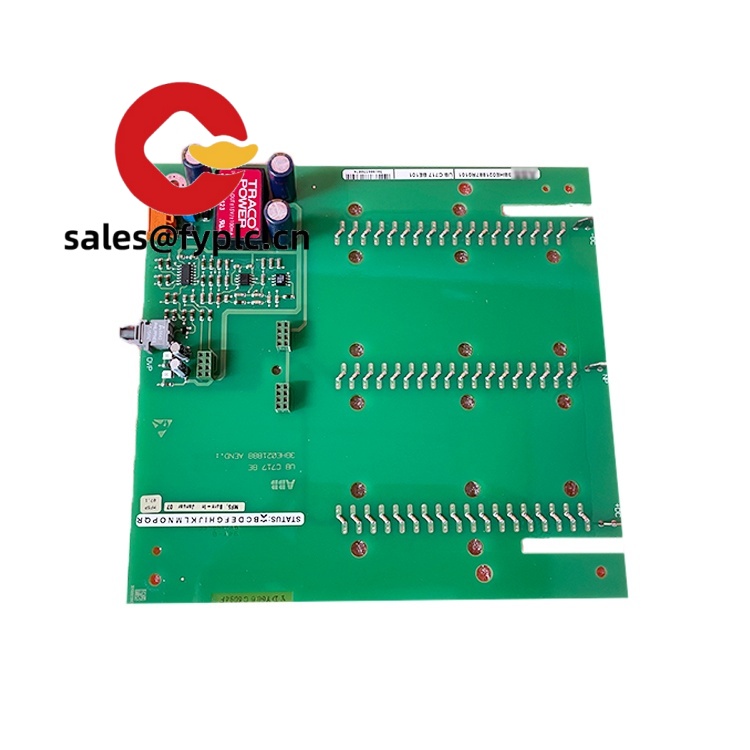

ABB UBC717BE101 (3BHE021887R0101) – Bridge/Excitation Control Board for UNITROL Systems

The ABB UBC717BE101, part number 3BHE021887R0101, is a control board used in ABB UNITROL excitation platforms to manage and supervise the thyristor bridge for generator or synchronous motor field control. From my experience, this board typically sits in the system rack and provides the timing, interlocks, and interface signals the exciter needs to run safely and efficiently. If you’re maintaining a UNITROL-based AVR or planning a like-for-like replacement in a retrofit, this module is a familiar, reliable option that avoids surprises in commissioning.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment, balance prior to delivery

- Express options: FedEx, UPS, DHL

- Testing: Basic functional check before dispatch, with packing designed for sensitive electronics

Key Features

- UNITROL rack compatibility – Designed to install as a plug-in module within ABB excitation cabinets, minimizing wiring changes.

- Bridge firing supervision – Typically handles synchronized gate pulse generation and protection interlocks for the thyristor bridge.

- Fiber-optic trigger outputs – In many cases, fiber links are used for noise-immune gate control to the power stage.

- Analog/digital feedback handling – Supports common analog measurement and discrete status inputs used by the AVR logic.

- Backplane bus interfacing – Communicates over the system backplane for timing, command, and diagnostic data exchange.

- Service-friendly form factor – Front extraction handle and guided rails; a typical swap can be done quickly during planned downtime.

Technical Specifications

| Brand / Model | ABB UBC717BE101 – 3BHE021887R0101 |

| Product Type | Excitation bridge control board (UNITROL family) |

| HS Code | 8538.90 (Parts for boards, panels, consoles for electric control) |

| Power Requirements | Supplied via system backplane, typically 24 VDC nominal |

| Operating Temperature | 0 to +55°C (control cabinet environment) |

| Signal Input / Output | Fiber-optic gate trigger outputs; analog measurement inputs (typical AVR feedback); discrete I/O for status/interlocks |

| Communication Interfaces | System backplane bus; service interface as per UNITROL configuration |

| Installation Method | Plug-in rack module with front handle; secured via guides and fasteners |

| Dimensions & Weight | Approx. 233 × 160 mm PCB form factor; ~0.7 kg |

Application Fields

You’ll typically see the UBC717BE101 in generator excitation cabinets across power plants and industrial facilities. Common scenarios include:

- Hydro, gas, and steam turbine generator excitation systems using UNITROL platforms

- Large synchronous motor field control in metals, mining, pulp & paper, and chemical plants

- Refurbishment projects where a direct, model-correct replacement minimizes re-engineering

- Spare strategy for critical units to reduce unplanned downtime risk

Advantages & Value

- Form-fit-function replacement – Keeps control logic and wiring unchanged, reducing commissioning effort.

- High compatibility – Aligns with ABB UNITROL hardware and firmware practices in most cases.

- Operational continuity – A stocked board can cut outage time to a single shift; one customer told us they swapped and re-synchronized within 30 minutes.

- Lower lifecycle cost – Avoids redesign of excitation controls and retraining of site personnel.

- Technical support – We can reference the exact 3BHE021887R0101 marking and revision to help you match firmware and settings.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry, ventilated control cabinet. Maintain ambient temperature within 0…55°C.

- ESD & safety – Power down and lock out before insertion/removal. Use ESD wrist straps and handle the board by its edges/handle.

- Wiring & optics – Verify backplane seating and connector keys. If fiber optics are present, keep end-faces clean and follow bend-radius limits.

- Firmware/settings – Match board revision with the system’s approved firmware and parameter set; back up existing settings prior to change.

- Routine care – Annual cabinet dust cleaning, connector inspection, and a quick visual check for aged capacitors or hot spots is usually enough.

- Functional test – After replacement, perform a controlled start, confirm bridge firing symmetry, and verify alarms/interlocks are clear.

Quality & Certifications

- Manufactured by ABB within ISO 9001 quality systems

- Typically CE-conformant as part of the complete UNITROL cabinet assembly

- RoHS compliance can vary by manufacturing date and revision; we can verify per serial/label on request

- UL listing generally not applicable to individual internal boards (applies at cabinet/system level)

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.